0 maintenance and service (cont’d), 2 maintenance procedures (cont’d), 5 heat pump maintenance (cont’d) – Reznor ZQYRA Unit Installation Manual User Manual

Page 66

Form I-ZQYRA P/N 260414R5, Page 66

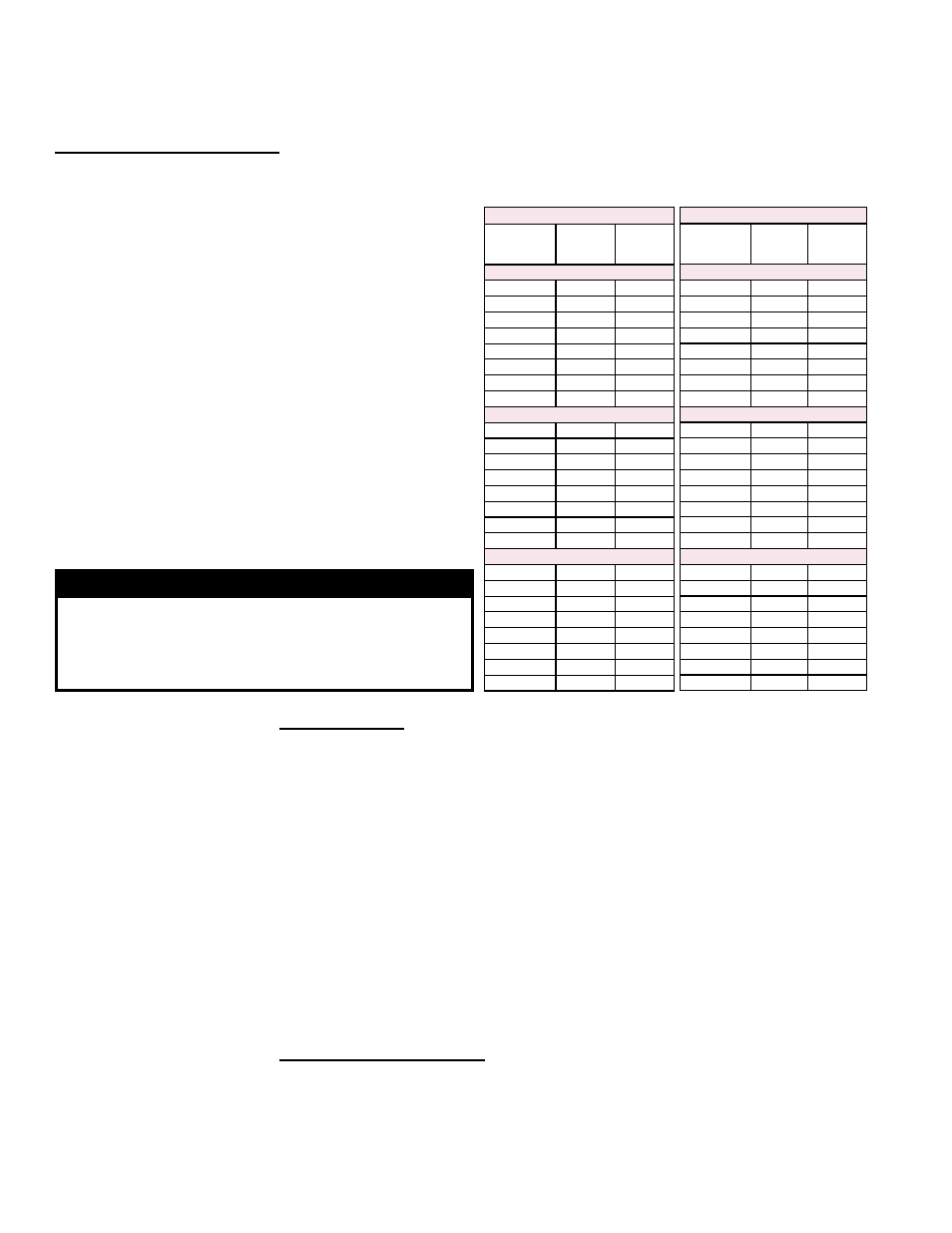

Refrigerant Charge and Check - The unit is factory charged and should require no further adjustment at startup.

Follow these steps to check the refrigerant charge.

NOTE: System charging is not recommended below 70°F (21°C).

1. Attach gauge manifolds and operate the unit in test mode.

2. Set the unit to its nominal airflow (Paragraph 9.3.1).

ZQYRA-8: 800 cfm supply and 1600 cfm exhaust

ZQYRA-12: 1200 cfm supply and 2400 cfm exhaust

3. Turn the wheel off and run the unit in cooling mode until

system stabilizes (approximately 5 minutes).

4. Compare the normal operating pressures in the tables

(right) to the pressures obtained from the gauges.

Minor variations in these pressures may be expected due

to the differences in installations. Significant differences

could mean that the system is not properly charged or

that a problem exists with some component in the system.

Correct any system problems before proceeding.

5. If discharge pressure is high, remove refrigerant from the

system.

If discharge pressure is low, add refrigerant to the system.

Add or remove charge in small increments. Continue

check until pressures are determined to be correct.

WARNING

Do not release refrigerant to the atmosphere.

When adding or removing refrigerant, the

qualified technician must comply with all

national, state/province, and local laws.

ZQYRA-8

Outside Air

Temperature

(ºF)

Suction

Pressure

±5 psig

Discharge

Pressure

±10 psig

Return Air Temperature is 75ºF

70

86

344

75

93

363

80

100

383

85

108

404

90

117

425

95

126

447

100

136

469

105

147

493

Return Air Temperature is 80ºF

70

87

357

75

94

376

80

101

396

85

109

417

90

118

439

95

127

461

100

137

484

105

148

507

Return Air Temperature is 85ºF

70

88

370

75

95

390

80

102

410

85

110

431

90

118

453

95

128

475

100

138

498

105

149

522

ZQYRA-12

Outside Air

Temperature

(ºF)

Suction

Pressure

±5 psig

Discharge

Pressure

±10 psig

Return Air Temperature is 75ºF

70

104

307

75

111

323

80

119

339

85

128

357

90

138

375

95

148

394

100

159

413

105

171

433

Return Air Temperature is 80ºF

70

105

317

75

112

334

80

121

351

85

129

369

90

139

387

95

149

406

100

160

426

105

173

446

Return Air Temperature is 85ºF

70

106

329

75

113

345

80

121

363

85

130

381

90

140

399

95

151

418

100

162

438

105

174

459

Coils and Tubing - Inspect the coils for debris, dirt, grease, lint, mold, or any element

which would obstruct heat transfer or airflow. Inspect coils and tubing for physical dam-

age. Inspect feeders, piping connections, coil headers, and return bends for signs of

fatigue, rubbing, and physical damage.

To clean the coils, use the proper tools and follow the instructions carefully to avoid

damaging the coil. Use of a non-acid based coil cleaner is recommended. Due to pos-

sible damage to the coil, high pressure spray is not recommended.

Cleaning Instructions:

1. Verify that the electrical power has been turned off and disconnect switch locked.

2. Open the coil cabinet door.

3. Use a soft brush to remove any dirt and debris from both sides of the coil.

4. Spray with cold or warm (not hot) water and a cleaning solution (non-acid based

coil cleaner is recommended). Due to possible damage to the coil, high pressure

spray is not recommended. First spray the leaving airflow side, then the inlet

airflow side. As much as possible, spray the solution perpendicular to the face of

the coil. Follow the instructions on the cleaning solution. When cleaning process is

complete, rinse both sides with cool, clean water.

Condensate Pan and Drain - The combination of airborne particles and moisture

can result in algae formation in the drain pan and trap. The drain pan and trap must

be cleaned regularly to avoid blockage that can slow or stop water flow, resulting in

backup into the cabinet. Clean the drain pan, trap, and piping. After cleaning, re-install

all parts and fill the trap with water to ensure proper operation.

10.0 Maintenance

and Service

(cont’d)

10.2 Maintenance Procedures (cont’d)

10.2.5 Heat Pump Maintenance (cont’d)