IAI America IX-NSN6016H User Manual

Page 72

64

7. Specifications

Top

position

Tool

Bottom

position

Tool

Center of

rotational axis

Tool

40

Tool’s center of

gravity

Tool

Center of

rotational axis

φ 100

(Fig. 1)

(Fig. 2)

(Fig. 3)

(Fig. 4)

Item

Specifications

Surrounding air temperature/humidity

Temperature: 0 to 40

°

C, humidity: 20 to 85%RH or less

(non-condensing)

Operating

environment

s

s

e

l

r

o

0

0

0

,

1

m

e

d

u

t

i

t

l

A

B

d

e

s

i

o

N

73

Robot weight

kg

34.5

Air purge pressure (Note 11)

Pressure in a range of 0.05 to 0.6 MPa immediately before

the bellows inflates

Power supply

230 V 50/60 Hz 8 A

Allowable supply voltage

fluctuation

%

±

10

Overvoltage category (IEC

I

I

I

y

r

o

g

e

t

a

C

)

1

-

4

6

6

0

6

Controller

(Note 13)

3

e

e

r

g

e

d

n

o

i

t

u

ll

o

P

)

1

-

4

6

6

0

6

C

E

I

(

e

e

r

g

e

d

n

o

i

t

u

ll

o

P

Note 1)

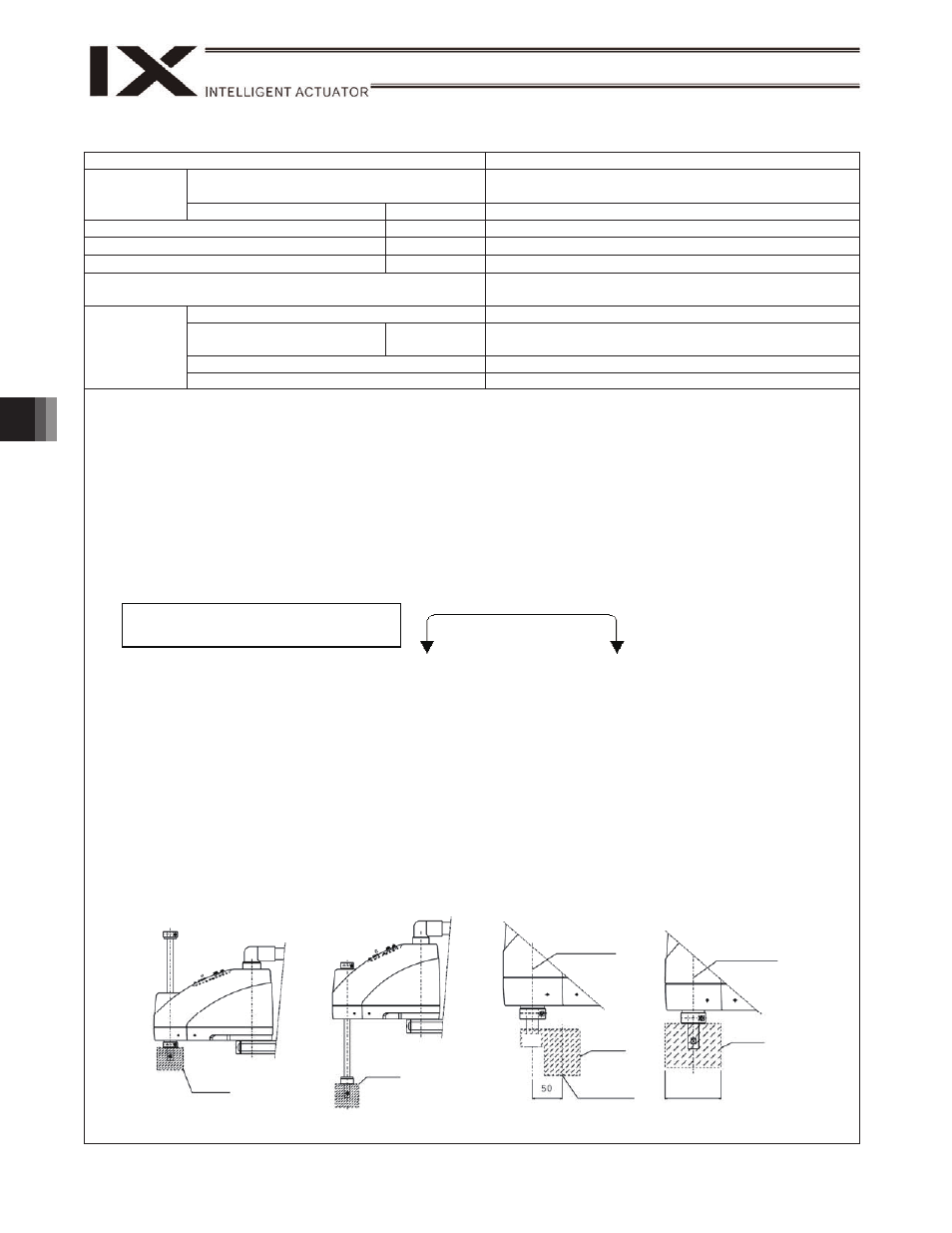

To move the robot horizontally at high speed, perform teaching so that the vertical axis stays as close to the top position as

possible. (Fig. 1)

To operate the robot with its vertical axis at the bottom position, the speed and acceleration must be reduced as appropriate.

(Fig. 2)

Note 2)

Assuming PTP instruction operation. The maximum composite speed is not the maximum speed of CP operation.

Note 3)

Positioning precision when the robot is operated repeatedly to one specified position from the same starting position at the same

speed and acceleration/deceleration using the same arm (at a constant surrounding air temperature of 20

°

C). Take note that this

is not the absolute positioning precision.

Also note that the positioning repeatability may deviate from the specified value if the arm is changed, positioning is performed to

one specified position from multiple positions, or any of the operating conditions such as operating speed and

acceleration/deceleration setting is changed.

Note 4)

Measured when the robot is operated at the maximum speed, carrying a load of 2 kg.

This cycle time assumes a reciprocating operation involving a vertical travel of 25 mm and horizontal travel of 300 mm. (Rough

positioning)

Note 5)

The permissible moment of inertia converted to a value at the rotational center of axis 4. The offset from the rotational center of

axis 4 to the tool’s center of gravity is assumed to be 50 mm or less. (Fig. 3)

If the tool’s center of gravity is further away from the rotational center of axis 4, the speed and acceleration must be reduced as

appropriate.

Note 6)

If the tool exceeds the permissible diameter, it will contact the robot inside the robot’s range of movement. (Fig. 4)

Note 7)

To enable the alarm LED indicator, the user must provide a circuit that supplies 24 VDC to the LED terminal in the user connector

in response to the controller I/O output signal, etc.

Note 8)

Push force when driver card parameter No. 38, “Push torque limit during positioning” is set to 70%.

Note 9)

Push force when driver card parameter No. 38, “Push torque limit during positioning” is set to 20%.

Although this parameter can be set to a desired value from 15 to 70%, push force will not stabilize if the set value is outside the

range of 40 to 70%.

Note 10) Connector pins 1 to 23 can be used. Pin 24 is connected to a shield wire and cannot be used as a signal wire.

Note 11) Increase the pressure to a level within a range of 0.05 to 0.6 MPa until immediately before the bellows inflates, and adjust the

flow rate using the speed controller. The fluid used should be clean, dry air free from compressor oil, etc., and the air filtration

rating should be 10

μm or less.

Note 12) The dust-proof/splash-proof specification is based on a dust-proof/splash-proof structure corresponding to protection class IP65

against intrusion of water and powder dust as specified by the IEC standard. The structure is not explosion-proof.

Note 13) The controller structure is not dust-proof or splash-proof.

Reference design standards: Annex I to Machine Directives, EN292-1, EN292-2, EN1050, EN60204-1, EN775

Note: Continuous operation at the

maximum speed is not feasible.

25 mm

300 mm

Brake power source for main unit

W

DC24VI10% 20W