Alarms, Single set point ramping, Process and deviation alarms – Watlow EZ-ZONE RMH User Manual

Page 110: Alarm set points, Alarm hysteresis

Watlow EZ-ZONE

®

RMH Module

•

107

•

Chapter 6 Features

50 percent output

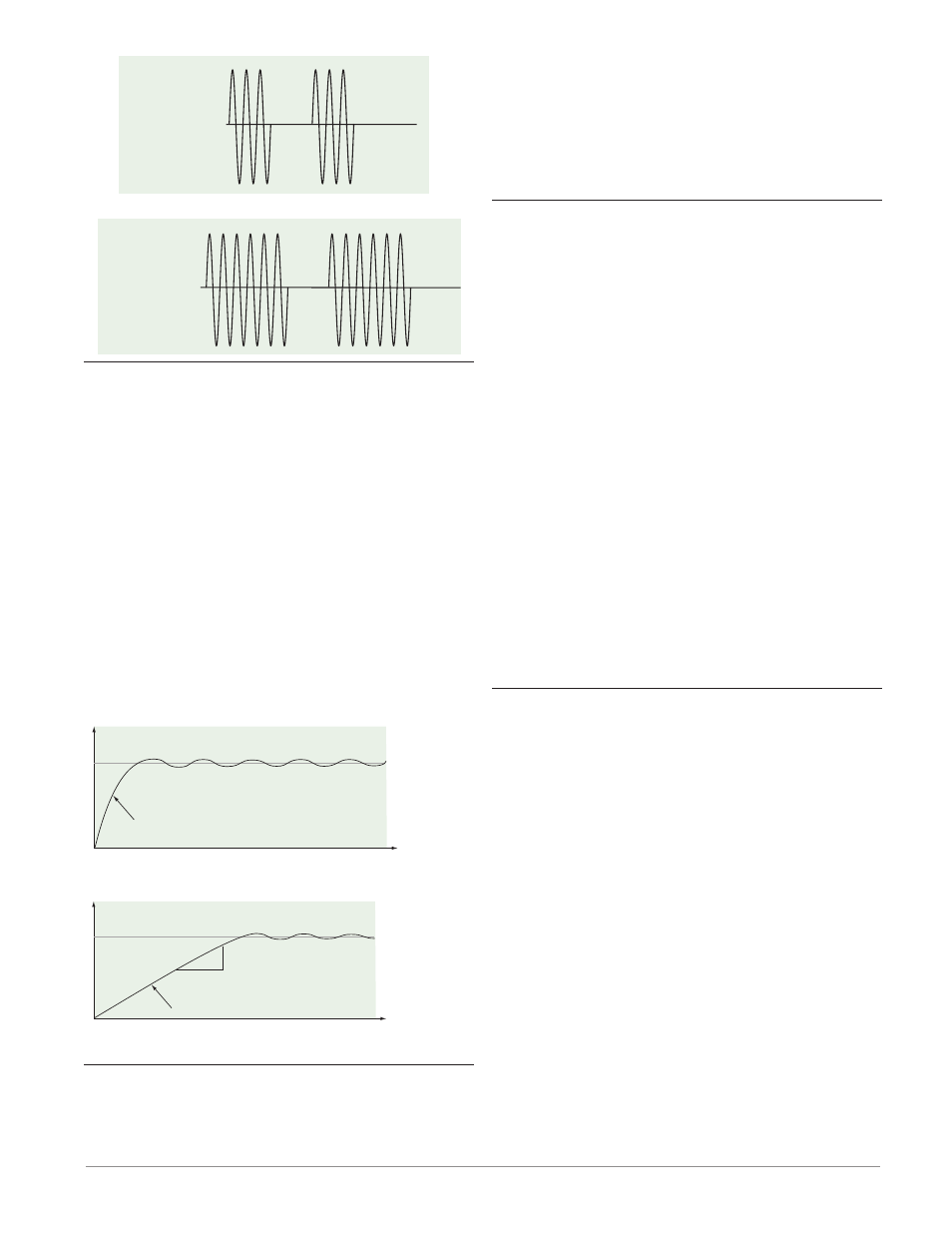

3 ON, 3 OFF

66 percent output

6 ON, 3 OFF

Single Set Point Ramping

Ramping protects materials and systems that can-

not tolerate rapid temperature changes. The value of

the ramp rate is the maximum degrees per minute or

hour that the system temperature can change.

Select Ramp Action [``rP] (Setup Page, Loop

Menu):

[`oFF]

ramping not active.

[`Str]

ramp at startup.

[StPt]

ramp at a set point change.

[both]

ramp at startup or when the set point

changes.

Select whether the rate is in degrees per minute or

degrees per hour with Ramp Scale [`r;SC]. Set the

ramping rate with Ramp Rate [`r;rt] (Setup Page,

Loop Menu).

Set Point

Time

Temperature

Heating System without Ramping

Temperature reaches Set Point quickly

Set Point

Time

Temperature

Heating System with Ramping

Temperature ramps to Set Point at a set rate

degrees

per minute

Alarms

Alarms are activated when the output level, process

value or temperature leaves a defined range. A user

can configure how and when an alarm is triggered,

what action it takes and whether it turns off auto-

matically when the alarm condition is over.

Configure alarm outputs in the Setup Page before

setting alarm set points.

Alarms do not have to be assigned to an output.

Alarms can be monitored and controlled through the

front panel or by using software.

Process and Deviation Alarms

A process alarm uses one or two absolute set points

to define an alarm condition.

A deviation alarm uses one or two set points that

are defined relative to the control set point. High

and low alarm set points are calculated by adding or

subtracting offset values from the control set point.

If the set point changes, the window defined by the

alarm set points automatically moves with it.

Select the alarm type with Type [`A;ty] (Setup

Page, Alarm Menu).

Alarm Set Points

The alarm high set point defines the process value

or temperature that will trigger a high side alarm.

The alarm low set point defines the temperature that

will trigger a low side alarm. For deviation alarms,

a negative set point represents a value below closed

loop set point. A positive set point represents a value

above closed loop set point. View or change alarm

set points with Low Set Point [`A;Lo] and High Set

Point [`A;hi] (Operations Page, Alarm Menu).

Alarm Hysteresis

An alarm state is triggered when the process value

reaches the alarm high or alarm low set point. Alarm

hysteresis defines how far the process must return

into the normal operating range before the alarm can

be cleared.

Alarm hysteresis is a zone inside each alarm set

point. This zone is defined by adding the hysteresis

value to the alarm low set point or subtracting the

hysteresis value from the alarm high set point. View

or change alarm hysteresis with Hysteresis [`A;hy]

(Setup Page, Alarm Menu).