Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 119

Load Initial Configuration Values

Chapter 7

7-38

Determine Output for Minimum values as follows:

0 (0%) for uni-directional direct acting valves

5000 (50%) for bi-directional valves

9999 (100%) for uni-directional reverse acting valves

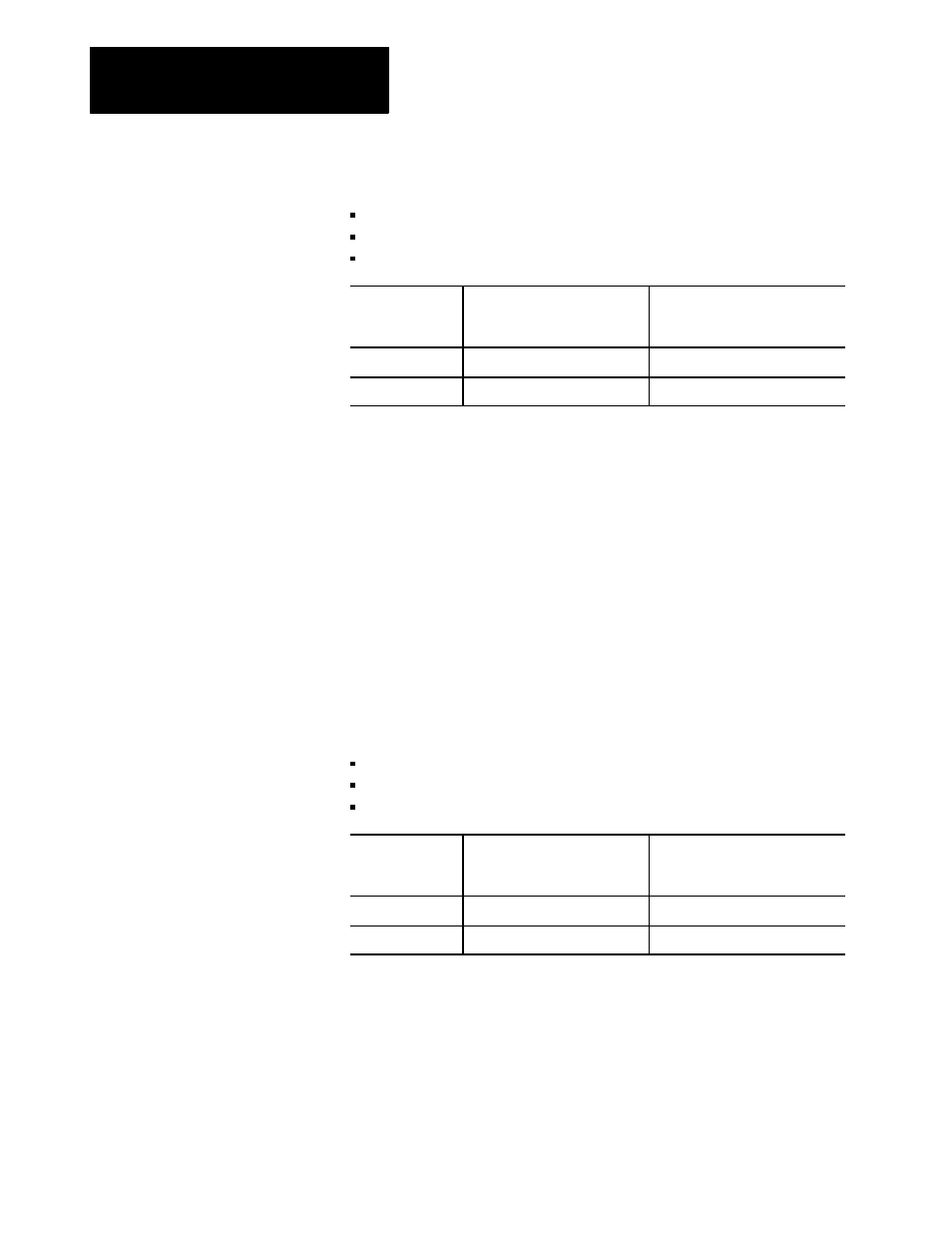

If your selected

velocity valve is:

Then the value in word 47

should be:

And during the profile or stroke,

the QDC module does NOT drive

the valve with a % output:

Direct Acting

less than the value in word 48

less than word 47

Reverse Acting

greater than the value in word 48 greater than word 47

Enter initial Output for Minimum values on corresponding worksheets.

Selected Velocity Valve, Output for Maximum

(FCC48, SCC48, TCC48, INC48, FOC48, SOC48, TOC48, OSC48)

The QDC module uses this word with the Maximum Velocity Control

Limit (word 46) above. Enter the %-signal output that the QDC module

uses to drive the selected velocity valve for maximum profile velocity.

The QDC module expects a velocity equal to word 46 above when setting

the selected velocity valve to this percentage output.

The QDC module uses this setpoint to drive the selected velocity valve

when attempting to attain maximum ram (screw) or clamp velocity. It

should drive the selected velocity valve to a spool position that provides

full hydraulic flow.

Determine Output for Maximum values as follows:

9999 (100%) for uni-directional direct acting valves

0 (0%) or 9999 (100%) for bi-directional valves depending on direction

0 (0%) for uni-directional reverse acting valves

If your selected

velocity valve is:

Then the value in word 48

should be:

And during the profile, the QDC

module does NOT drive the valve

with a % output:

Direct Acting

greater than the value in word 47 greater than word 48

Reverse Acting

less than the value in word 47

less than word 48

Enter initial Output for Maximum values on corresponding worksheets.

Important: The valve spanning procedures in chapter 9 require these

initial velocity control limits. For additional information, refer to section

3 of the Plastic Molding Module Reference Manual (publication

1771-6.5.88).