Haltech E8 User Manual

Page 55

Haltech E11/E8 Instruction Manual

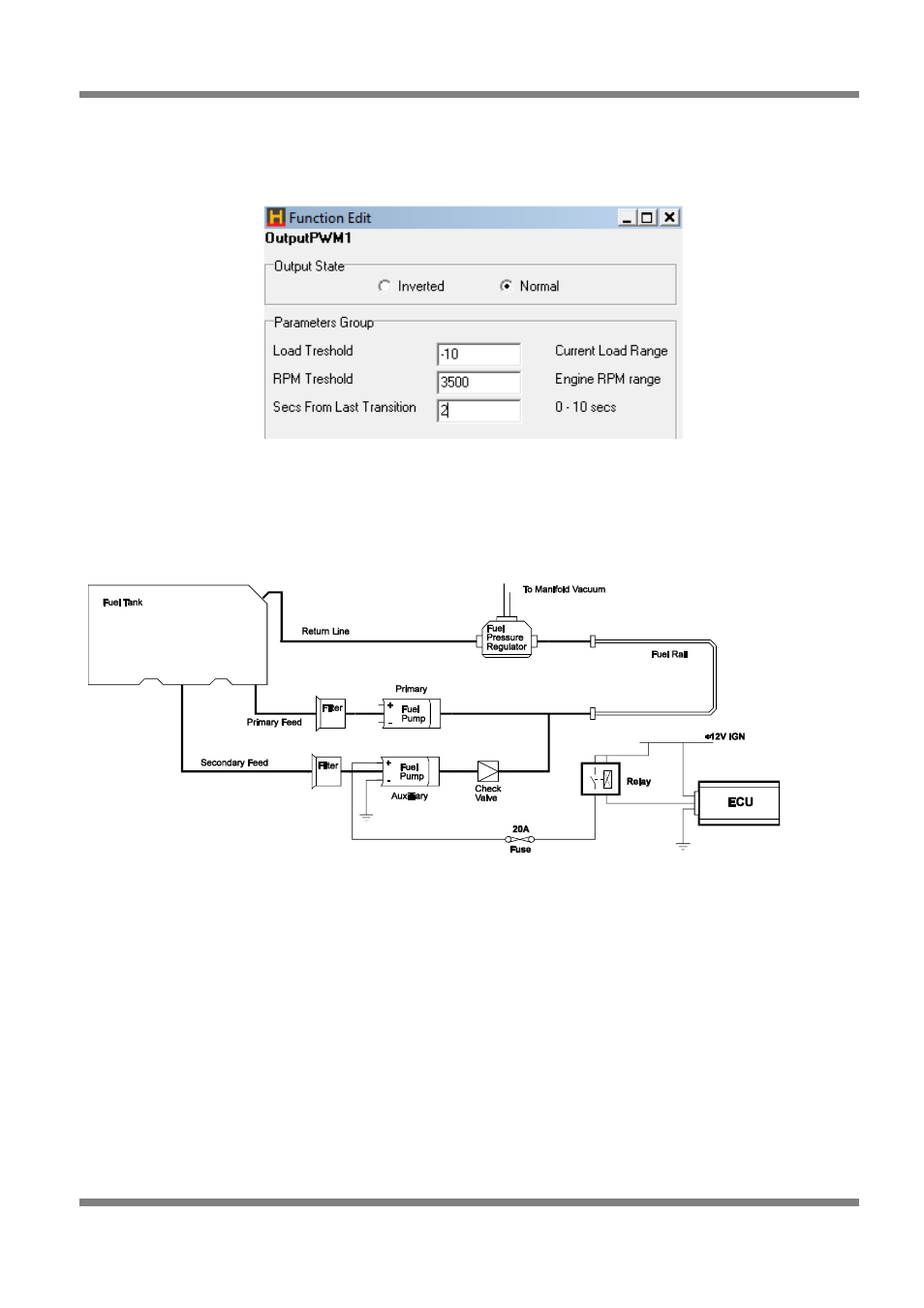

The extra pump must be connected in parallel with the primary fuel pump. The Figure below suggests a

possible layout. The check valve is necessary to prevent fuel from being forced in the wrong direction.

Connect the power to the pump via a relay as shown. Either the positive or negative side may be switched

through the relay.

Figure 50

There are two parameters that define when the Auxiliary Pump will be switched on:

•

Load Threshold

- The load at which the pump will switch on.

•

RPM Threshold

- The RPM at which the pump will switch on.

•

Time - The minimum time between successive on or off transitions.

Figure 51

BAC Idle Control

- BAC idle control uses a valve to allow air to bypass the throttle plate to control idle

speed. The motor used is a solenoid style motor that moves according to the current flowing through the

BAC motor. This is similar to a voice coil in an audio speaker. BAC valve idle control is used to hold

steady the RPM when off the throttle. This method of controlling RPM at idle is done by looking at the

difference between the target idle RPM and the current RPM and adjusting the BAC valve’s output duty

cycle until the difference is zero.

See tuning section for setting up and tuning the BAC valve idle control.

BAC Hi

- BAC high is a form of BAC idle control that is used for 3-wire BAC valves with two coils. These

valves are sprung so that when no coils are energised, the BAC valve sits at 50% open. Two PWM signals

are used to move the coils. One signal moves the valve from 0% to 50% open, while the other signal

moves the valve from 50% to 100% open. The BAC Hi output moves the valve from 50% to 100%. When

the target position for the valve is between 50% and 100%, this output will provide a signal from 0% to

100% duty. All idle control tuning and setup is done with the BAC Hi output. Refer to tuning section below

for details on how to tune your idle control.

Copyright © Haltech 2008

Page: 55