Completing gate arm installation -12, Completing gate arm installation, 1a 1b – Controlled Products Systems Group SWINGSMART DC 20 User Manual

Page 34

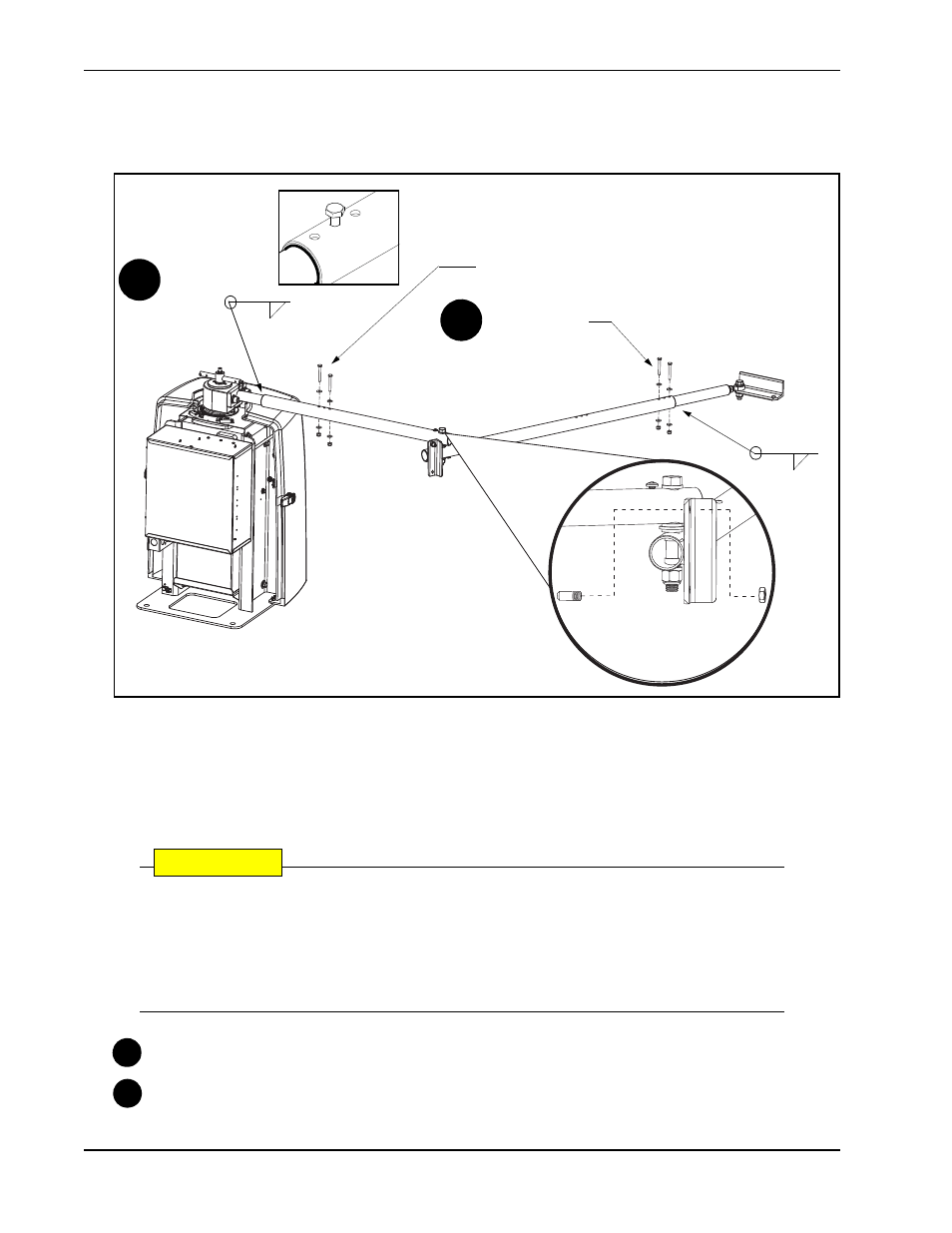

Gate Bracket and Linkage Arms

1-12

SwingSmart DC Installation and Reference Manual

Revision E

Completing Gate Arm Installation

Figure 1-14.

1. To determine whether you should drill & bolt or weld the linkage arms, you should take into consideration

site planning and future impact to gate arm installation. Check whether fire bans exist at your site. Fire bans

do not permit outdoor welding.

2. Paint exposed areas to prevent rusting.

CAUTION

For sites where incident of gate strikes are high, HySecurity recommends setting the elbow with

a slight offset at the full close position. Use the supplied set screw to prevent the arm from lock-

ing. The intent of the offset is that, upon gate strike, the elbow will bend and the taper clamp

will slip, minimizing damage to the gearbox and operator. Be aware if the elbow is set straight

and a gate strike does occur, the full force of the impact will be transferred through the linkage

arms and into the gearbox causing possible damage to the gearbox and operator.

DRILL & BOLT: If you plan to use fasteners, drill holes through the linkage arms. Refer to Figure 1-14.

WELD: If you plan to weld the linkage arms, weld a 1/8-inch fillet around the tubing joint. Only weld at

sites where outdoor welding is permitted.

To weld the linkage arms:

Weld a 1/8-inch fillet

around the tubing joint.

To use fasteners: Drill holes with a 17/64-inch drill bit and connect

arms with 1/4 - 20 UNC fasteners.

1/8"

1/8

"

DRILL & BOLT (2x)

WELD

1A

1B

1A

1B