Open loop detection, Alarm latching, Alarm silencing – Watlow EZ-ZONE RMH User Manual

Page 111: Alarm blocking, Lockout menu, Using lockout to hide pages and menus

Watlow EZ-ZONE

®

RMH Module

•

108

•

Chapter 6 Features

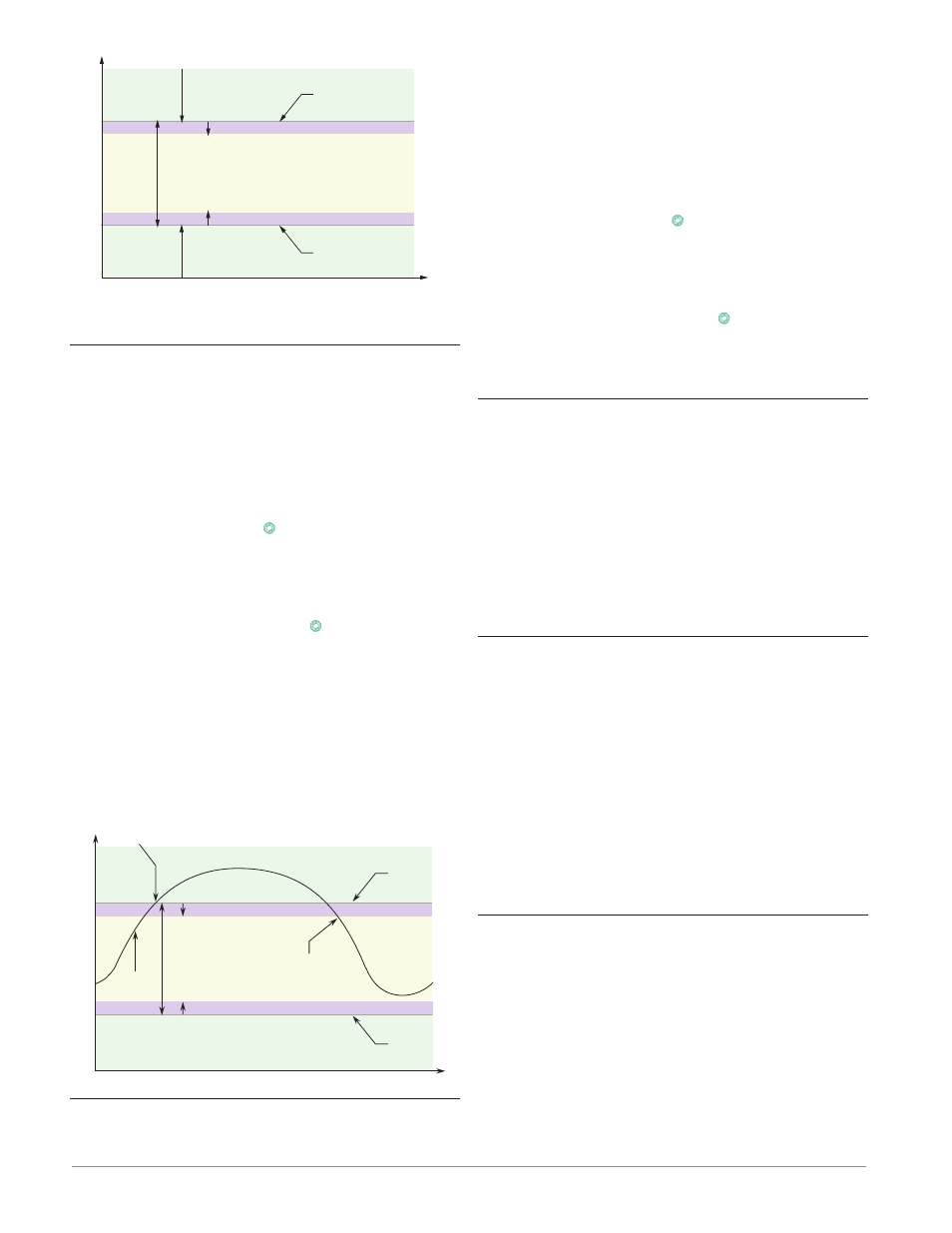

Normal Operating Range

Low Side Alarm Range

High Side Alarm Range

Alarm High Set Point

Alarm Low Set Point

Time

Temperature

Alarm Set Points and Hysteresis

Alarm Hysteresis

Alarm Hysteresis

Alarm Latching

A latched alarm will remain active after the alarm

condition has passed. It can only be deactivated by

the user.

An active message, such as an alarm message,

will cause the RUI display to toggle between the nor-

mal settings and the active message in the upper dis-

play and [Attn] in the lower display.

Push the Advance Key

‰

to display [ignr] in the

upper display and the message source in the lower

display.

Use the Up ¿ or Down ¯ keys to scroll through

possible responses, such as Clear [`CLr] or Silence

[`SiL]

. Then push the Advance

‰

or Infinity ˆ key

to execute the action.

See the Keys and Displays chapter and the Home

Page chapter for more details.

An alarm that is not latched (self-clearing) will

deactivate automatically when the alarm condition

has passed.

Turn alarm latching on or off with Latching

[`A;LA]

(Setup Page, Alarm Menu).

Normal Operating Range

Alarm High

Set Point

Time

Temperature

Alarm Low

Set Point

Alarm Response with Hysteresis

The alarm state continues until the

temperature drops to the Alarm High

Set Point minus the hysteresis. A

latching alarm could be turned off by

the operator at this point. A

non-latching alarm would turn off

automatically.

The alarm state begins when the temperature

reaches the Alarm High Set Point

Process

Temperature

Alarm Hysteresis

Alarm Silencing

If alarm silencing is on the operator can disable the

alarm output while the controller is in an alarm

state. The process value or temperature has to enter

the normal operating range beyond the hysteresis

zone to activate the alarm output function again.

An active message, such as an alarm message,

will cause the display to toggle between the normal

settings and the active message in the upper display

and [Attn] in the lower display.

Push the Advance Key

‰

to display [ignr] in the

upper display and the message source in the lower

display.

Use the Up ¿ and Down ¯ keys to scroll through

possible responses, such as Clear [`CLr] or Silence

[`SiL]

. Then push the Advance

‰

or Infinity ˆ key

to execute the action.

Turn alarm silencing on or off with Silencing

[`A;Si]

(Setup Page, Alarm Menu).

Alarm Blocking

Alarm blocking allows a system to warm up after

it has been started up. With alarm blocking on, an

alarm is not triggered when the process tempera-

ture is initially lower than the alarm low set point

or higher than the alarm high set point. The process

temperature has to enter the normal operating range

beyond the hysteresis zone to activate the alarm

function.

Turn alarm blocking on or off with Blocking

[`A;bL]

(Setup Page, Alarm Menu).

Open Loop Detection

When Open Loop Detection is enabled [`l;de] , the

controller will look for the power output to be at

100%. Once there, the control will then begin to mon-

itor the Open Loop Detect Deviation [`l;dd] as it

relates to the value entered for the Open Loop Detect

Time [`l;dt]. If the specified time period expires

and the deviation does not occur, an Open Loop Error

will be triggered. Once the Open Loop Error condi-

tion exists the control mode will go off.

Note:

All prompts identified in this section can be found

in the Loop Menu of the Setup Page.

Using Lockout to Hide Pages and Menus

If unintentional changes to parameter settings might

raise safety concerns or lead to downtime, your can

use the lockout feature to make them more secure.

Each of the menus in the Factory Page and each

of the pages, except the Factory Page, has a security

level assigned to it. You can change the read and

write access to these menus and pages by using the

parameters in the Lockout Menu (Factory Page).

Lockout Menu

There are five parameters in the Lockout Menu (Fac-