Haltech E8 User Manual

Page 90

Haltech E11/E8 Instruction Manual

bar due to the interpolation between the two bars.

If you are experiencing difficulties maintaining air to fuel ratio at full throttle, it may be necessary to use the

Full Throttle Map to set the full throttle mixtures. The Full Throttle Map is activated above the value set in

the Full Throttle Threshold in the Fuel Set-up, and has one programmable bar every 500 rpm up to 15500

rpm.

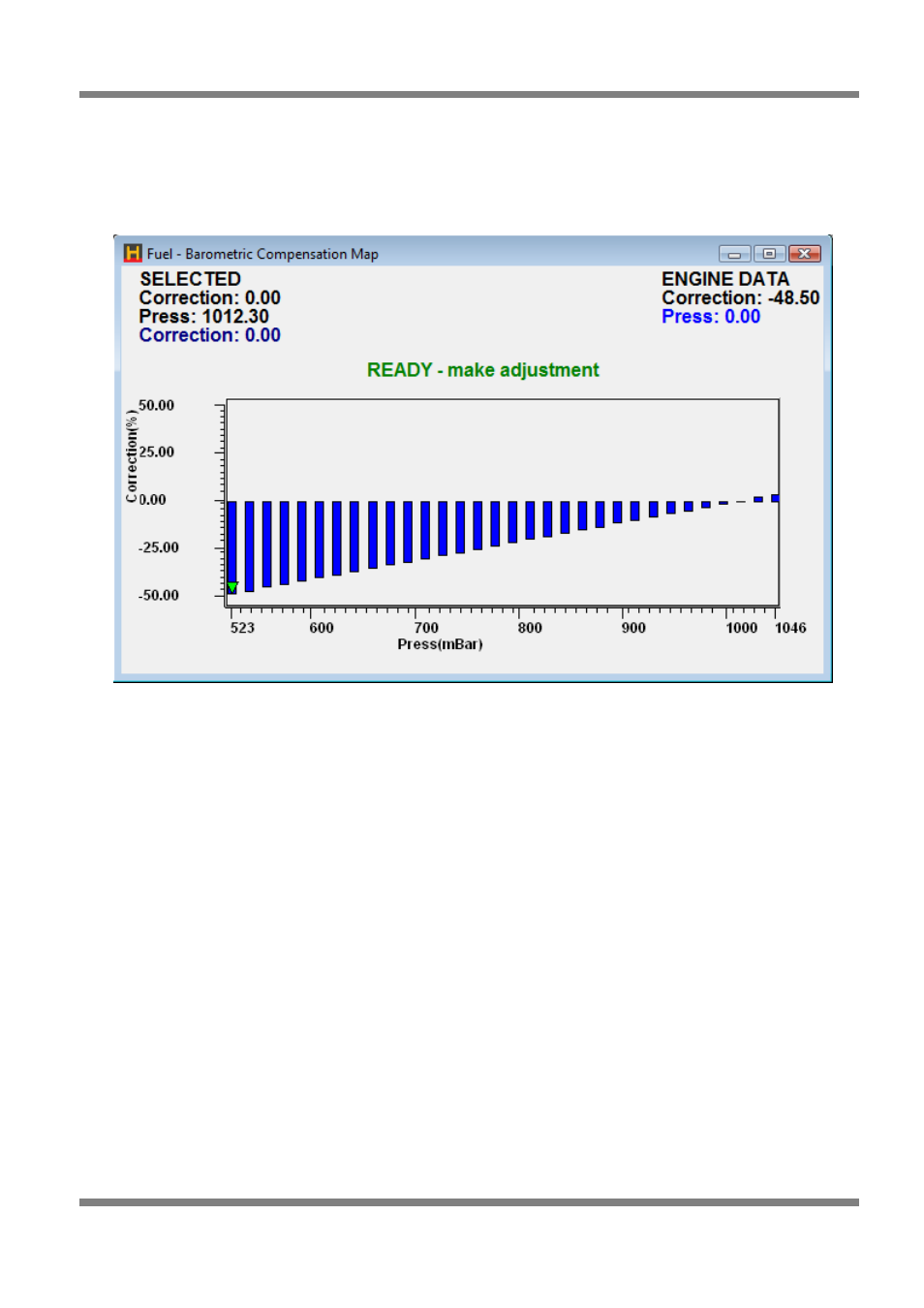

Figure 94 - Barometric Pressure Correction Map

Throttle Pump Maps

The manifold pressure sensor used with the ECU is very fast. It can respond much faster than is required

to track any sudden changes in load on your engine. However, the manifold pressure seen at the sensor

input may not change as quickly as what is seen by the inlets to the combustion chamber, due partly to

the length of the connecting pipe. This delay can be reduced by keeping the length of vacuum hose

between the inlet manifold and the pressure sensor as short as possible. Even with very short vacuum

hose lengths there may still be a lag between a transient pressure occurring and the pressure reaching

the sensor.

Further, when the throttle is cracked open, the sudden change in pressure forces fuel out of atomisation

and onto the manifold walls, so it fails to enter the combustion chamber properly atomised, and the engine

hesitates. This can be corrected by adjustment of the Throttle Pump parameters.

To overcome any lean out during sudden throttle movement, the Haltech system uses a throttle

accelerator pump function. This function delivers extra fuel during sudden throttle movements. The

Throttle Pump is accessed from the Maps Menu.

The throttle pump values should be set up after the fuel and maps are correctly tuned for steady load

running. Attempting to smooth out engine transients before the fuel maps have been optimised for steady

state running may become confusing. The throttle pumps should be adjusted by trial and error to give

optimum throttle response in each rev range. Generally, you may not need much above 3000 rpm, but

could expect much higher values below 1500 rpm.

Note that throttle response can also be affected by poor manifold design. If you have designed your own

inlet manifold you may find that although the engine runs well at steady load it leans out if the throttle is

opened suddenly. This will occur if the fuel injectors are poorly positioned and the fuel is wetting down the

walls of the inlet manifold rather than remaining as a mist.

Page: 90

Copyright © Haltech 2008