Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 169

Span Your Valves

Chapter 9

9-12

11.

Lower the set-output value in DYC09-12 corresponding to the

selected clamp close pressure valve to a safe level.

12.

Disable set-output operation. Toggle DYC01-B08 (B34/392) to 0.

13.

Download your changes in FCC, SCC, and TCC to the QDC module.

Important: If downloading from your programming terminal, download

FCC, SCC, TCC, and CPC in that order (chapter 4).

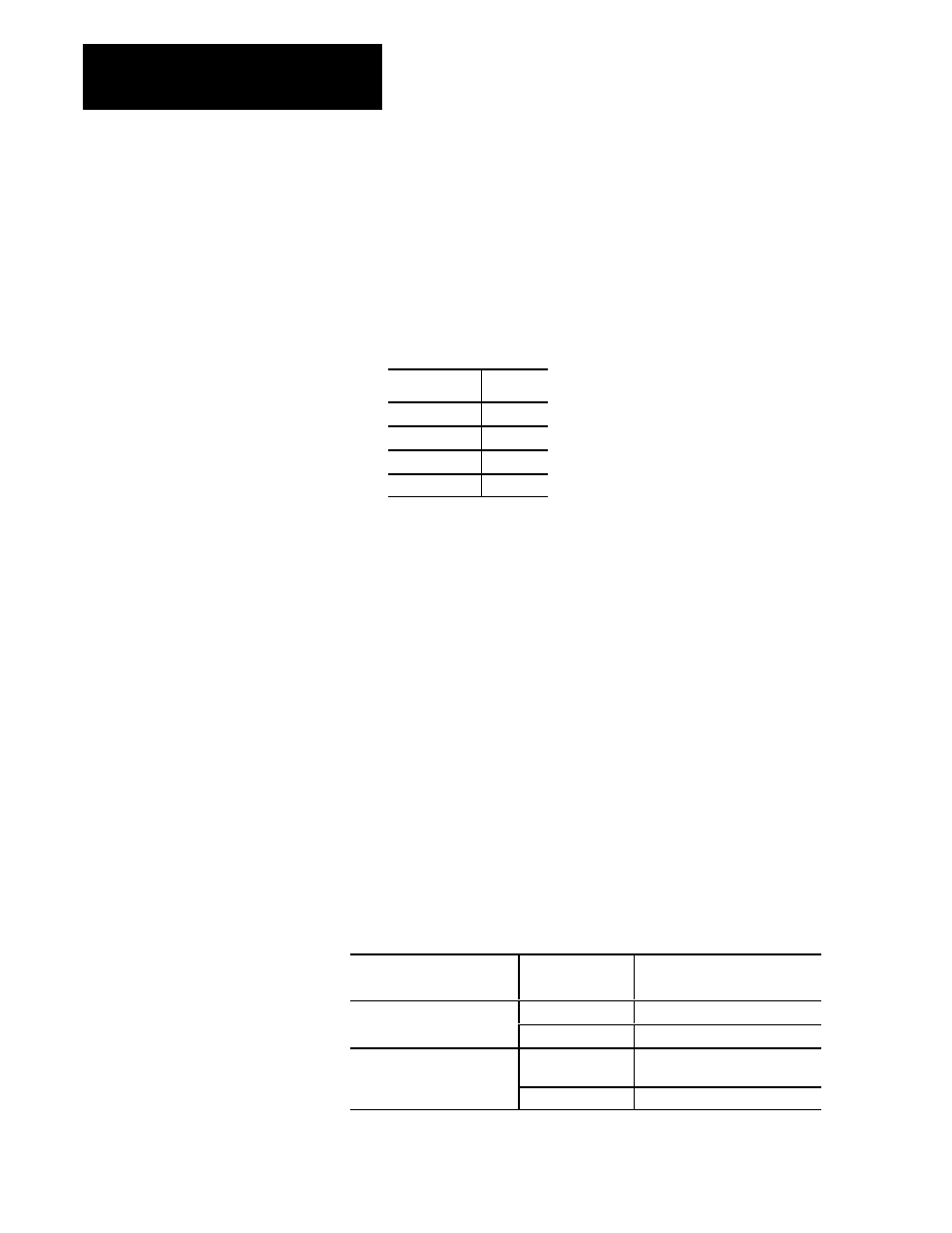

To download

Set B21/

FCC

2

SCC

3

TCC

4

CPC

6

Test Valve Linearity with a Clamp Close Pressure Profile

1.

Jog your clamp to the full open position.

2.

Enable the first clamp close profile by setting DYC02-B00 (B34/400)

to 1. The clamp should move from its start position through clamp

close and low pressure close profiles. If no motion, verify that:

- no clamp overtravel alarms are set. The QDC module inhibits

clamp close if SYS07-B00 through -B05 are set

- no programming error codes exist in SYS61 and SYS62

3.

At completion of clamp close, observe the pressure reported for first

clamp close segment 2 CPS13 (N43:665). If it is not approximately

equal to the setpoint you entered in CPC13, then check:

- was your valve and solenoid alignment the same for clamp close

profile execution and clamp close action in set-output?

If the observed pressure CPS13 is still not within 20% of CPC13, your

pressure valve is not linear over the desired range. Correct as follows:

If:

And Your Selected

Valve is:

Then change FCC44

(N43:40) as follows:

CPS13 was less than CPC13 Direct Acting

Increase in 5% steps

Reverse Acting

Decrease in 5% steps

CPS13 was more than

CPC13

Direct Acting

Decrease in 5% steps

Reverse Acting

Increase in 5% steps