Rockwell Automation 8510 AC Spindle Drive System User Manual User Manual

Page 80

Wiring

Chapter 8

8-76

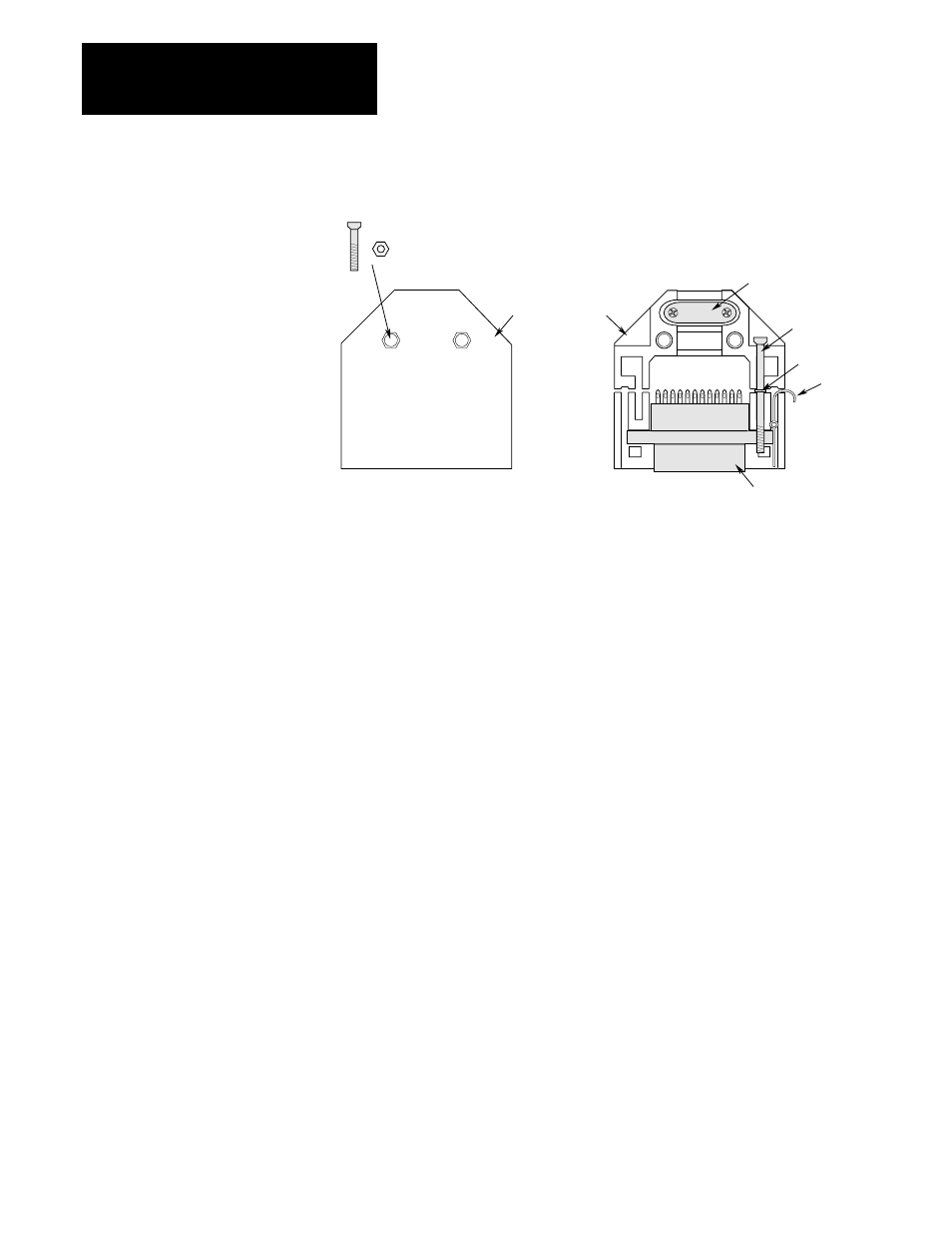

Figure 8.1

Connector Wiring

Cable Clamp

Long Screw

Washer

Clip

Connector Housing

Connector

Short Screw & Nut

Honda Connector Wiring and Assembly

Refer to the following information and the instruction sheet provided with

the connector kit for assembly procedure.

1. Disassemble the connector by removing the 2 short screws and nuts

(see Figure 8.1). Since the connector contains a number of small pieces,

care should be taken during disassembly.

2. Prepare cable and wire ends. Using a rosin core solder, carefully solder

wires to connector using the cable information provided in this chapter.

3. Install cable clamp around cable(s). To allow positioning, do not

tighten clamp completely.

4. Place connector into housing and slide cable clamp to position shown

in Figure 8.1. Tighten cable clamp.

5. Install the 2 long screws and washers through the holes in the

connector. Position screws and washers as shown in Figure 8.1.

6. Place clips into housing and secure remaining housing piece over

assembly using the 2 short screws and nuts previously removed.

The maximum wire size that the terminals in the Honda connector can

accept is 24 AWG (0.28 mm

2

). For each connector, the cable type

recommended in this chapter, or an equivalent, must be used to assure

proper system operation.

If larger wire sizes are preferred, the optional Termination Panels will

allow use of up to 16 AWG (1 mm

2

) wire. If larger cable sizes are used, the

cable configuration and shielding must conform to that specified for the

standard cable.

All shields must be terminated in accordance with the following wiring

diagrams. If one end of a shield is to be left open, take care to insulate and

properly isolate the open end of shield to avoid shorting it to ground.