Haltech E8 User Manual

Page 51

Haltech E11/E8 Instruction Manual

If the firmware update continues to fail please contact your Haltech dealer.

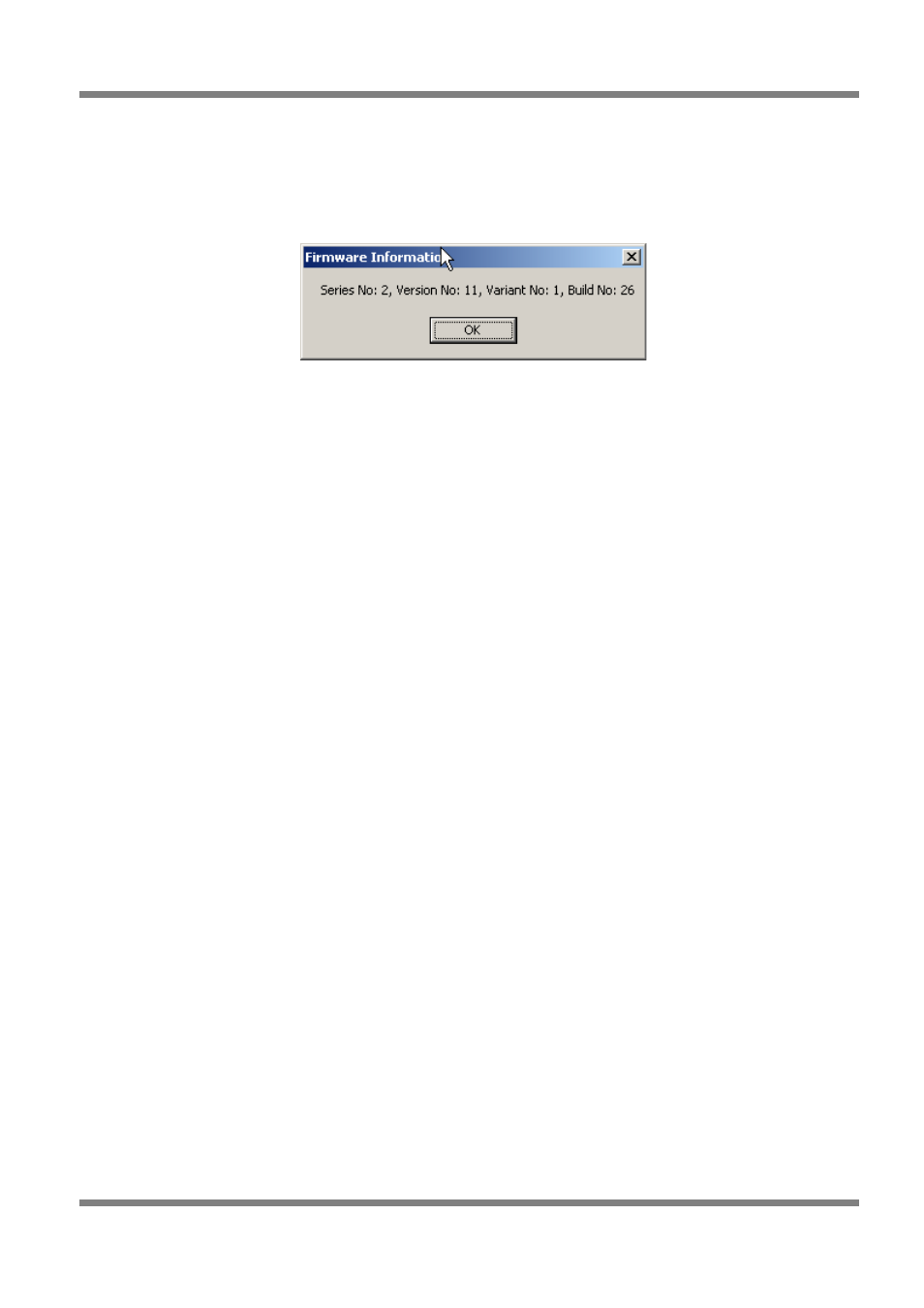

Firmware Version Information

In order to assist in supporting our product, the firmware information may be necessary in order to

diagnose any support issues that may arise. In addition to this purpose, the firmware information is also a

useful way to verify that a firmware update operation has been successfully performed.

Figure 45 - Firmware Version Information

The convention for version numbers is as follows:

Series Number - This number will be incremented when a significant change to the product is made. Any

changes to the map structure or format will result in a new series of firmware.

Version Number

- This number will be incremented when a new feature is added or improvement is made

to the firmware.

Variant Number

- The variant number is used to distinguish mainstream firmware from specialised

firmware used for special applications. Variant 1 is the normal variant number for general release

firmware. Factory boot mode firmware has the variant number of zero.

Build Number -

This number is incremented whenever a version of firmware is released. An increase in

build number indicates a bug fix or minor revision to the operation of the ECU.

Stepper Motor Control

•

Idle Control

- This section refers only to 4 wire stepper motor idle control. For this meathod of idle

control the 2 wires labelled IDLE 1 – IDLE 4 are to be used. These wires can only be used to

control a 4 wire stepper motor style idle speed controller. An idle speed controller with only 2 or 3

wires is a solenoid valve and programmed as a BAC (bypass air control) valve using PWM signals,

this method of idle control is described in the Auxiliary Output Setup section . Refer to the tuning

guide section for a description of how to program both types of idle speed controller.

•

Oil Metering Pump Control

- Some rotary engines have an oil pump for lubrication that can be

controlled electronically to vary the amount of oil injected into the engine. If your rotary engine has

this feature, enable this option. The Feedback Min and Feedback Max values should not need to

change from the factory calibrated values. Setup an ‘Analog Input’ and connect the feedback from

the oil metering pump controller to this input. See analog inputs section for details on setting up

analogue inputs.

Check the Oil Metering Pump map in the maps menu. The preset factory map will be adequate for

most vehicles.

Copyright © Haltech 2008

Page: 51