Watlow EZ-ZONE RMH User Manual

Page 45

Watlow EZ-ZONE

®

RMH Module

•

42

•

Chapter 3 Operations Page

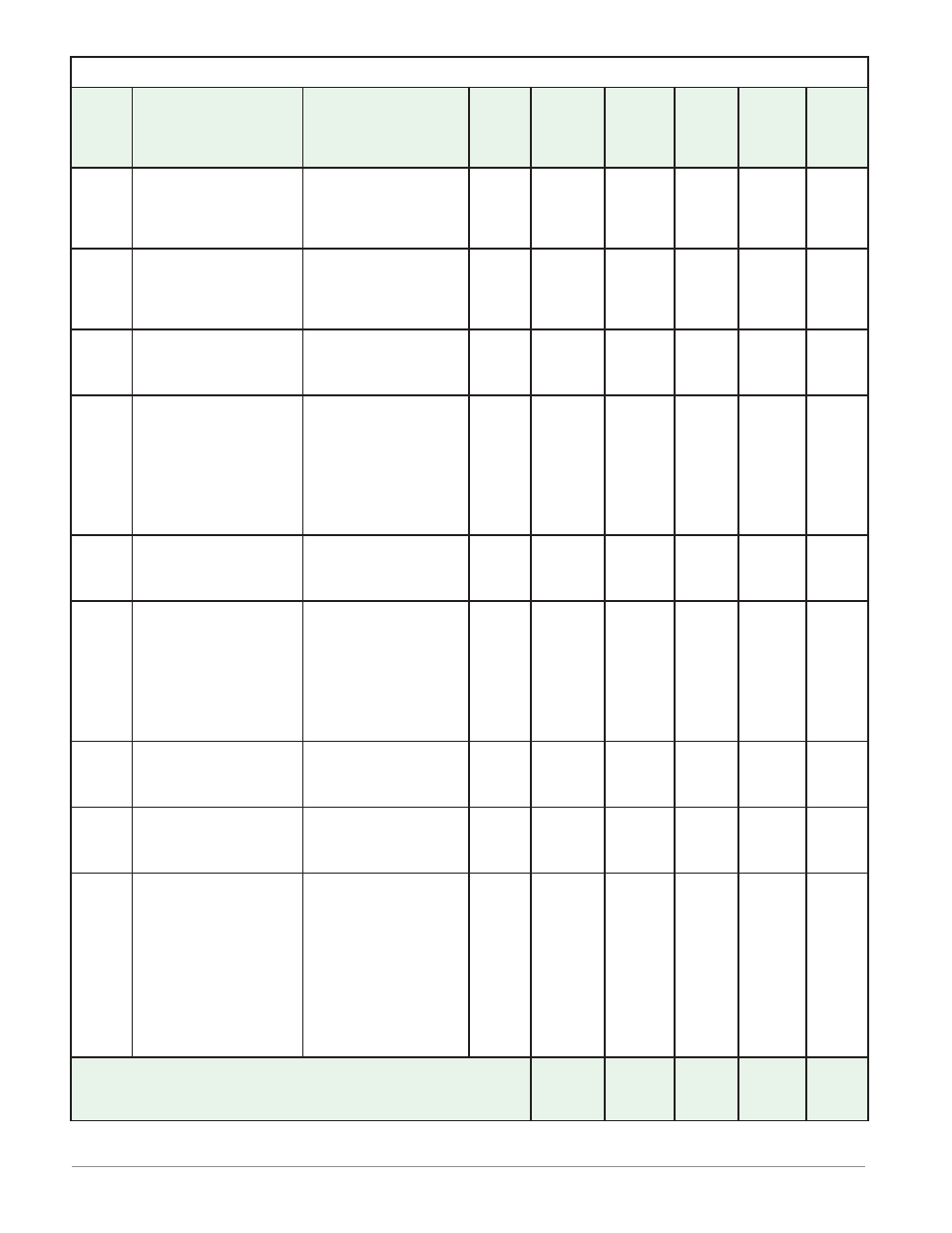

RM High Density Module

•

Operations Page

Display

Parameter Name

Description

Range

Default

Modbus

Relative

Address

CIP

Class

Instance

Attribute

hex (dec)

Profibus

Index

Parameter

ID

Data

Type

& Read/

Write

[`C;SP]

[ C.SP]

Control Loop (1 to 16)

Closed Loop Set Point

Set the set point that the

controller will automati-

cally control to.

Low Set Point to High Set

Point (Setup Page)

75.0°F

or

units

24.0°C

5220

[offset 80]

0x6B

(107)

1 to 16

1

39

7001

float

RWES

[`id;S]

[ id.S]

Control Loop (1 to 16)

Idle Set Point

Set a closed loop set point

that can be triggered by

an event state.

Low Set Point to High Set

Point (Setup Page)

75.0°F

or

units

24.0°C

5236

[offset 80]

0x6B

(107)

1 to 16

9

40

7009

float

RWES

[`h;Pb]

[ h.Pb]

Control Loop (1 to 16)

Heat Proportional Band

Set the PID proportional

band for the heat outputs.

0.001 to 9,999.000°F or

units

0.001 to 5,555.000°C

25.0°F

or

units

14.0°C

4110

[offset 70]

0x97

(151)

1 to 16

6

55

8009

float

RWES

[`h;hy]

[ h.hy]

Control Loop (1 to 16)

Heat Hysteresis

Set the control switching

hysteresis for on-off con-

trol. This determines how

far into the “on” region

the process value needs

to move before the output

turns on.

0.001 to 9,999.000°F or

units

0.001 to 5,555.000°C

3.0°F or

units

2.0°C

4120

[offset 70]

0x97

(151)

1 to 16

0xB (11)

56

8010

float

RWES

[`C;Pb]

[ C.Pb]

Control Loop (1 to 16)

Cool Proportional Band

Set the PID proportional

band for the cool outputs.

0.001 to 9,999.000°F or

units

0.001 to 5,555.000°C

25.0°F

or

units

14.0°C

4112

[offset 70]

0x97

(151)

1 to 16

7

57

8012

float

RWES

[`C;hy]

[ C.hy]

Control Loop (1 to 16)

Cool Hysteresis

Set the control switching

hysteresis for on-off con-

trol. This determines how

far into the “on” region

the process value needs

to move before the output

turns on.

0.001 to 9,999.000°F or

units

0.001 to 5,555.000°C

3.0°F or

units

2.0°C

4122

[offset 70]

0x97

(151)

1 to 16

0xC (12)

58

8013

float

RWES

[``ti]

[ ti]

Control Loop (1 to 16)

Time Integral

Set the PID integral for

the outputs.

0 to 9,999 seconds per

repeat

180 sec-

onds

per

repeat

4114

[offset 70]

0x97

(151)

1 to 16

8

59

8006

float

RWES

[``td]

[ td]

Control Loop (1 to 16)

Time Derivative

Set the PID derivative

time for the outputs.

0 to 9,999 seconds

0 seconds 4116

[offset 70]

0x97

(151)

1 to 16

9

60

8007

float

RWES

[``dB]

[ db]

Control Loop (1 to 16)

Dead Band

Set the offset to the

proportional band. With

a negative value, both

heating and cooling out-

puts are active when the

process value is near the

set point. A positive value

keeps heating and cooling

outputs from fighting each

other.

-1,000.0 to 1,000.0°F or

units

-555.556 to 555.556°C

0.0

4118

[offset 70]

0x97

(151)

1 to 16

0xA (10)

61

8008

float

RWES

Note: Some values will be rounded off to fit in the four-character display . Full values

can be read with other interfaces .

If there is only one instance of a menu, no submenus will appear .

R: Read

W: Write

E: EEPROM

S: User Set