0 maintenance and service (cont’d), 3 troubleshooting (cont’d), 1 general troubleshooting (cont’d) – Reznor ZQYRA Unit Installation Manual User Manual

Page 68

Form I-ZQYRA P/N 260414R5, Page 68

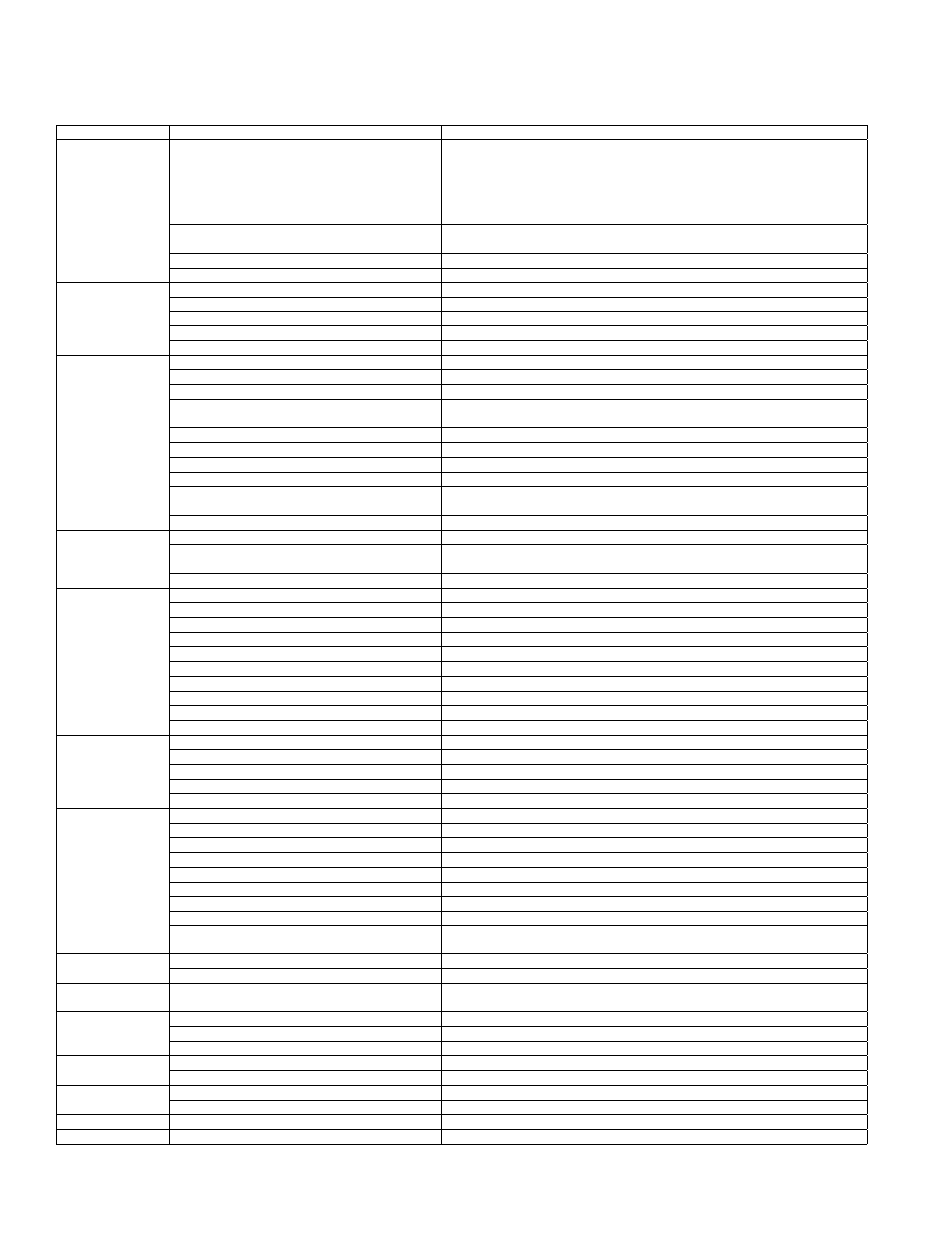

Symptom

Possible Cause

Corrective Action

“High suction

pressure” (cont’d)

Expansion valve not secured to suction line.

"Check the thermal expansion valve, ensure bulb is insulated. Check

superheat. If superheat is high, then valve is out of control and pegged wide

open.

• Check bulb for contact.

• Adjust valve for superheat.

• Replace valve powerhead or valve.

Thermostatic expansion valve pressure limit

feature incorrect or inoperative (overfeeding).

Check bulb location and clamping. Adjust superheat. Replace expansion

valve power head.

Room load too large.

Reduce the load or add more equipment.

Overcharged.

Check pressures and subcooling.

"High discharge

pressure"

Thermal expansion valve setting.

Check thermal expansion setting and calibrate superheat.

Too much refrigerant.

Remove excess refrigerant.

Non-condensable in system.

Remove non-condensable from system.

Discharge service valve partially closed.

Open valve.

High load conditions.

Add more equipment or reduce load.

“Low suction

pressure.”

Refrigerant undercharge.

Check pressures and subcooling.

Compressor rotation backward.

Interchange any two wires from 3 phase disconnect. See Paragraph 7.1.

Loose blower, pulley or belts.

Check drive pulley alignment, belt tension.

"Low entering air temperature (low load

condition)."

Check entering air wet bulb conditions.

Refrigerant leak.

Check system for leaks. Repair leaks and add refrigerant.

Evaporator dirty or iced up or airflow restricted. Check defrost system. Clean the coil. Check fan operation. Check airflow.

Plugged liquid line filter-drier.

Replace filter-drier.

Improper suction pressure regulator setting.

Check setting and correct as required.

Expansion valve defective, superheat too high,

or valve too small.

Adjust valve for proper superheat or replace the expansion valve if too small

or defective.

Moisture in system.

Reclaim refrigerant, check for leaks, and recharge.

"Low discharge

pressure."

Insufficient refrigerant charge.

Check subcooling, check for leak. Repair leak and add refrigerant.

Defective or improperly adjusted expansion

valve.

Check superheating and adjust thermal expansion valve.

Low suction pressure.

See “Low suction pressure”.

"Compressor short

cycles."

Thermostat location or malfunction.

Check thermostat.

Improper refrigerant charge.

Check subcooling; verify superheat.

Defective high or low pressure control.

Check high or low pressure switch.

Liquid floodback.

Possible tight bearings.

Defective expansion valve.

Check thermal expansion valve and superheat.

Poor air distribution.

Check ductwork for recirculating.

High discharge pressure.

See “High discharge pressure”.

Leaking discharge valves in compressor.

See “High suction pressure”.

Low airflow at evaporator(s).

Check blower operation and airstream restrictions.

Incorrect unit selection (oversized).

Contact factory.

"Compressor loses

oil."

Refrigerant leak.

Check system for leaks. Repair leaks and add refrigerant.

Short cycling.

Check low pressure control settings.

Refrigerant flood back.

Check thermal expansion valve setting. Check for refrigerant overcharge.

Improper piping or traps.

Verify proper piping slopes.

Reheat flush cycle inadequate.

Contact factory.

"Running cycle

is too long or

unit operates

continuously."

Refrigeration undercharged.

Check subcooling.

Dirty filter or evaporator coil.

Check filter, coil and airflow.

Dirty or clogged condenser coil.

Check coil and airflow.

Air or other non-condensables in system.

Check equalized high side pressure with equivalent outdoor temperature.

Defective compressor.

See “High suction pressure”.

Restriction in suction and liquid line.

Check for restrictions in refrigerant circuit.

Control contacts stuck.

Check wiring.

Excessive load.

Add more equipment or reduce room load.

"Too low of a system thermostat setting or

defective thermostat."

Adjust or replace thermostat.

"Liquid line is too

hot."

Refrigerant undercharge.

Adjust the charge by subcooling.

High discharge pressure.

See “High discharge pressure”.

"Liquid line is

frosted or wet."

Restriction in liquid line.

Clear restriction upstream of point of frosting.

"Suction line is

frosting."

Insufficient evaporator airflow.

Check airflow; check filters; check drive for loose parts or belts.

Restriction in suction or liquid line.

Restriction upstream of point of frosting.

Malfunctioning or defective expansion valve.

Check bulb of thermal expansion valve.

"Frost on

evaporator coil."

Hot gas bypass valve not functioning properly.

Check valve. If defective, replace.

Manual hot gas bypass valve closed.

Open valve.

Wheel Not

Operating.

Wheel binding.

Adjust wheel; clear restriction.

Wheel motor defective or belt loose.

Adjust or replace belt; or replace motor.

Fan Will Not Start Loose wiring.

Check all connections.

Unit Will Not Start Improperly wired.

Verify with the unit wiring diagram and Paragraph 7.0.

10.3 Troubleshooting (cont’d)

10.0 Maintenance and Service (cont’d)

10.3.1 General Troubleshooting (cont’d)