Rockwell Automation 2097-Vxxx Kinetix 350 Single-axis EtherNet/IP Servo Drive User Manual User Manual

Page 138

138

Rockwell Automation Publication 2097-UM002C-EN-P - December 2013

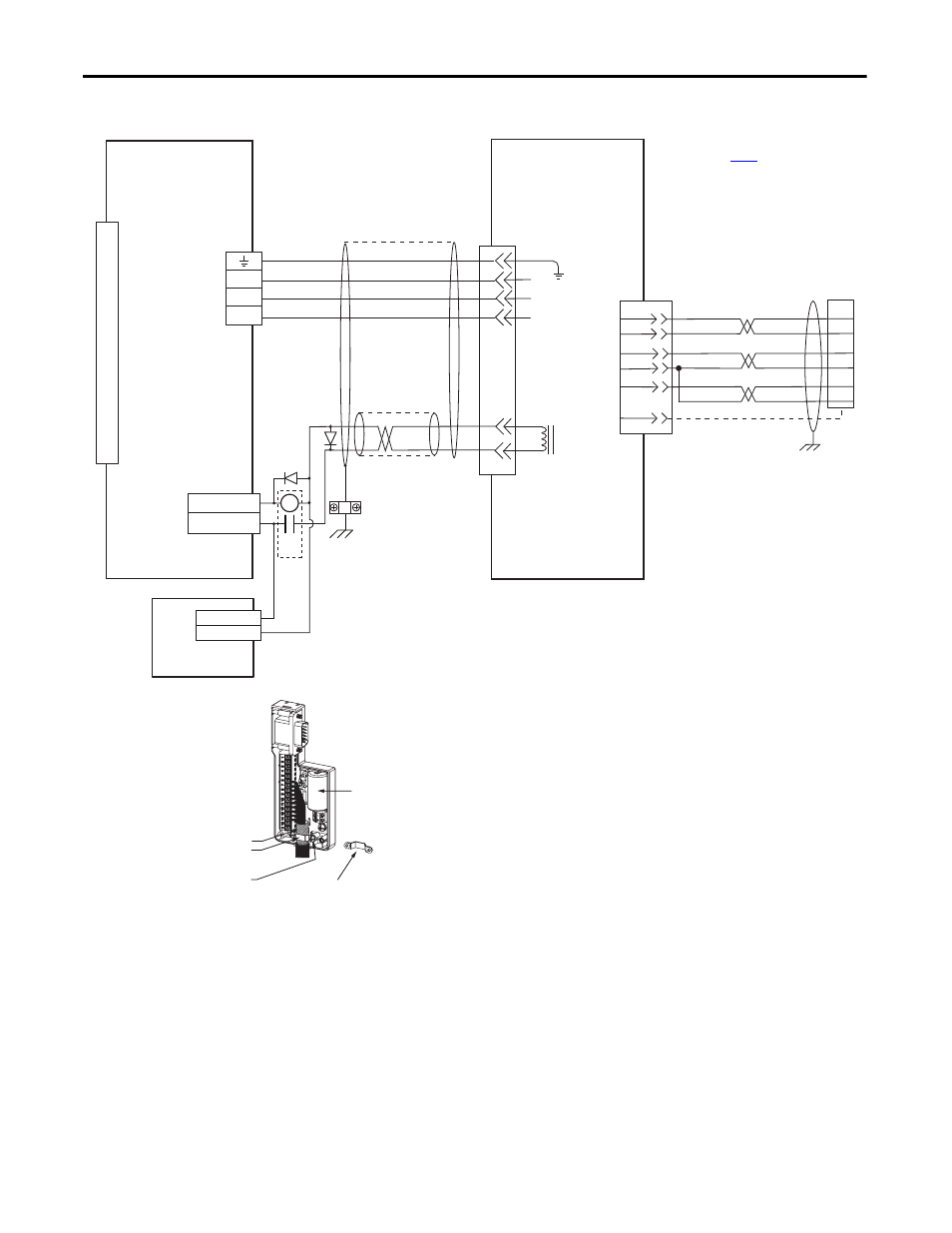

Appendix A Interconnect Diagrams

Figure 61 - Kinetix 350

Drive with TL-Series (Bulletin TLAR) Electric Cylinders

5

3

2

1

BR+

BR-

7

9

W

V

U

GND

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

GREEN/YELLOW

BLUE

BLACK

BROWN

BLACK

WHITE

W

V

U

+5VDC

ECOM

GRAY

WHT/GRAY

22

23

14

6

24

SHIELD

BAT+

BAT-

ORANGE

WHT/ORANGE

6

BAT+

BAT-

DATA+

DATA-

GREEN

WHT/GREEN

13

14

5

10

CR1

MTR_BRAKE -

MTR_BRAKE +

24V DC

24V DC COM

44

43

Motor Brake

Three-phase

Motor Power

Motor

Feedback

TLAR-Axxxxx-B (230V)

Servo Motors with

High Resolution Feedback

2090-K2CK-D15M

Connector Kit

2090-CFBM6DF-CBAAxx (flying-lead) or

2090-CFBM6DD-CCAAxx (with drive-end connector)

Feedback Cable

I/O (IOD)

Connector

Motor Power

(MP) Connector

2097-V3xPRx-LM

Kinetix 350 Drives

Motor Feedback

(MF) Connector

2090-CPBM6DF-16AAxx

Motor Power and Brake Cable

Notes 9, 10

Use 2090-CPWM6DF-16AAxx

cable for non-brake applications.

User Supplied

24V DC

Refer to low-profile connector

illustration (lower left)

for proper grounding technique.

Turn clamp over to hold

small cables secure.

Exposed shield secured

under clamp.

Clamp Screws (2)

Clamp

Refer to table on

3.6V battery (2090-DA-BAT2)

required for use with TLAR-Axxxxx-B electric cylinders

(high-resolution 17-bit encoders).

Cable Shield

Clamp

Low Profile Connector

(2090-K2CK-D15M shown)

Grounding Technique for

Feedback Cable Shield