Grounding your kinetix 350 drive system, Ground your drive to the system subpanel – Rockwell Automation 2097-Vxxx Kinetix 350 Single-axis EtherNet/IP Servo Drive User Manual User Manual

Page 58

58

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

Chapter 4 Connect the Kinetix 350 Drive System

Grounding Your Kinetix 350

Drive System

All equipment and components of a machine or process system must have a

common earth ground point connected to their chassis. A grounded system

provides a safety ground path for short circuit protection. Grounding your

modules and panels minimize shock hazard to personnel and damage to

equipment caused by short circuits, transient overvoltages, and accidental

connection of energized conductors to the equipment chassis. For CE grounding

requirements, refer to

.

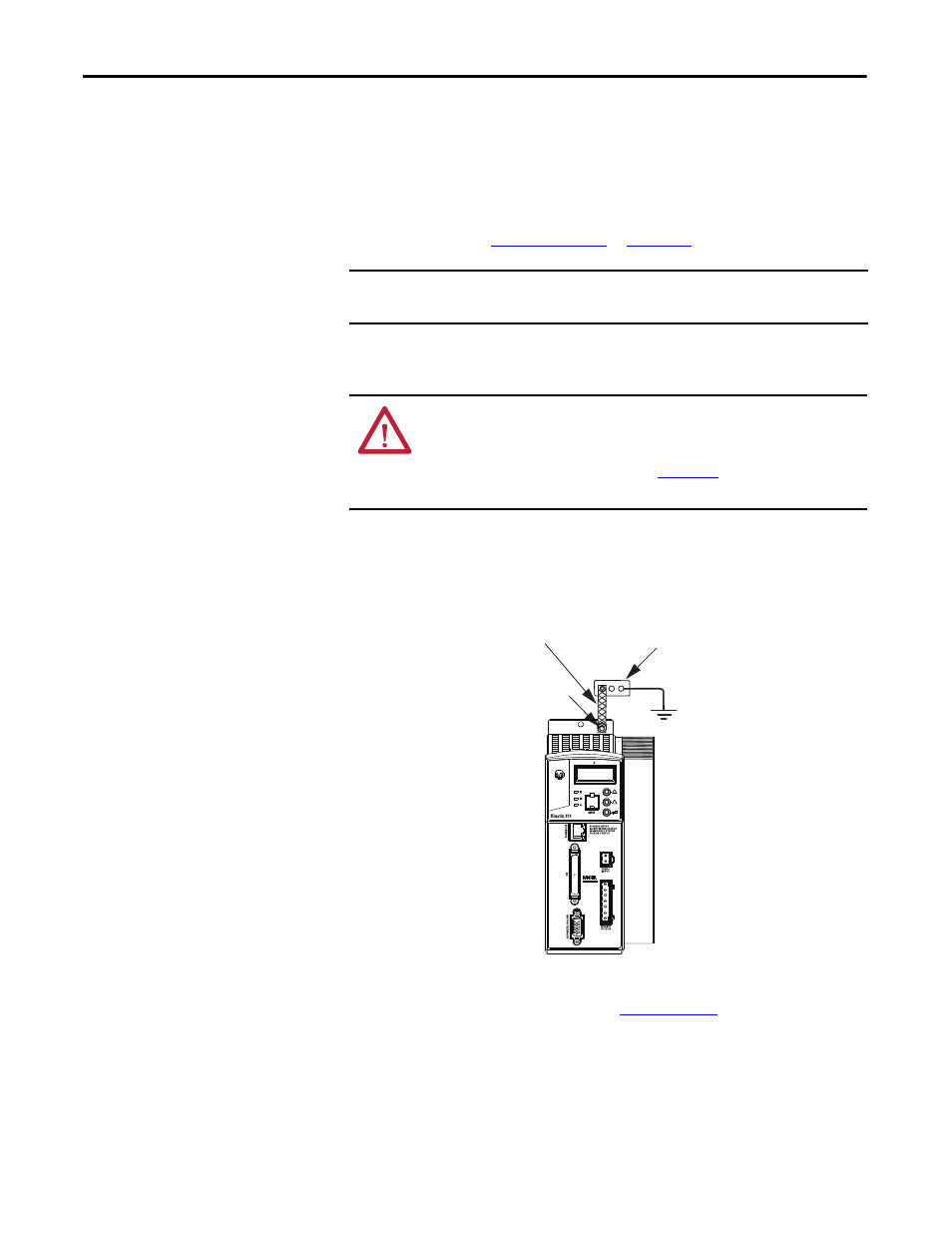

Ground Your Drive to the System Subpanel

If the Kinetix 350 drive is mounted on a painted subpanel, ground the drive to a

bonded cabinet ground bus by using a braided ground strap or 4.0 mm

2

(12 AWG) solid copper wire 100 mm (3.9 in.) long.

Figure 32 - Connecting the Braided Ground Strap Example

For drive dimensions, refer to Product Dimensions in Kinetix Servo Drives

Specifications Technical Data, publicat

IMPORTANT

To improve the bond between the Kinetix 350 drive and subpanel, construct

your subpanel out of zinc plated (paint-free) steel.

ATTENTION: The National Electrical Code contains grounding requirements,

conventions, and definitions. Follow all applicable local codes and regulations

to safely ground your system. Refer to the illustration below for details on

grounding your Kinetix 350 drive. Refer to

for the power wiring

diagram for your Kinetix 350 drive.

Bonded Cabinet

Ground Bus

Ground Grid or Power

Distribution Ground

Braided

Ground Strap

Ground Stud