Determine initial sensorćconfiguration values – Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 41

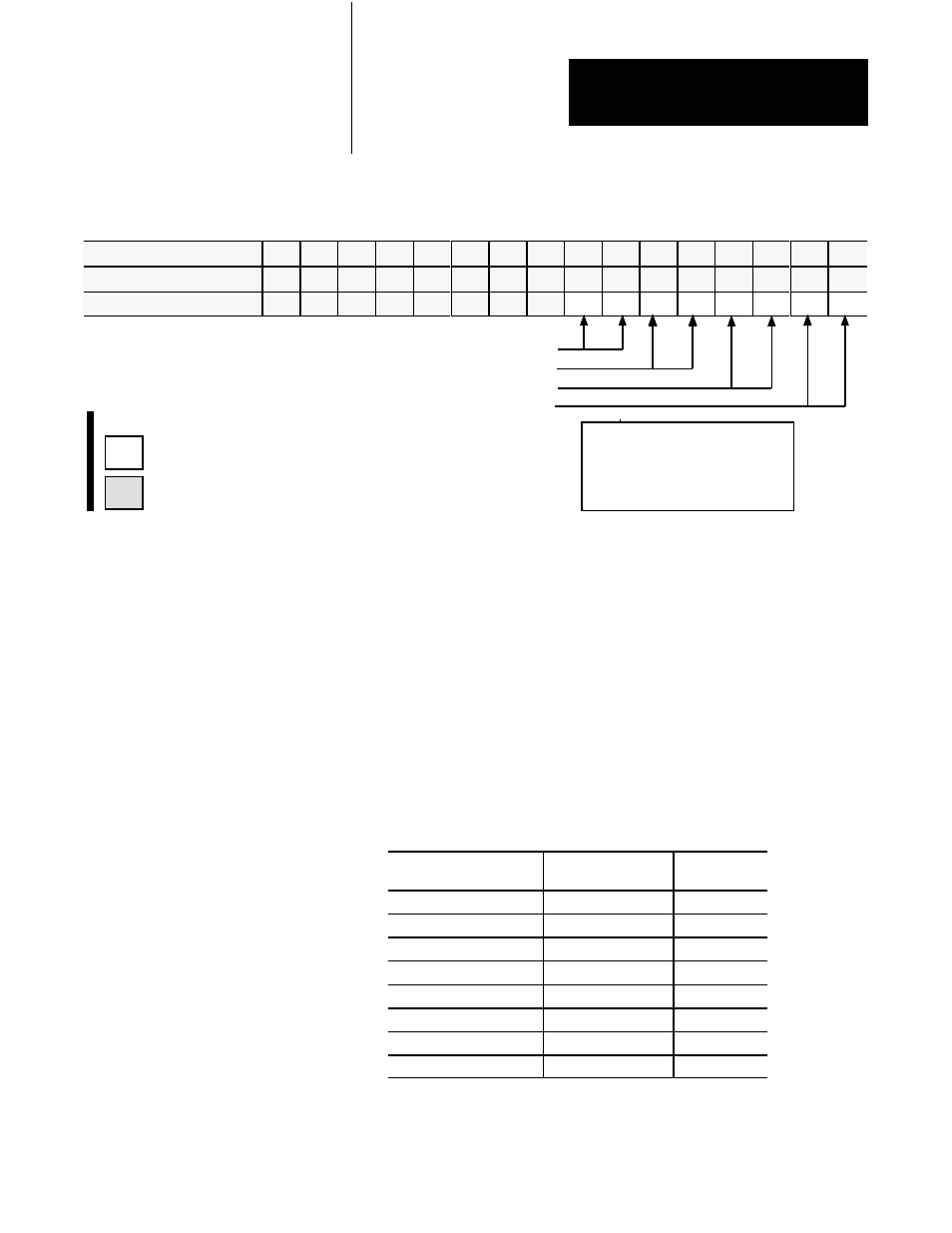

Select Output 1 Range with bits 01, 00

Select Output 2 Range with bits 03, 02

Select Output 3 Range with bits 05, 04

Select Output 4 Range with bits 07, 06

Output Range

-10 to +10V dc 0 0

0 to +10V dc 0 1

4 to 20 mA 1 0

Not connected 1 1

Code:

Your value

Required initial value

loaded by ProĆSet 600

0 or 1

Configure the QDC Module's I/O

Chapter 3

3-3

Worksheet 3ĆC

Select Output Ranges for your Valves

Control Word MCC04ĆBxx

15

14 13 12 11

10

09 08 07 06 05 04 03 02 01 00

ProĆSet 600 Addr. B34/bit

575 574 573 572 571 570 569 568 567 566 565 564 563 562 561 560

Value

1

1

1

1

1

1

1

1

Example: If you select 0-10V dc for all four output ranges:

MCC04 = 11111111 01010101.

Important: Software output selections must match the jumper settings for

each respective output.

To determine initial sensor configuration values, refer to Table 3.A, and

specifications that accompanied your sensors, valves, and cylinders. Write

down applicable values on Worksheet 3-D.

Important: You must enter floating-point numbers and percentages as

integers, so we recommend that you write them in Worksheet 3-D in the

following format: Use an assumed decimal point position that depends on

the range value. For example:

If the Range is:

And You Want to

Enter this Value:

Use this

Format:

0 Ć 099.99%

75%

07500

0 Ć 99.99 inch

7.32 inch

00732

0 Ć 0999.9 mm

432.6 mm

4326

4.00 Ć 020.00 mA

16 mA

01600

0 Ć 010.00V dc

5.6V dc

00560

0 Ć 009.99 sec

0.47 sec

00047

0 Ć 09999 psi

321 psi

00321

0 Ć 0999.9 Bar

222 Bar

2220

Determine Initial

SensorĆconfiguration Values