Rockwell Automation 2097-Vxxx Kinetix 350 Single-axis EtherNet/IP Servo Drive User Manual User Manual

Page 135

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

135

Interconnect Diagrams Appendix A

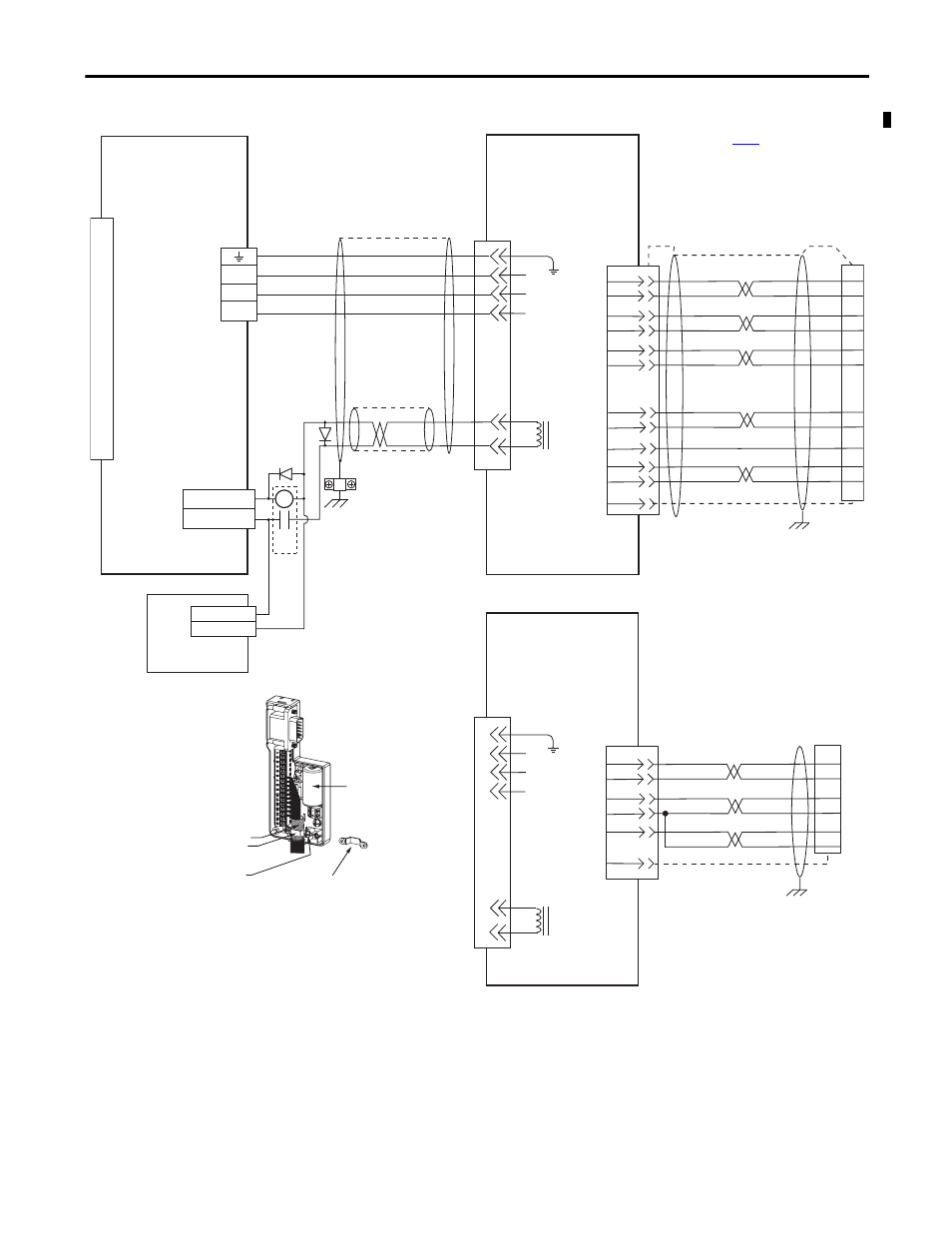

Figure 58 - Kinetix 350 Drive with TL-Series (TLY-A) Motors

5

3

2

1

BR+

BR-

7

9

W

V

U

GND

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

Green/Yellow

Blue

Black

Brown

Black

White

W

V

U

AM+

AM-

BM+

BM-

IM+

IM-

+5VDC

ECOM

WHT/BLUE

GREEN

WHT/GREEN

GRAY

WHT/GRAY

BLACK

WHT/BLACK

RED

WHT/RED

1

2

3

4

5

10

14

6

12

S1

S2

S3

YELLOW

WHT/YELLOW

13

8

SHIELD

22

23

15

24

17

19

9

10

11

12

13

14

5

3

2

1

BR+

BR-

7

9

W

V

U

+5VDC

ECOM

GRAY

WHT/GRAY

22

23

14

6

24

GND

SHIELD

BAT+

BAT-

ORANGE

WHT/ORANGE

6

BAT+

BAT-

DATA+

DATA-

GREEN

WHT/GREEN

13

14

5

10

CR1

MTR_BRAKE -

MTR_BRAKE +

44

43

24V DC

24V DC COM

Motor Brake

Three-phase

Motor Power

Motor

Feedback

TLY-Axxxx-H (230V)

Servo Motors with

Incremental Feedback

2090-K2CK-D15M

Connector Kit

2090-CFBM6DF-CBAAxx (flying-lead) or

2090-CFBM6DD-CCAAxx (with drive-end connector)

Feedback Cable

I/O (IOD)

Connector

Note 4

Motor Power

(MP) Connector

2097-V3xPRx-LM

Kinetix 350 Drives

Motor Feedback

(MF) Connector

2090-CPBM6DF-16AAxx

Motor Power and Brake Cable

Notes 9, 10

Use 2090-CPWM6DF-16AAxx

cable for non-brake applications.

User Supplied

24V DC

Refer to low-profile connector

illustration (lower left)

for proper grounding technique.

Turn clamp over to hold

small cables secure.

Exposed shield secured

under clamp.

Clamp Screws (2)

Refer to table on

TLY-Axxxx-B (230V)

Servo Motors with

High-Resolution Feedback

Cable Shield

Clamp

Only 3.6V battery (2090-DA-BAT2)

required for use with TLY-Axxxx-B motors

(high-resolution 17-bit encoders).

Clamp

2090-CFBM6DF-CBAAxx (flying-lead) or

2090-CFBM6DD-CCAAxx (with drive-end connector)

Feedback Cable

Note 9

Refer to low-profile connector

illustration (lower left)

for proper grounding technique.

Low Profile Connector

(2090-K2CK-D15M shown)

Grounding Technique for

Feedback Cable Shield