Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 23

Overview of Inject and Clamp Mode

Chapter 1

1-11

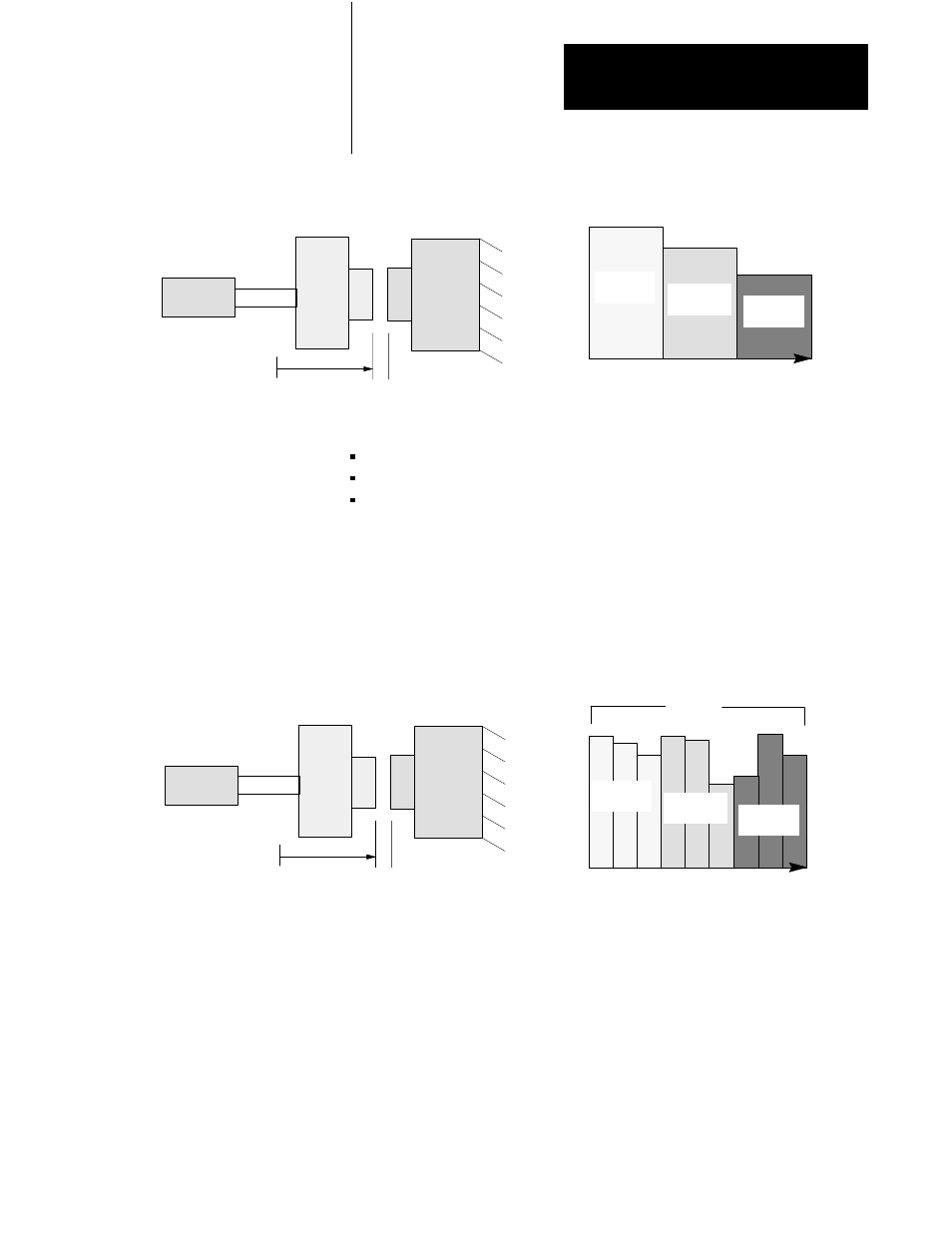

Figure 1.10

Example Clamp Close

L

0

Stationary

Platen

Clamp

Cylinder

Position

Velocity

Moving

Platen

1st Close

Profile

2nd Close

Profile

3rd Close

Profile

X

You may start these operations between the three clamp close profiles:

pick up the 3rd plate of a mold (on a floating 3-plate mold) or set cores

program other events for all valves

automatically bridge between profiles, or let ladder logic decide when to

begin the next profile

Each of the clamp close profiles can be subdivided into three position

segments (Figure 1.11). You can change clamp velocity or pressure up to

three times in each profile, or up to nine times for the entire clamp close

phase.

Figure 1.11

Example Clamp Close Position Segments

Position

Velocity

1st Close

Profile

2nd Close

Profile

3rd Close

Profile

1

1

1

2

2

2

3

3

3

Segments

L

0

Stationary

Platen

Clamp

Cylinder

Moving

Platen

X

Important: You may use as many or as few profiles and/or segments

within profiles as needed for your molding application. If using a single

close fast motion, use the first segment of the 1st close profile. The low

pressure close profile must follow.

After completing the last segment in each profile, the QDC module either

switches immediately to the next programmed segment of the next

programmed profile or waits for a command from your PLC-5 program to

continue.

After completing the last configured close profile, the QDC module either

switches immediately to the first programmed segment of low pressure

close, or waits for a command from your PLC-5 program to continue.