Load cell calibration – Dynojet 424x: Installation Guide User Manual

Page 104

In Ground Model 424x/424xLC

2

Automotive Dynamometer Installation Guide

C H A P T E R 4

Load Cell Calibration

4-20

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LOAD CELL CALIBRATION

This section provides instructions for calibrating the load cell(s). The load cell must

be calibrated prior to use. Follow the directions on the screen exactly. Failure to

perform the directions accurately will result in improper torque values.

Note: Repeat these steps for each eddy current brake.

You will need the following parts:

• 35430899

Weight (4)

• 61319001

Calibration Arm Assembly

1

Verify you are in the MakeRun screen.

2

Verify you are connected to the dyno electronics.

Note: For more information on connecting to the dyno electronics, refer to the

WinPEP 7 User Guide (on your WinPEP CD or at www.dynojet.com) or the

WinPEP 7 Online Help.

3

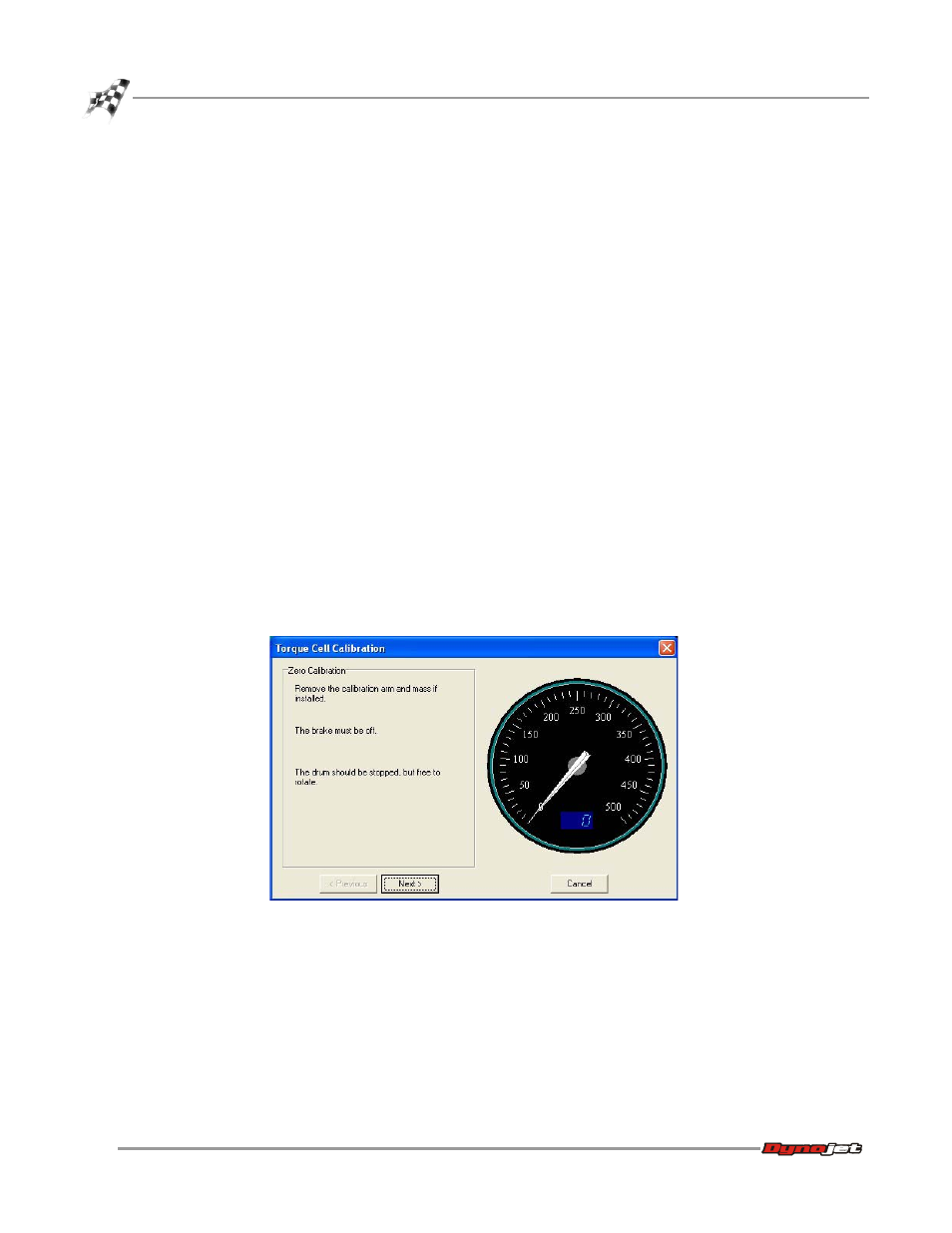

Select Tools

MakeRun Options

Torque Cell Calibration.

Note: Before proceeding, be sure the eddy current brake is free and clear of any

obstructions. There should not be anything resting on the eddy current brake or

the dynamometer drum during this procedure.

4

Click Next to perform the Zero Calibration.

The Calibration window will appear. The hardware is now zeroing out the torque

cell. If the unit does not calibrate, recheck the setup and retry.

Figure 4-21: Zero Calibration Window