Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 14

Overview of Inject and Clamp Mode

Chapter 1

1-2

Clamp Phase:

Description:

1st Close

2nd Close

3rd Close

You can program a singleĆstep clampĆclose profile and not use a second or third profile. Or, you can program up to

three clampĆclose profiles that let you do the following at up to three different points in the clampĆclose phase:

•

pick up a third mold plate

•

set cores

•

pick up or drop out pumps to change clamp speed or pressure

Low Pressure Close

To guard against damaging the mold when the two mold surfaces make contact and to detect obstructions to mold

closure, you close the mold slowly with low pressure and closedĆloop or openĆloop control. Low Pressure Close

can only be controlled through a pressure vs. position profile.

1st Open

2nd Open

3rd Open

You can program a singleĆstep clampĆopen profile and not use a second or third profile. Or, you can program up

to three clampĆopen profiles that let you do the following at up to three different points in the clampĆopen phase:

•

drop out a third mold plate

•

pull cores

•

drop out or pick up pumps to change clamp speed or pressure

Open Slow

To decelerate the moving platen to accurately position it before ejecting the part.

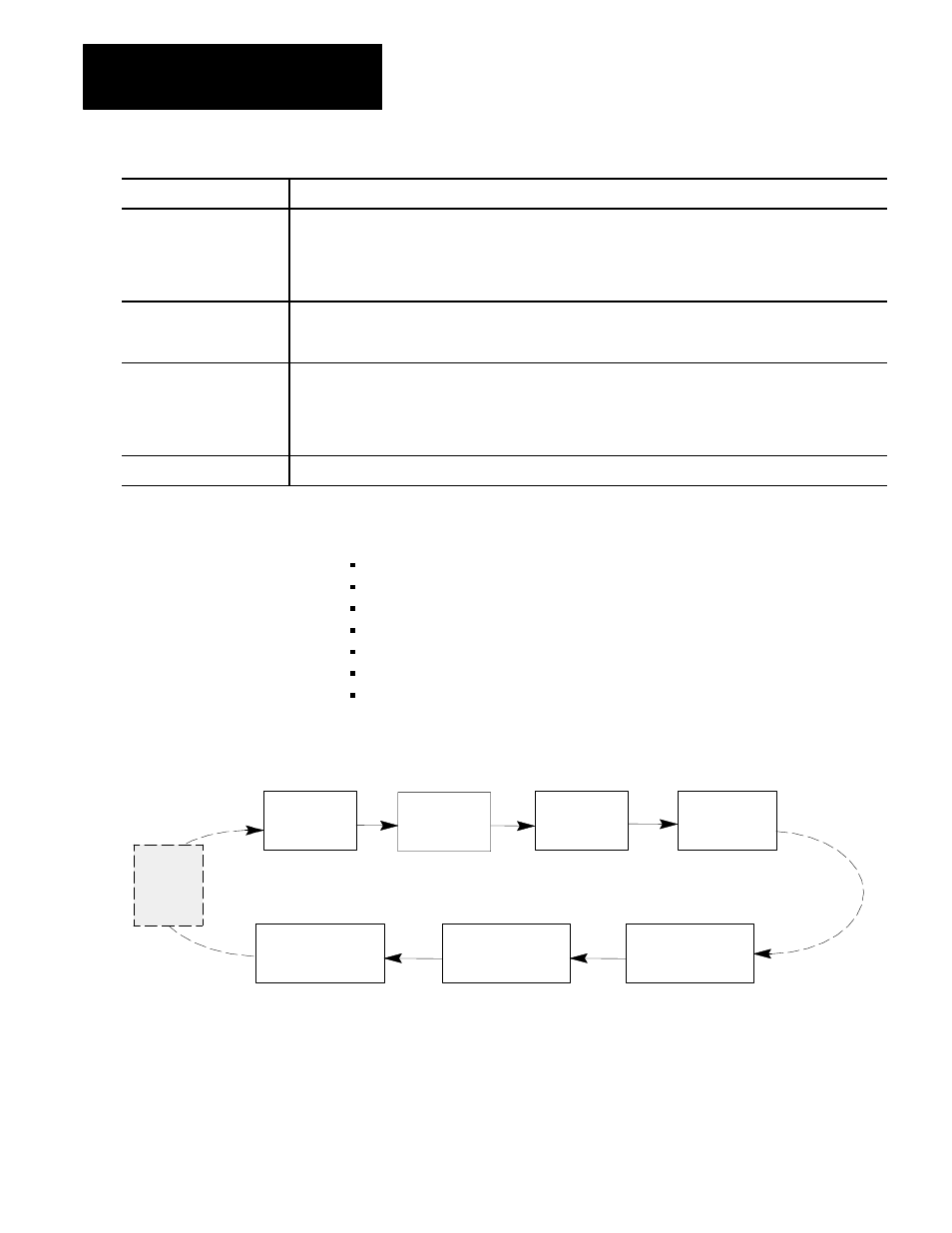

You control inject operation with these phases:

injection

transition

pack

hold

pre-decompression

plastication

post-decompression

Figure 1.1

Inject Operation of a Typical Machine Cycle

Injection

Pack

Hold

Post-

Pre-

Decompression

Decompression

Plastication

(Reload)

Transition to

Pack or Hold

Clamp

& Eject

Operation

Inject Control