Rockwell Automation 2097-Vxxx Kinetix 350 Single-axis EtherNet/IP Servo Drive User Manual User Manual

Page 125

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

125

Troubleshoot the Kinetix 350 Drive Chapter 7

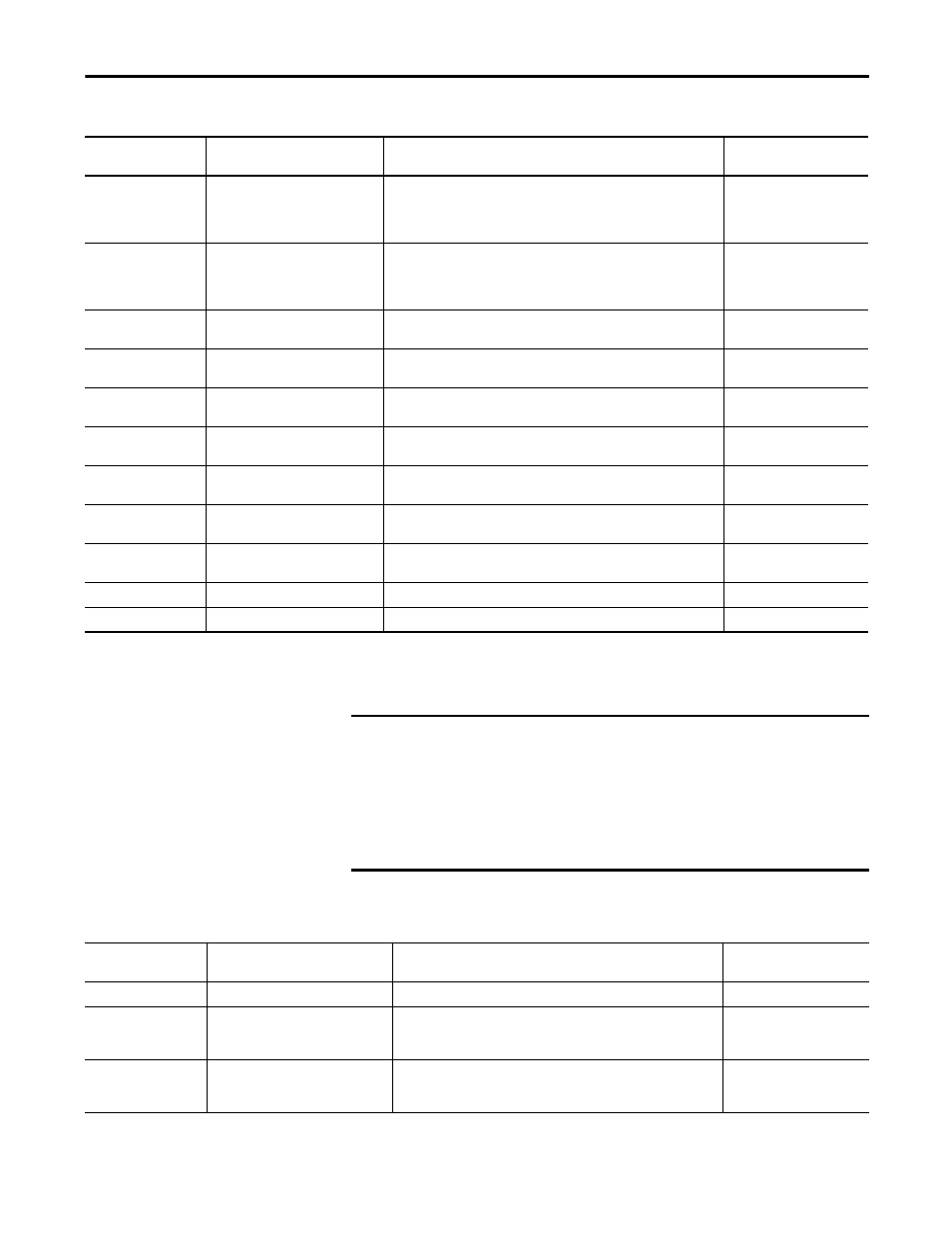

F 43

(1)

Feedback Signal Loss

One or more A/B channel signals from a feedback device are open, shorted,

missing, or severely attenuated. Specifically, the detected voltage levels of

the signals are below the Feedback Signal Loss Factory Limit. The offending

feedback channel is encoded in the associated Fault/Alarm Sub Code.

Disable/Coast

F 45

Feedback Data Loss

The number of consecutive missed or corrupted serial data packets over the

serial data channel from a feedback device has exceeded the Feedback Data

Loss Factory Limit. The offending feedback channel is encoded in the

associated Fault/Alarm Sub Code. The threshold is set at four misses.

Disable/Coast

F 47

Feedback Device Failure

The feedback device has detected an internal error. Stegmann encoders

return an error code and Tamagawa encoders have an error flag.

Disable/Coast

F 50

Hardware Overtravel Positive

Axis moved beyond the physical travel limits in the positive direction and

activated the Positive Overtravel limit switch.

Decel/Disable

F 51

Hardware Overtravel Negative

Axis moved beyond the physical travel limits in the negative direction and

activated the Negative Overtravel limit switch.

Decel/Disable

F 54

(1)

Excessive Position Error

The Position Error value of the position control loop has exceeded the

configured value for Position Error Tolerance.

Decel/Disable

F 55

(1)

Excessive Velocity Error

The Velocity Error value of the velocity control loop has exceeded the

configured value for Velocity Error Tolerance.

Decel/Disable

F 56

Overtorque Limit

Motor torque has risen above user defined maximum torque level given by

Overtorque Limit.

Decel/Disable

F 57

Undertorque Limit

Motor torque has dropped below user defined minimum torque level given

by Undertorque Limit.

Decel/Disable

F 61

Enable Input Deactivated

Enable has been deactivated while the axis is in Running state.

Decel/Disable

F 62

Controller Initiated Exception

Exception generated specifically by controller.

Disable/Coast

(1) When a TTL encoder loses its A/B signals it is not detected directly. Instead a secondary fault to detect the condition, typically excessive position or velocity error. In this case the motor coasts to a stop, but

is still be enabled in Logix Designer application.

Table 56 - Drive Behavior, F xx Fault Codes (continued)

Four-digit Display

Exception

Description

Best Stopping Method

(only major fault)

IMPORTANT

The fault detection ability of TTL encoders is not as advanced as with Stegmann

hiperface or Tamagawa 17-bit serial encoders. When a TTL encoder loses its A/

B signals, the Kinetix 350 drive is unable to detect this directly. Instead it relies

on a secondary fault to detect the condition, typically excessive position or

velocity error. There are some cases, particularly in Torque mode where the

fault isn't detected at all. In this case the motor coasts to a stop, but is still be

enabled in Logix Designer application.

Table 57 - Drive Behavior, Fcxx Custom Fault Codes

Four-digit Display

Exception

Description

Best Stopping Method

(only Major Fault)

Fc02

Motor Voltage Mismatch

The motor voltage is incompatible with the applied drive voltage.

Disable/Coast

Fc05

Feedback Battery Loss

The battery voltage on a battery-backed motor encoder is low enough such

that absolute position is not longer available. This occurs when the battery

is too low and encoder main power has been removed.

Decel/Disable

Fc06

Feedback Battery Low

The battery voltage on a battery-backed motor encoder is below a caution

level. This occurs when the battery is too low, but main power has not yet

been removed.

Decel/Disable