Configure the qdc module's i/o chapter 3, Determine values for ram (screw) position sensor – Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 47

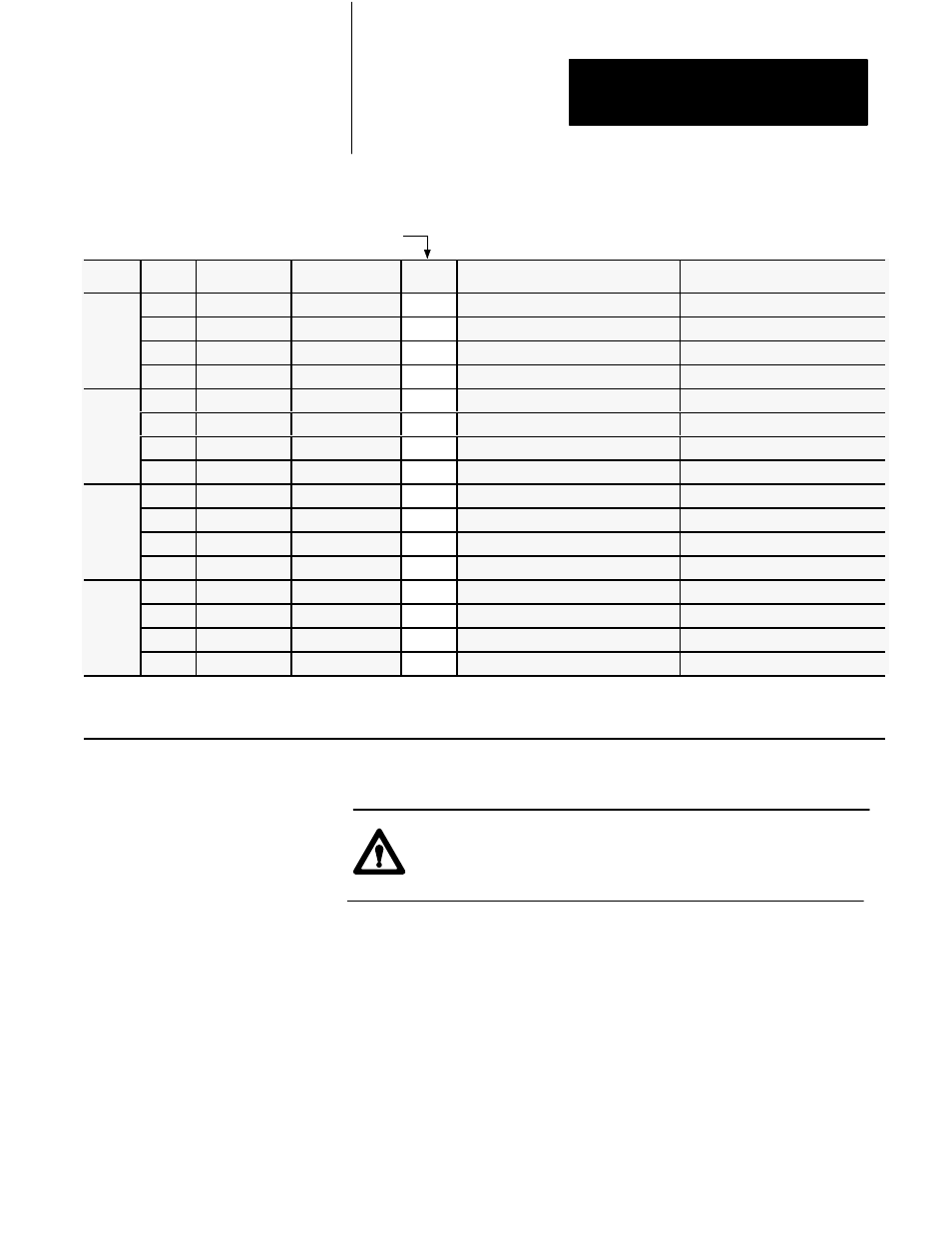

Enter Your Final Values Here

Configure the QDC Module's I/O

Chapter 3

3-9

Worksheet 3ĆE

Final SensorĆconfiguration Values

Input

Line

Control Word

ProĆSet 600 Addr. Value

Description

Units

1

1

MCC09

N40:5

0

Minimum Screw Position

Screw Axis Measured from zero

1

2

MCC10

N40:6

Maximum Screw Position

Screw Axis Measured from zero

1

3

MCC11

N40:7

Analog Signal @ Min Screw Position

Input Signal Range

2

4

MCC12

N40:8

Analog Signal @ Max Screw Position

Input Signal Range

2

2

5

MCC17

N40:13

0

Minimum Screw Pressure

Screw Pressure

3

6

MCC18

N40:14

Maximum Screw Pressure

Screw Pressure

3

7

MCC19

N40:15

Analog Signal @ Min Screw Pressure

Input Signal Range

2

8

MCC20

N40:16

Analog Signal @ Max Screw Pressure

Input Signal Range

2

3

9

MCC23

N40:19

0

Minimum Clamp Position

Clamp Axis Measured from zero

1

10

MCC24

N40:20

Maximum Clamp Position

Clamp Axis Measured from zero

1

11

MCC25

N40:21

Analog Signal @ Min Clamp Position

Input Signal Range

2

12

MCC26

N40:22

Analog Signal @ Max Clamp Position

Input Signal Range

2

4

13

MCC31

N40:27

0

Minimum Clamp Pressure

Clamp Pressure

3

14

MCC32

N40:28

Maximum Clamp Pressure

Clamp Pressure

3

15

MCC33

N40:29

Analog Signal @ Min Clamp Pressure

Input Signal Range

2

16

MCC34

N40:30

Analog Signal @ Max Clamp Pressure

Input Signal Range

2

1

Incremental Distance

2

Input Signal Range

3

Pressure

00.00 to 99.99in

00.00 to 10.00VDC or

0000 to 9999 PSI

000.0 to 999.9mm

01.00 to 05.00VDC or

000.0 to 999.9 Bar

04.00 to 20.00MADC

Determine Values for Ram (Screw) Position Sensor

ATTENTION: Incorrect values entered in DYC09-12 may

result in rapid ram (screw) motion and potential damage to your

barrel and seals of your injection cylinder.

To complete the configuration for your ram (screw) position sensor, do the

following and enter the results on Worksheet 3-E:

Important: If your position sensor has zero and span potentiometers for

setting the zero reference and linear resolution, set them in this procedure.

1.

Move the ram (screw) forward until it reaches its mechanical stop at

the nozzle end. This is the zero position.

2.

Remove ram (screw) pressure and/or flow to stop movement.