Motor brake – Rockwell Automation 2097-Vxxx Kinetix 350 Single-axis EtherNet/IP Servo Drive User Manual User Manual

Page 32

32

Rockwell Automation Publication 2097-UM002A-EN-P - December 2013

Chapter 2 Install the Kinetix 350 Drive System

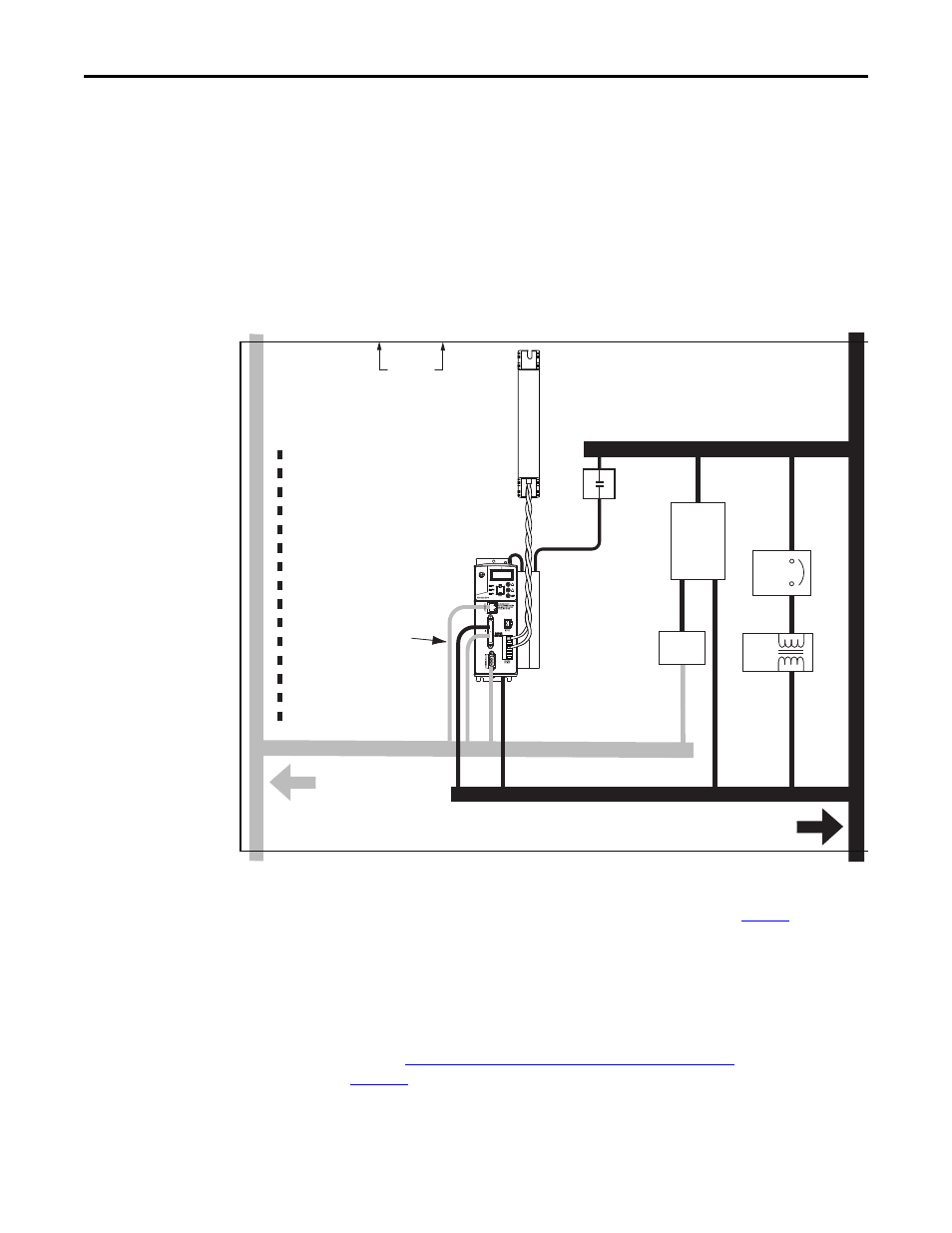

When mounting your shunt module inside the enclosure, follow these additional

guidelines:

• Mount the shunt resistor anywhere in the dirty zone, but as close to the

Kinetix 350 drive as possible.

• Shunt wires can be run with motor power cables.

• Keep unshielded wiring as short as possible. Keep shunt wiring as flat to

the cabinet as possible.

• Separate shunt wires from other sensitive, low-voltage signal cables.

Figure 9 - Shunt Resistor inside the Enclosure

(1) If drive system I/O cable contains (dirty) relay wires, route cable in dirty wire way.

(2) When space does not permit 150 mm (6.0 in.) clearance, install a grounded steel shield between the drive and clean wireway. For

examples, refer to the System Design for Control of Electrical Noise Reference Manual, publicatio

.

Motor Brake

The brake is mounted inside the motor and how you connect to the drive

depends on the motor series.

Kinetix 350 Drive/Rotary Motor Wiring Examples

beginning on

for the interconnect diagram of your drive/motor combination.

Shunt Wiring Methods:

Twisted pair in conduit (first choice).

Shielded twisted pair (second choice).

Twisted pair, two twists per foot (min) (third choice).

Contactor

Dirty Wireway

Very dirty zone

segregated (not in wireway).

Ethernet

(shielded)

Cable

No sensitive

equipment within 150

mm (6.0 in.).

(2)

Route 24V DC I/O

Shielded Cable

24V Motor

Brake PS

Circuit

Breaker

I/O

(1)

, Ethernet, and Feedback

Cables

DC

Filter

Kinetix 350

Drive

Route Encoder/Analog/Registration

Shielded Cables

D

VD

C

I/O

(1)

, Motor Power, and Safety Cables

XFMR

D

D

AC Line

Filter

VD

D

C

Clean Wireway

Enclosure