Drive belt tension and alignment -30, Drive belt tension and alignment – Controlled Products Systems Group SWINGSMART DC 20 User Manual

Page 128

General Maintenance

6-30

SwingSmart DC Installation and Reference Manual

Revision E

D

RIVE

B

ELT

T

ENSION

AND

A

LIGNMENT

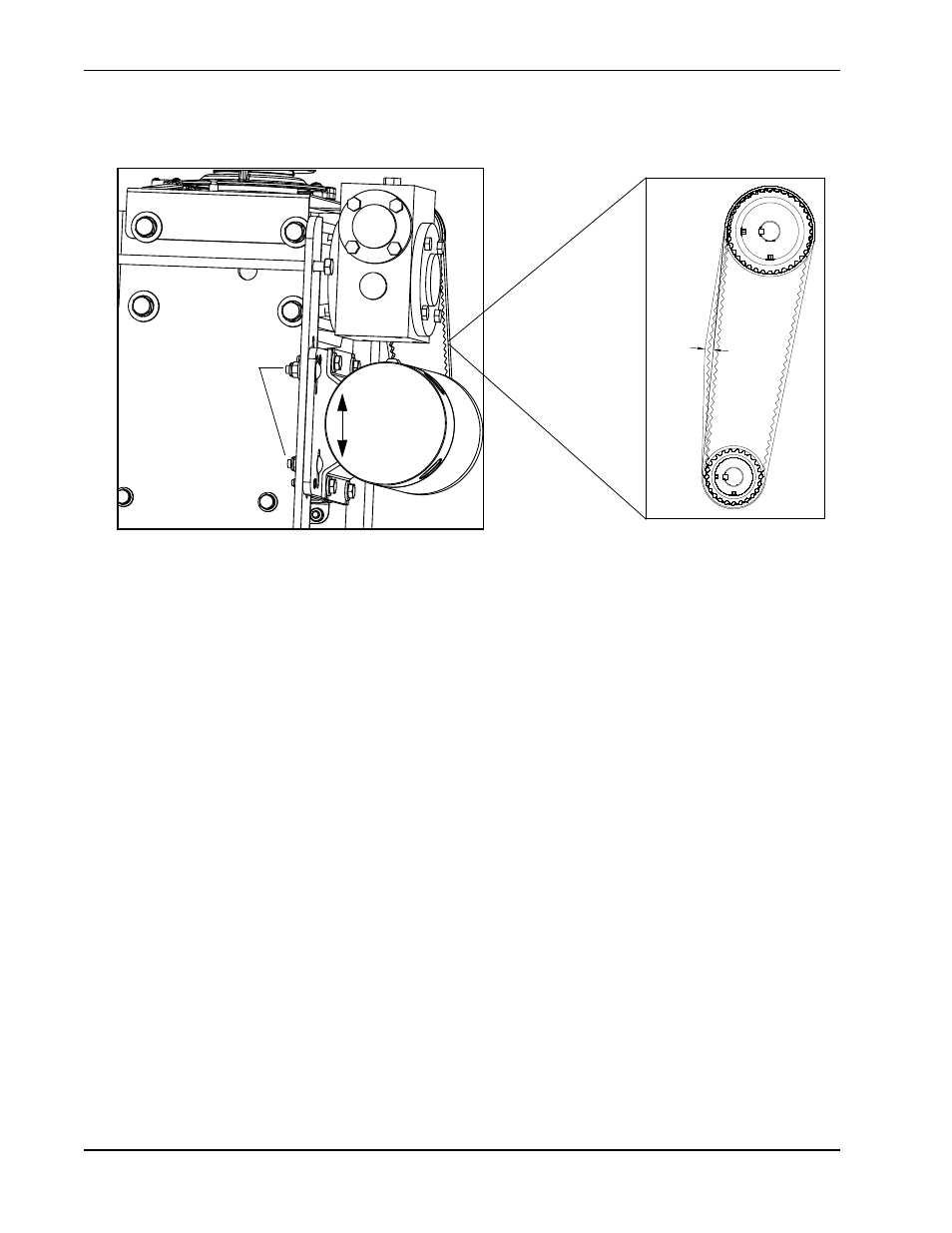

Figure 6-16.

Proper drive belt tension is important for prolonging the life of the drive belt and maintaining the superior

performance of the operator. To check the drive belt tension, take the following steps:

Remove the SwingSmart covers. Refer to

.

1. Turn off the DC and AC power switches.

2. Check to make sure the pulley is aligned vertically.

3. With your finger, apply light outward pressure to the drive belt. If it is properly tensioned, it should only

move about 1/16-inch to 1/8-inch (1.6 to 3.2mm). See Figure 6-16.

4. To replace or re-tension the drive belt. Loosen the two motor bracket bolts and move the bracket

accordingly.

1/16" - 1/8"

loosen 2 fasteners.

To adjust the tension or

replace the belt,

Slide the motor

bracket.

Retighten the

fasteners when

adjustments are

complete.