Dyno installation, Removing the dyno from the crate – Dynojet 424x: Installation Guide User Manual

Page 33

S T A T I O N A R Y D Y N O I N S T A L L A T I O N

Dyno Installation

Version 7

In Ground Model 424x/424xLC

2

Automotive Dynamometer Installation Guide

2-9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DYNO INSTALLATION

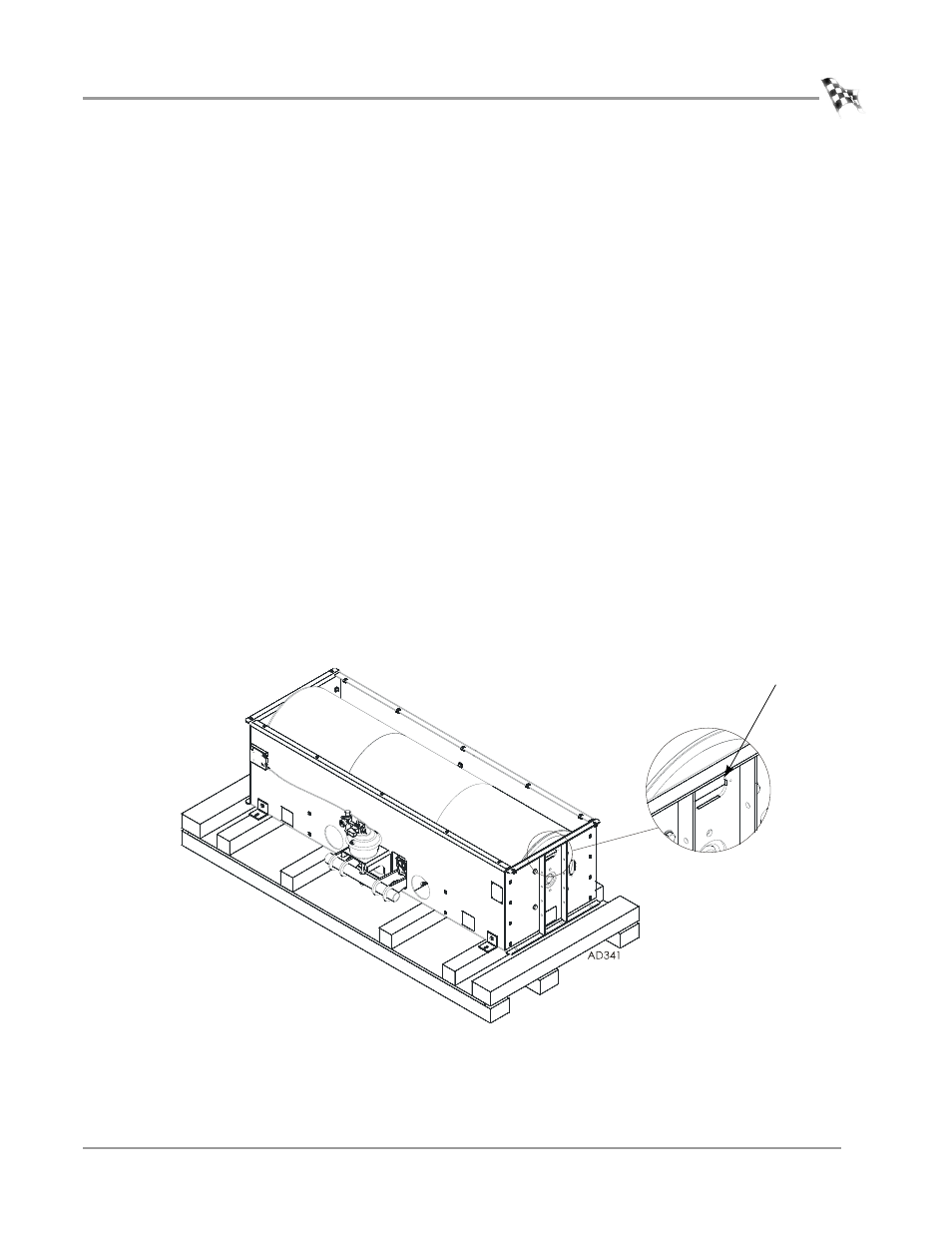

This section will walk you through removing the dyno from the crate and installing

the dyno in your pit. Refer to Chapter 4 for instructions on installing the eddy current

brake.

Note: Refer to Appendix C for instructions on upgrading an existing dyno.

R

EMOVING

THE

D

YNO

FROM

THE

C

RATE

You will need to provide equipment capable of lifting a minimum of 2,114 kg

(4,660 lb.) to lift the dyno off the crate and into position in your dyno room. You will

also need a pair of straps capable of supporting the same weight. Dynojet

recommends using two 2-inch x 6-foot single loop style straps. Refer to “Forklift

Requirements” on page 1-7.

1

Remove the four lag bolts and washers securing the dyno to the crate base using a

9/16-inch socket, open or box end wrench.

2

Route the loop strap through the opening in the dyno frame and through itself.

Pull the strap tight. Do this on each side of the dyno frame.

3

Push the forklift forks together.

4

Place each loop strap over both forks.

Note: The straps must be the same length and meet in the middle. Verify each

loop strap is over both forks to prevent the forks from being pulled apart.

5

Using the forklift, carefully lift the dyno off the crate and move it into position in

your dyno room.

Figure 2-2: Loop Strap Placement

place strap through

opening in dyno frame