Jog your machine chapter 5 – Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 69

Enter Your Initial Values Here

Jog Your Machine

Chapter 5

5-8

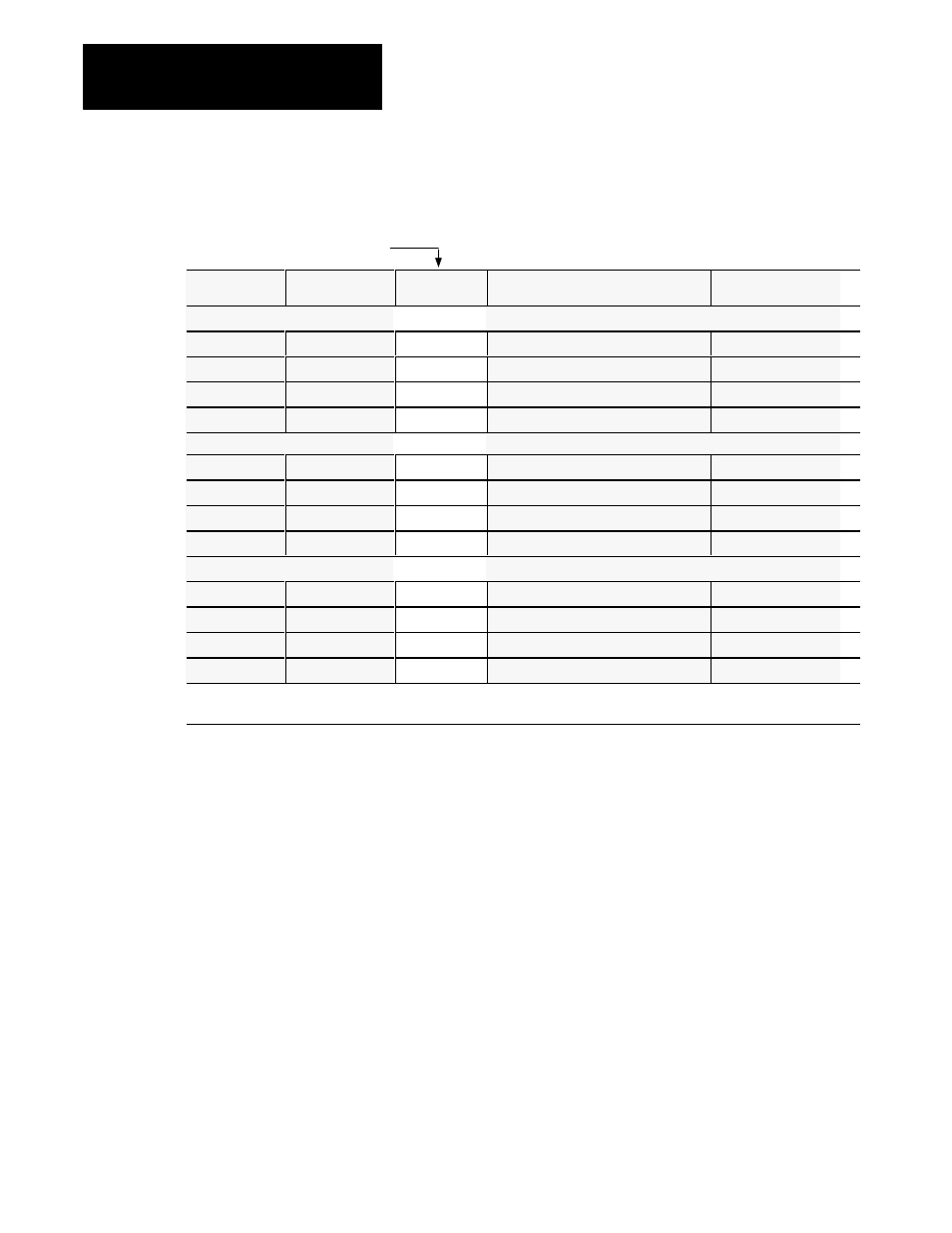

Worksheet 5. B

ScrewĆrotate & Eject Jog Configuration Values for Indirect Control

Control Block

Word

ProĆSet 600 Addr. Value

Description

Units

Screw Rotate Jog

JGC09

N40:65

Set Output Values Output #1

% Signal Output

1

JGC10

N40:66

Output #2

% Signal Output

1

JGC11

N40:67

Output #3

% Signal Output

1

JGC12

N40:68

Output #4

% Signal Output

1

Ejector, Advance Jog

JGC49

N40:105

Set Output Values Output #1

% Signal Output

1

JGC50

N40:106

Output #2

% Signal Output

1

JGC51

N40:107

Output #3

% Signal Output

1

JGC52

N40:108

Output #4

% Signal Output

1

Ejector, Retract Jog

JGC57

N40:113

Set Output Values Output #1

% Signal Output

1

JGC58

N40:114

Output #2

% Signal Output

1

JGC59

N40:115

Output #3

% Signal Output

1

JGC60

N40:116

Output #4

% Signal Output

1

1

% Signal Output

00.00 to 99.99 %

If your hydraulics require it, take time now to develop ladder logic

(independent of Pro-Set 600 software) so the QDC module (in inject and

clamp mode) can assist in screw-rotate and ejector jogs. Otherwise, omit

the rest of this chapter.

Use word 1 in the dynamic command block (DYC01) to enable and disable

individual jogs. Use word 1 in the system status block (SYS01) to monitor

the QDC module’s reaction to jog commands. Tables 5.C and 5.D identify

command and status bits for jogging screw rotation and/or the ejector.

Write Ladder Logic to Assist

with ScrewĆrotate and

Ejector Jogs