Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 199

Span Your Valves

Chapter 9

9-42

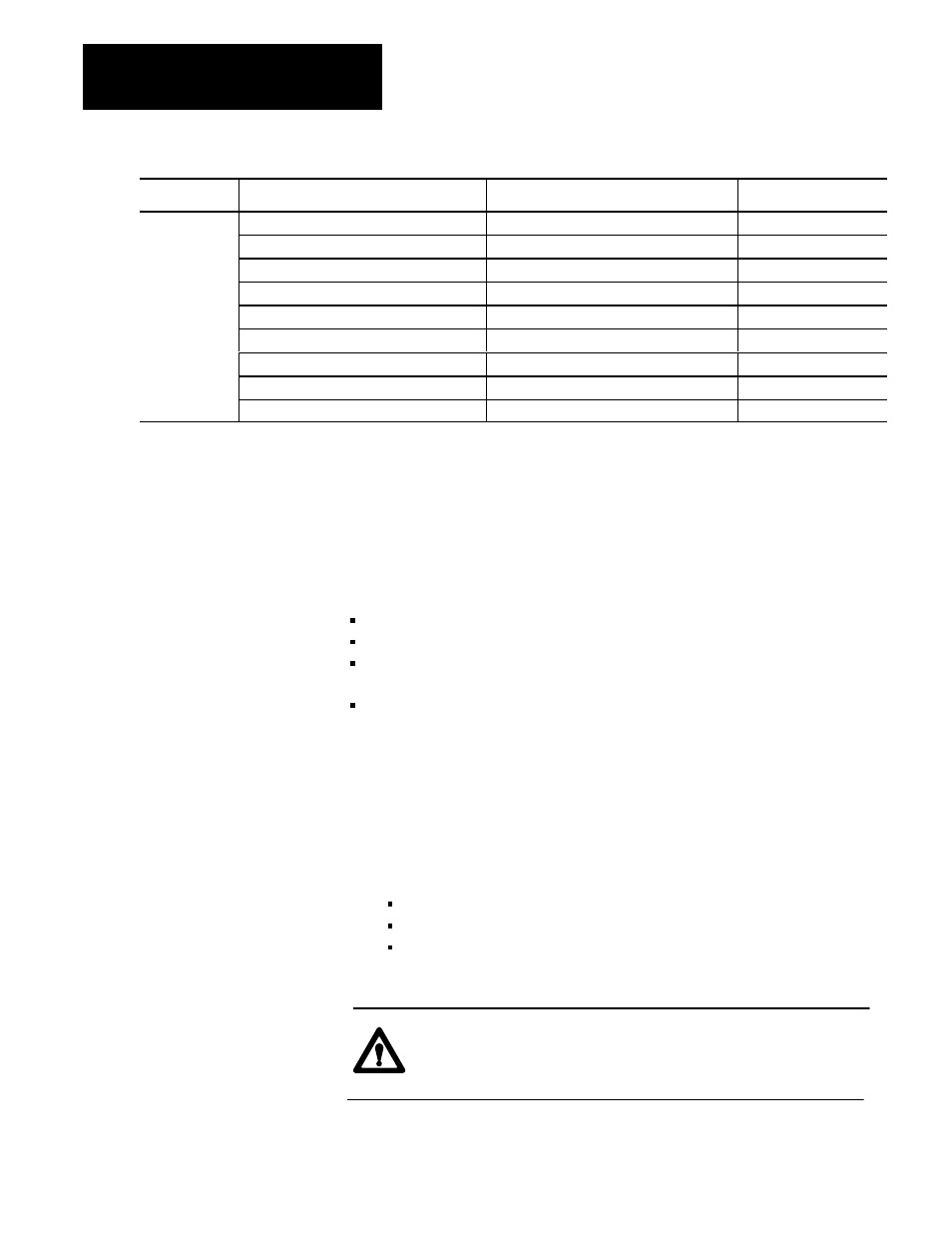

On Worksheet: Confirm Your Configuration:

With These Words or Bits:

ProĆset Addr:

8ĆE

Mold Protection - start open slow on overrun

OPC03ĆB11 = 0

B37/619

Logical bridge - start next profile

OPC03ĆB10 = B09 = B08 = 0

B37/618, 617, 616

Pressure vs. Position control

OPC03ĆB06 = 04 = 02 = 00 = 1

B37/614, 612, 610, 608

Expert Response Compensation (ERC) = Off

OPC04ĆB15 - B08 = 1

B37/639Ć632

OpenĆloop control

OPC04ĆB07 - B00 = 1

B37/631Ć624

FOC segment pressures

OPC10, 13, 16 = your values

N43:546, 549, 552

FOC endĆofĆsegment position setpoints

OPC11, 14, 17 = your values

N43:547, 550, 553

Start OSC position setpoint

OPC61 = your value

N43:597

Mold full open position setpoint

OPC62 = your value

N43:598

If these are not your current values, we suggest that you correct them now

using the download procedure discussed in chapter 4.

Span Your Clamp Open Pressure Valve(s)

Span your clamp pressure valve for smooth operation at highest desired

clamp open pressure. Do this in the following procedure by finding

optimum values for:

Minimum Pressure Control Limit FOC41, SOC41, TOC41, and OSC41

Maximum Pressure Control Limit FOC42, SOC42, TOC42, and OSC42

Selected Pressure Valve, Output For Minimum

FOC43, SOC43, TOC43, and OSC43

Selected Pressure Valve, Output For Maximum

FOC44, SOC44, TOC44, and OSC44

Important: If your machine hydraulics are identical for all clamp open

and open slow profiles, complete the procedure for first clamp open by

finding values for FOC41-44, and copy them into the other clamp open

profile words SOC41-44, TOC41-44, and OSC41-44 when told.

Otherwise, repeat the procedure as needed.

Important: If PanelView is operational for clamp profiles, use it to:

observe actuals

change and download setpoints

run profiles

Important: We suggest that you read this procedure before starting.

ATTENTION: As with any machine start-up, install a test

mold. Programming errors, configuration errors, or hydraulic

problems could lead to machine damage or injury to personnel.