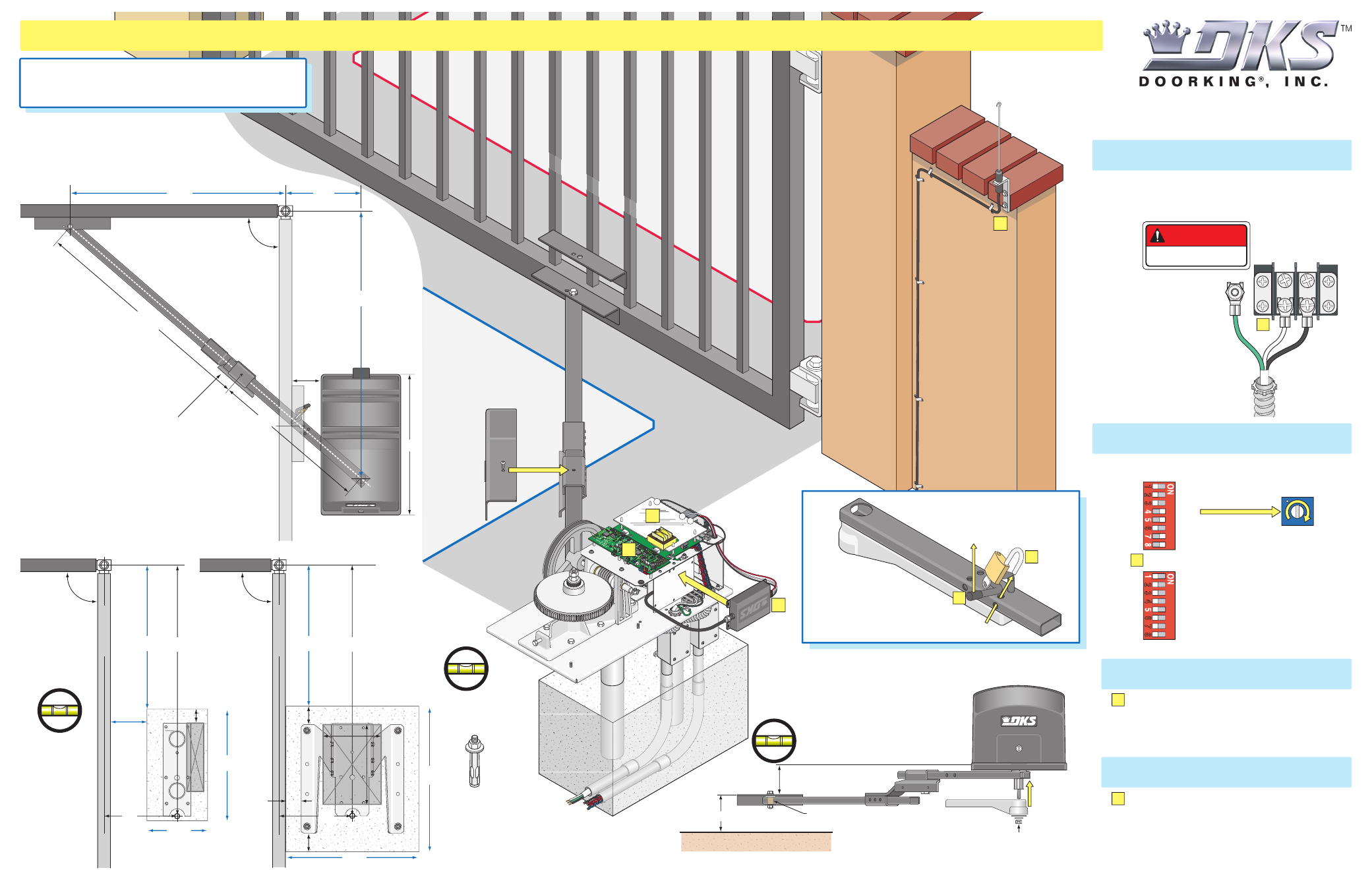

Controlled Products Systems Group 6050-080 User Manual

High voltage connection, Manual release dip-switch settings, Radio receiver loop detectors

Safety

Cover

Shadow Loop

Reverse Loop

vv

Re

Re

Rev

eee

ev

ev

eeve

e e

ssse

LL

eee L

pp

ooop

op

op

oop

Pad Base Gate

Brack

et

Post Base Gate Bracket

22”

High Voltage

Conduit

QUICKSTART “BASIC” GUIDELINES FOR STANDARD MODEL 6050/6100 - FOR GATES UP TO 10 FEET AND OPENING 90°

120 Glasgow Avenue

Inglewood, California 90301

U.S.A.

115 VAC

D

D

High Voltage Connection

Tip:

It is recommended that a surge suppressor

be installed on the high voltage power lines.

GATE OPERATOR MUST BE PROPERLY GROUNDED!!

Copyright 2013 DoorKing, Inc. All rights reserved.

6050-066-E-1-13

Important:

The elbow

assembly must be in the

correct position on the arms

BEFORE cycling operator the

first time.

A

Neutral

115 V

AC

Chassis

Ground

DANGER

HIGH VOLTAGE!

Models 6050/6100 is intended for installation

only on swing gates used for vehicles.

Pedestrians must be supplied with a separate access opening.

For safety and installation instructions, please

refer to the Installation/Owner’s manual.

A

Low

Volt

3/4” with

Sweeps

High

Volt

1. Com to #20

2. Relay to #11

3. 24

Volt

to #7

Elbow

Assembly

Elbow Flange

Loop Conduit

Flexible

Conduit

Depth

of th

e

concrete is

determined by

soil conditions

and local

building codes.

Junction Boxes

AC

Power

Condu

it

90°

Open Gate

Note: 2” thick gate Illustrated.

Note: 2” thick

gate Illustrated.

Closed Gate

23”

4”

Gate Bracket

Output

Shaft

Important:

A straight

line drawn from the

closed gate bracket

through the open

gate bracket MUST

intersect the operator

output shaft.

34”

12”

Important:

Elbow flange MUST be on

the opposite side of the closed gate.

Manually adjust the arms to get the

correct open and closed positions

BEFORE powering up the operator.

Open/Close limits will be automatically

set the first time operator is cycled.

37.5”

24”

Operator Position

Concrete Position

Arm Assembly and

Gate Bracket

Height

Post

Base

Pad

Base

Open Gate

Closed Gate

90°

90°

Run conduit on

the opposite

side of the

open gate for

the post base.

Secure operator

to the concrete

pad with four (4)

3/8” x 3” sleeve

anchors

(not supplied).

Mount the

post base into

the concrete

before

installing the

operator.

Closed Gate

2.5”

3”

3”

2”

Conduit

Right Support Le

g

Left Support Le

g

Open Gate

Bottom

Plate of 6300

Important:

Adjust the locknut on the crank power arm

so that it is snug against the washer, but will still allow

the 30” crank arm to rotate with little force.

30” Crank Arm

60” Connecting Arm

Flange

Crank Power Arm

Elbow Assembly

Brass Bushing

Gate

Bracket

Ground

Arms and Operator MUST be level.

Varies with base used.

5”

Manual Release

DIP-Switch Settings

•

NO AC power.

•

NO DC power (On select models).

Pad MUST

be Level.

Post Base

MUST be Level.

Post

Base

Concrete Pad

Concrete

1

2

Crank Power Arm

Crank Arm

3/8

Using shadow loop and gate opening in direction shown.

SW 1

1. OFF

2. OFF

3. OFF

4. ON

5. ON (Operator Type)

6. OFF

7. ON (Single Operator)

8. ON (Tamper Protect)

1. OFF (Opening Counter-Clockwise)

2. OFF

3. OFF

4. OFF

5. OFF (Normal Reverse Function)

6. OFF

7. OFF

8. OFF

SW 2

Auto Close

Timer

Adjust

1 to 23 sec.

B

Conduit

Crank Power Arm

will remain stationary

during manual gate movement.

43”

24”

24”

26”

6”

12”

43”

43”

12”

10”

18.5”

Output

Shaft

Output

Shaft

Position

14”

10”

(See reverse side)

C

Not included - Refer to the Installation/Owner’s

manual and Loop Information Manual (available

FREE from

www.dkaccess.com

) for more

information on loops and loop detectors.

Radio Receiver

Loop Detectors

D

Not included - Refer to a specific Radio Receiver

Manual (available from

www.dkaccess.com

) for

more information on radio receivers and antenna

installation. (See reverse side for wiring)

C

B

20

11

7