Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 15

Overview of Inject and Clamp Mode

Chapter 1

1-3

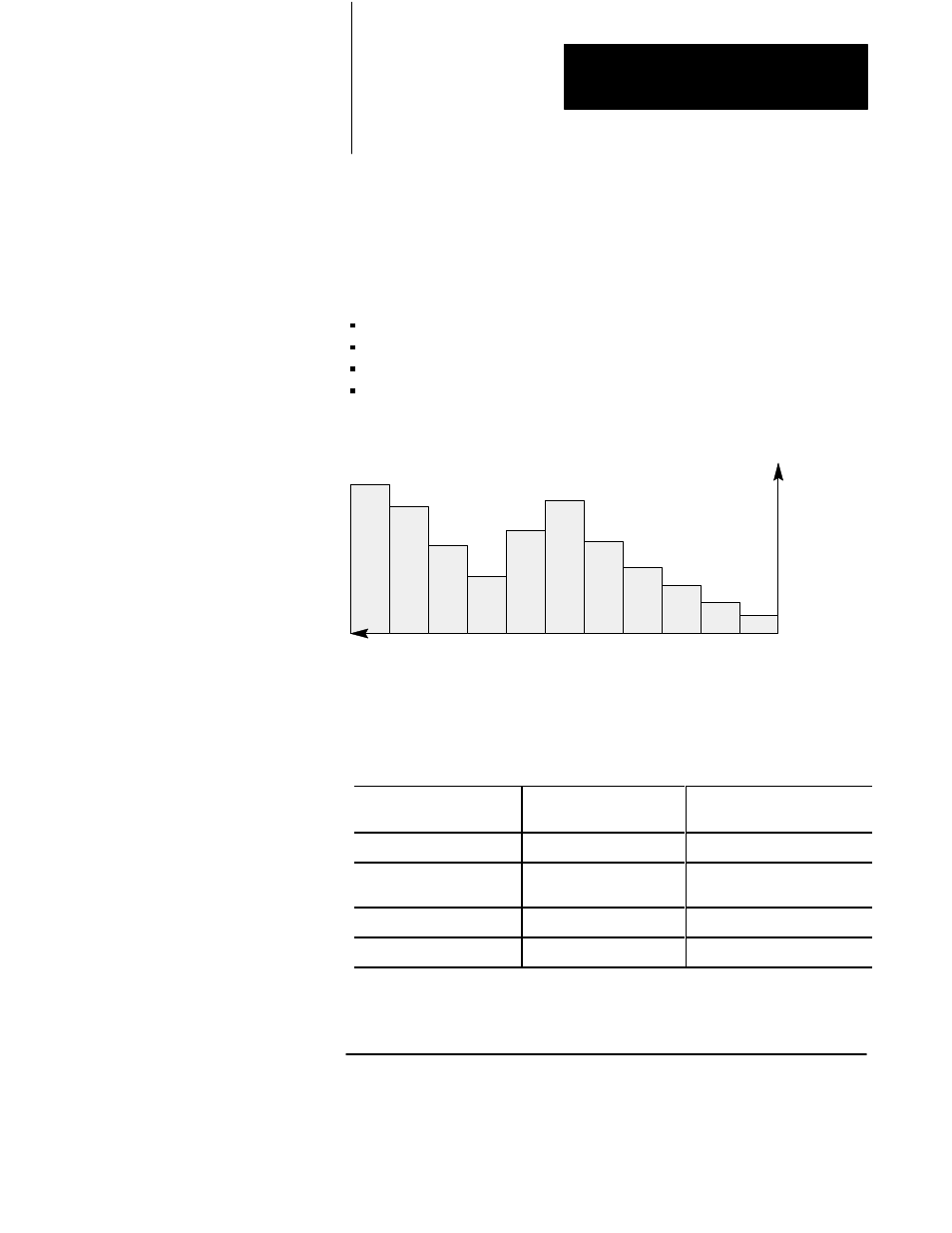

Injection Phase

You can vary the velocity of the ram (screw), or the pressure driving it, so

the leading edge of the melt moves through the mold cavity at the desired

speed. The pattern of velocity or pressure variation during injection is

called the injection profile. The QDC module lets you chose from four

different injection profiles:

velocity vs. position

pressure-limited velocity vs. position

pressure vs. position

pressure vs. time

Figure 1.2

Example Injection Profile

11

10

9

8

7

6

5

4

3

2

1

Position or Time

Velocity or Pressure

You enter setpoints to create a profile. You can select from 1 to 11

segments of position or time. Segment numbers represent the order of

operation. By convention the ram (screw) injects plastic by moving from

right to left.

With this Profile:

You Control Injection:

With up to 11 Segments

Distributed over the:

Velocity vs. Position

Speed

Length of the shot

PressureĆlimited

1

Velocity vs. position

Speed with a

maximum pressure

Length of the shot

Pressure vs. Position

Pressure

Length of the shot

Pressure vs. Time

Pressure

Time for a shot

1

PressureĆlimited velocity vs. position profile differs from the velocity vs. position profile as follows:

During any segment, if the pressure exceeds a preset limit, the module switches to PID pressure

control with the pressure limit as the setpoint. Then if velocity exceeds the velocity setpoint, the

module returns to velocity control.