9ć30, Span your pack and hold pressure valves – Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 187

Span Your Valves

Chapter 9

9-30

We recommend that you span your pack and hold pressure valves for

optimum pressure performance in four parts:

Confirm critical values

Span your pack and hold pressure valves

Test valve linearity with a pressure vs. time profile

Set profile pressure alarms

Important: You may omit the next three parts of this section if you have

the right information on valve spanning. Many injection molding machine

OEMs and hydraulic valve manufacturers provide data on spanning the

working range of valves used on their machines. If this information is

available from your OEM for your machine’s pack and hold pressure

valve, enter the values into pressure control limits PKC41-44 for Pack and

HDC41-44 for Hold and proceed to Set Profile Pressure Alarms.

Important: If your machine hydraulics for pack and hold are identical to

those for injection, you may use your injection pressure valve spanning

parameters for pack and hold. If so, enter your values for INC41-44 into

PKC41-44 and into HDC41-44, and skip to Set Profile Pressure Alarms.

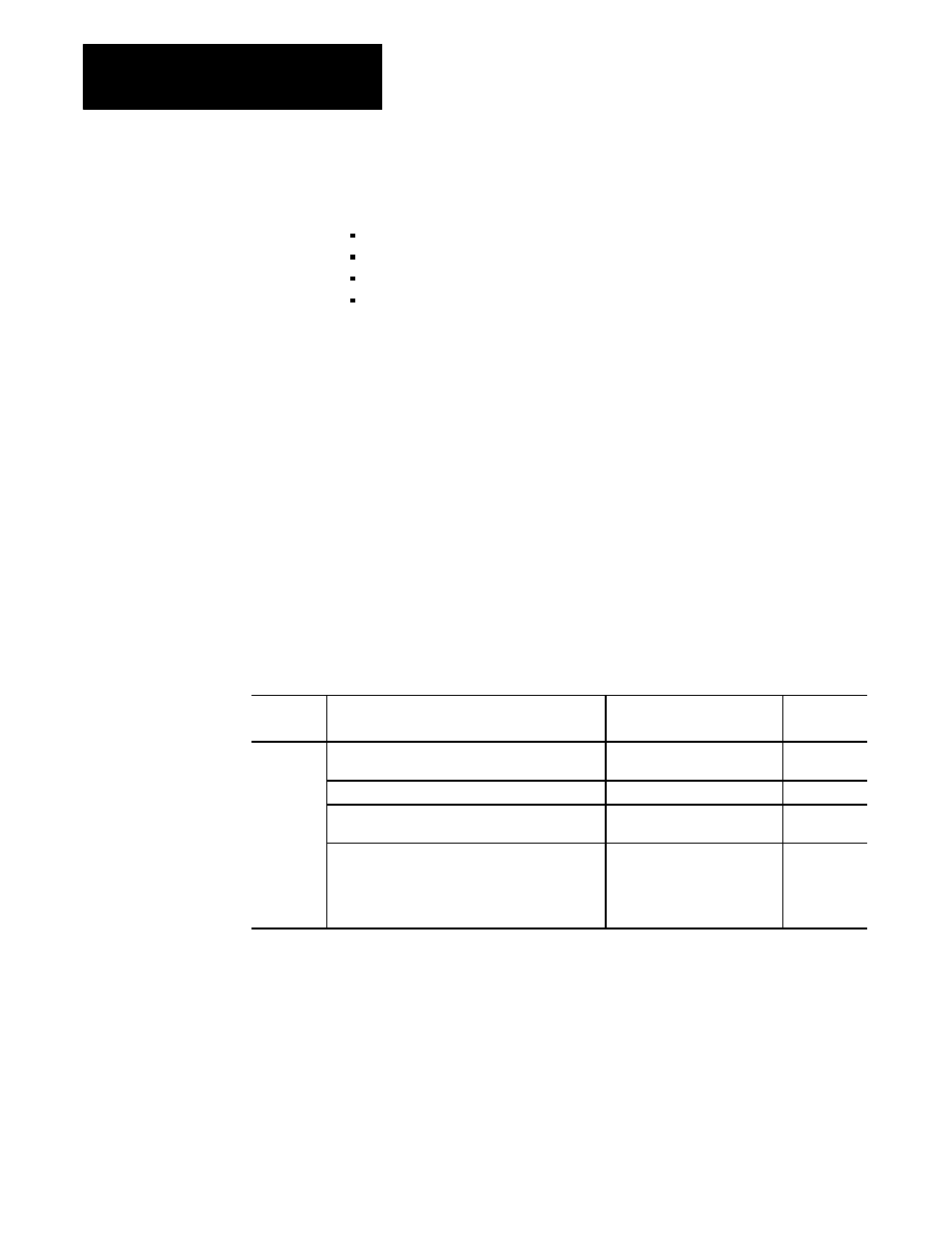

Confirm Critical Values

Important: Confirm that all entries you made for configuration values

(chapter 7) and profile values (chapter 8) are as follows:

On

Worksheet

Confirm Your Configuration

With These Words or Bits

for Pack Pressure

ProĆSet Addr

7ĆF

QDC module output to which you connected your

pressure control valve

PKC02ĆB06, B05, B04

B38/148Ć150

SetĆoutput values for unselected valves

PKC09Ć12 = your values

N44:125Ć128

All ramping is disabled with zero ramp rates

PKC17Ć20 = 0

PKC25Ć28 = 0

N44:133Ć136

N44:141Ć144

Pressure limits:

Minimum Pressure Control Limit

Maximum Pressure Control Limit

Selected Pressure Valve, Output for Minimum

Selected Pressure Valve, Output for Maximum

PKC41 = 0

PKC42 = system pressure

PKC43 = your value

PKC44 = your value

N44:157

N44:158

N44:159

N44:160

Span Your Pack and Hold

Pressure Valves