Setting the taper clamp -15, Setting the taper clamp – Controlled Products Systems Group SWINGSMART DC 20 User Manual

Page 37

Gate Bracket and Linkage Arms

Revision E

Installation

1-15

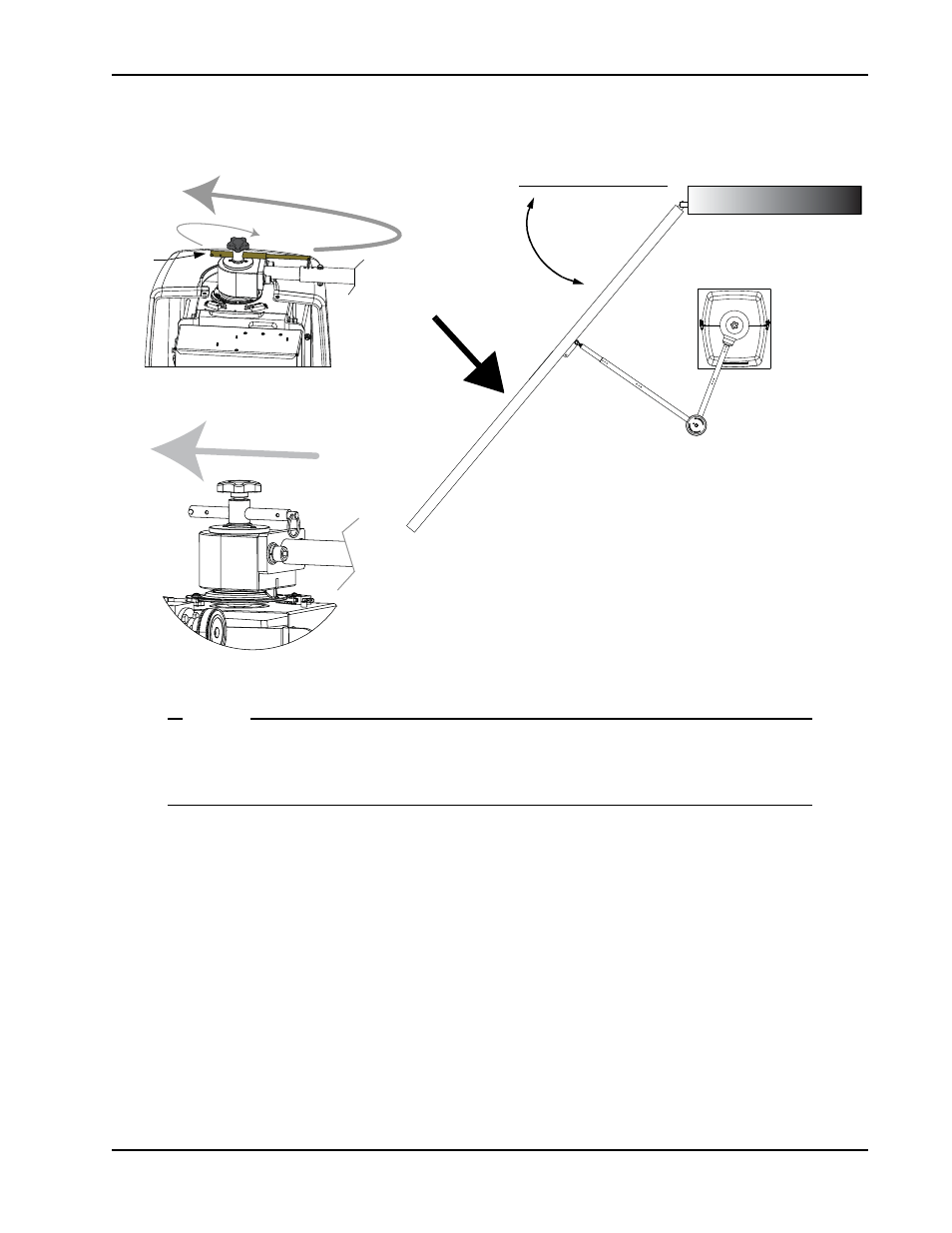

Setting the Taper Clamp

Figure 1-16.

NOTE

Setting the taper clamp with the gate closed impedes traffic flow. If vehicles need to pass

through the gate area, delay setting the taper clamp until after the operator has been configured

to run. Refer to Chapter 3,

The taper clamp is made of two pieces: a cone-shaped hub fits into a taper clamp assembly. The more you turn

the taper handle clockwise the harder it becomes to slip the clutch. In certain situations, such as secure military

facilities, consider straightening the gate arm instead of over-tightening the taper clamp. Refer to

1. To loosen and release the taper clamp, extend the taper handle and turn the handle counterclockwise. See

2. Manually, swing the gate half way between the open and closed position (approximate 45° angle).

3. To tighten the assembly, turn the taper clamp handle clockwise in 1/8-inch (3.2mm) increments. A large

amount of torque is not required in order to obtain a tight clutch setting.

4. Push the gate end with approximately 100 pounds of force to simulate a gate strike. If the taper clamp

slips, use the taper handle to further tighten the assembly.

5. Continue to adjust the taper clamp until no slippage occurs.

6. Retract and center the taper clamp handle.

Tighten

Retract

45° angle

Simulate a gate strike

with ~ 100 lbs. of

force.

Loosen

Taper

handle