Outputs, Linearization, Duplex – Watlow EZ-ZONE RMH User Manual

Page 106: Cool output curve, Retransmitting a process value or set point

Watlow EZ-ZONE

®

RMH Module

•

103

•

Chapter 6 Features

Select the low and high values with Range Low

[`r;Lo]

and Range High [`r;hi] (Setup Page, Analog

Input Menu).

Linearization

The linearization function allows a user to re-linear-

ize a value read from an analog input. There are 10

data points used to compensate for differences be-

tween the sensor value read (input point) and the de-

sired value (output point). Multiple data points enable

compensation for non-linear differences between the

sensor readings and target process values over the

thermal or process system operating range. Sensor

reading differences can be caused by sensor place-

ment, tolerances, an inaccurate sensor or lead resis-

tance.

The user specifies the unit of measurement and

then each data point by entering an input point value

and a corresponding output point value. Each data

point must be incrementally higher than the previous

point. The linerization function will interpolate data

points linearly in between specified data points.

2

3

4

5 6

7

8

9

Reading from Sensor

without Linearization

(Actual Value)

Input Point 1

Output Point 1

Input Point 10

Output Point 10

Offset Zone

Reading from Sensor

with Linearization

(Displayed Value)

No Offset

T

emperature

Time

Outputs

Duplex

Certain systems require that a single process output

control both heating and cooling outputs. An EZ-

ZONE

®

RMH controller with a process output can

function as two separate outputs.

With a 4 to 20mA output the heating output will

operate from 12 to 20mA (0 to +100 percent) and the

cooling output will operate from 12 to 4mA (0 to -100

percent).

In some cases this type of output is required by

the device that the EZ-ZONE RMH controls, such

as a three-way valve that opens one way with a 12

to 20mA signal and opens the other way with a 4 to

12mA signal. This feature reduces the overall system

cost by using a single output to act as two outputs.

Outputs 1 and 3 can be ordered as process out-

puts. Select duplex [dUPL] as the Output Function

[``Fn]

(Setup Page, Output Menu). Set the output to

volts [uoLt] or milliamps [`MA] with Output Type

[`o;ty]

. Set the range of the process output with

Scale Low [`S;Lo] and Scale High [`S;hi].

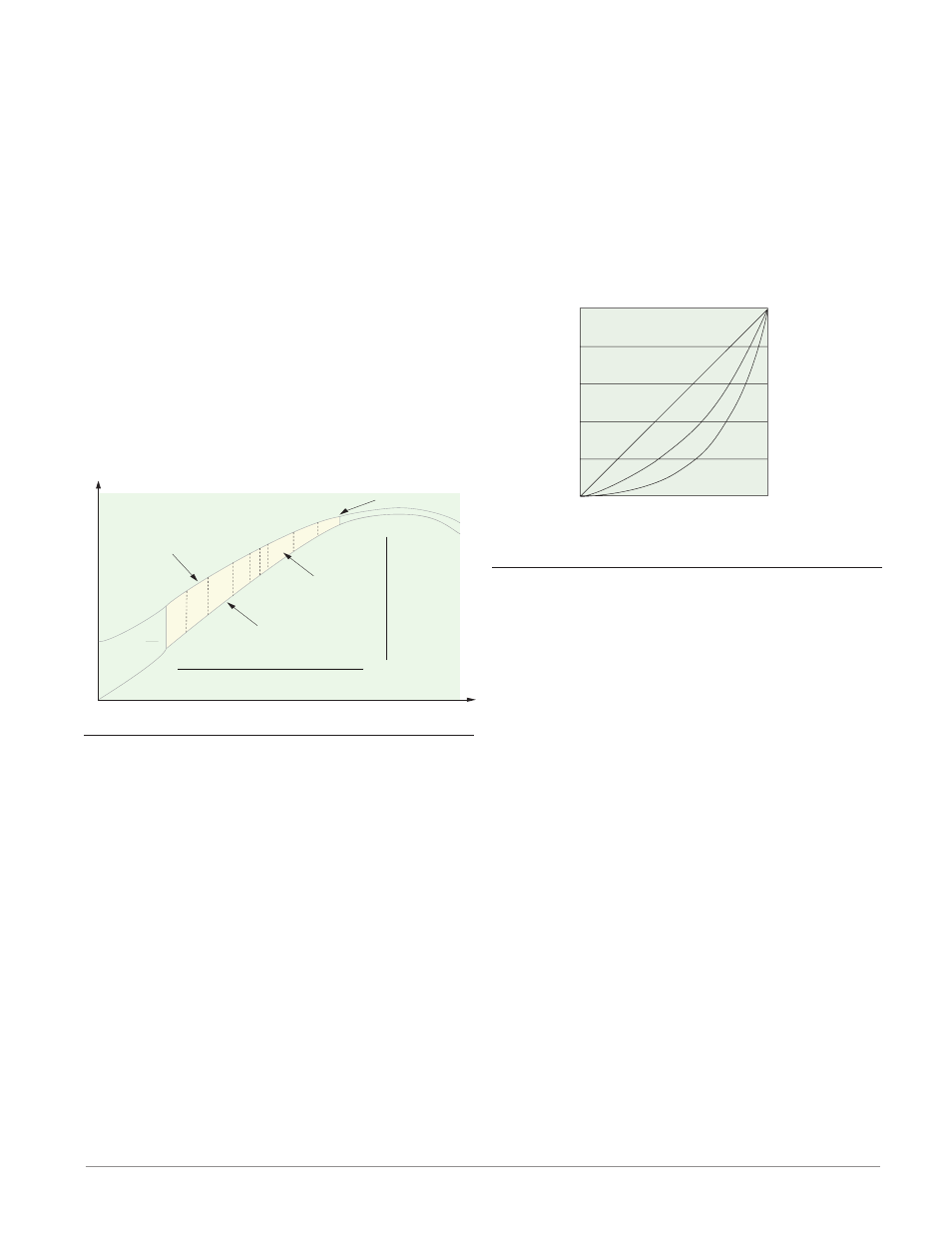

Cool Output Curve

A nonlinear output curve may improve performance

when the response of the output device is nonlinear.

If a cool output uses one of the nonlinear curves a

PID calculation yields a lower actual output level

than a linear output would provide.

These output curves are used in plastics extruder

applications: curve 1 for oil-cooled extruders and

curve 2 for water-cooled extruders.

A

ctual Output

Po

wer

0

20

40

60

80

100

PID Calculation

Linear

Curve 1

Curve 2

Select a nonlinear cool output curve with Cool Out-

put Curve [`C;Cr] (Setup Menu, Loop Menu).

Retransmitting a Process Value or Set Point

The retransmit feature allows a process output to

provide an analog signal that represents the set point

or process value. The signal may serve as a remote

set point for another controller or as an input for a

chart recorder documenting system performance over

time.

In choosing the type of retransmit signal the op-

erator must take into account the input impedance

of the device to be retransmitted to and the required

signal type, either voltage or milliamperes.

Typically, applications might use the retransmit

option to record one of the variables with a chart re-

corder or to generate a set point for other controls in

a multi-zone application.

Outputs 1 to 3 and 7 to 9 can be ordered as pro-

cess outputs. Assign an analog source to Output

Function to accomplish retransmit of a process or set

point value.

Note:

The active set point is not retransmitted, only the

user requested closed loop set point which may not

be the closed loop set point in control. Retransmit-

ting a profiling closed loop set point is not allowed.