IAI America PCON-CFA User Manual

Page 33

2. ACON-C/CG,

PCON-C/CG

25

2.6.3 Position/Simple Direct Mode

In this mode, the actuator is operated by specifying position numbers. You can select whether to set the target

position directly as a value or use a value registered in the position data table, by switching a control signal

(PMOD signal).

For all data other than the target position, such as speed, acceleration/deceleration and positioning band, values

in the controller’s position table are used. Set desired position data by referring to the operation manual for the

controller.

Up to 768 position data points can be set.

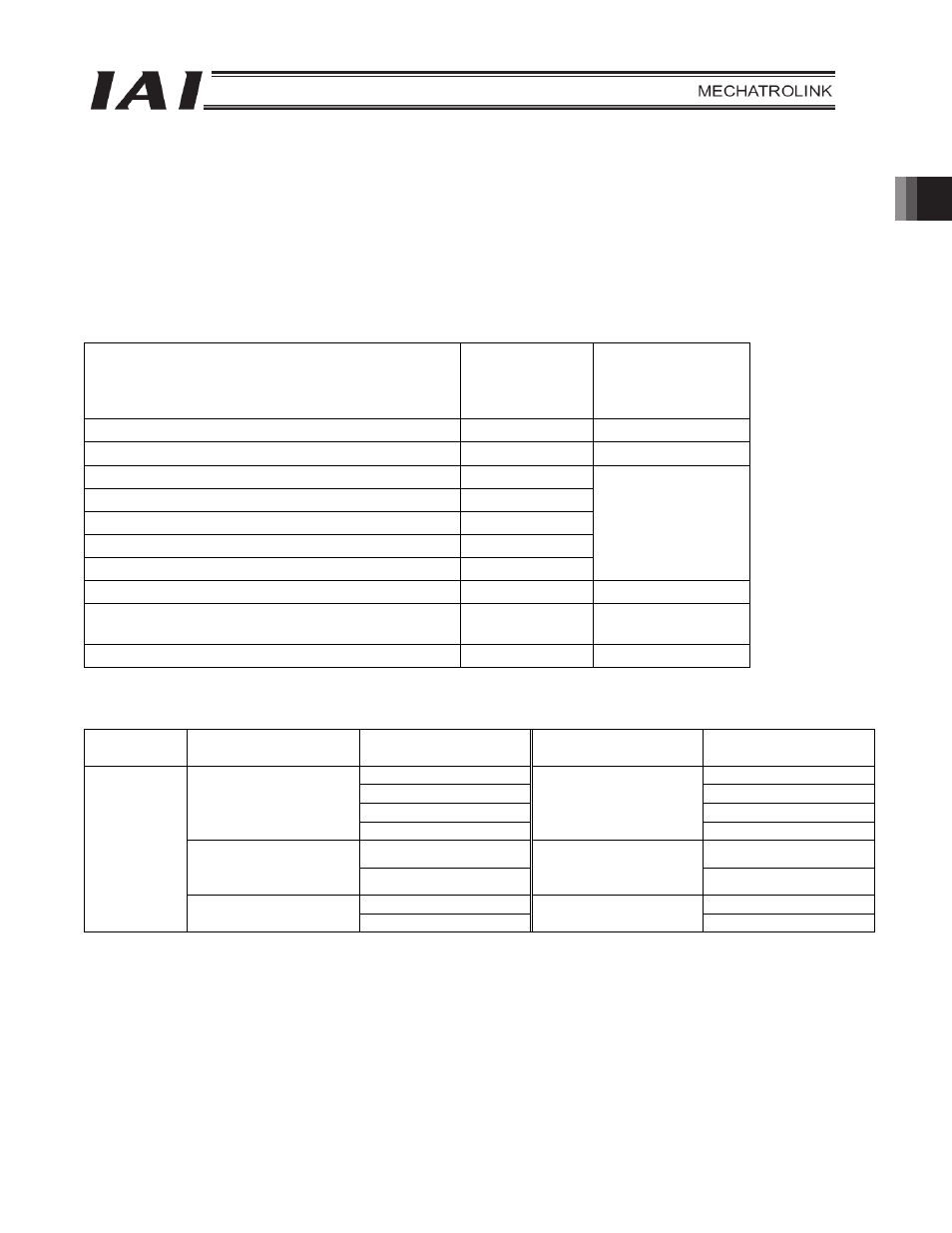

The key functions that are available on ROBO Cylinders controllable in this mode are shown in the table below.

ROBO Cylinder function

{: Direct control

U: Indirect

control

x: Invalid

Remarks

Home return operation

{

Positioning operation

{

Speed & acceleration/deceleration setting

U

Pitch feed (inching)

U

Push-motion operation

U

Speed change during movement

U

Operation at different acceleration and deceleration

U

Position data must

be set

Pause

{

Zone signal output

U

Zones are set using

parameters.

PIO pattern selection

x

(1) PLC address configuration (When the DATA_RWA command is in use)

Parameter

No. 84

ACON/PCON input

register

PLC output address

[

Bytes]

ACON/PCON output

register

PLC input address

[

Bytes]

5 (Lower byte)

5 (Lower byte)

6 (Upper byte)

6 (Upper byte)

7 (Lower byte)

7 (Lower byte)

Target position

8 (Upper byte)

Current position

8 (Upper byte)

9 (Lower byte)

9 (Lower byte)

Specified position

number

10 (Upper byte)

Completed position

number

(simple alarm code)

10 (Upper byte)

11 (Lower byte)

11 (Lower byte)

1

Control signal

12 (Upper byte)

Status signal

12 (Upper byte)

(Note) Pay attention to use of duplicate node addresses.