Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 123

Algorithm

0 = Vel/Pos

1 = Press/Pos

FCC

SCC

TCC

FCC

SCC

TCC

Logical Bridge

0 = Start Next Profile at end

1 = Stop and Set Output at end

Mold Protection

0 = Start LPC on Zone Overrun

1 = Stop and Zero Outputs on Zone Overrun

Velocity Units

0 = Percent Velocity

1 = Inches (mm)/Second

CPC Block Identifier

ERC Enable/Disable Selection

0 = ON

1 = OFF

bit 15 = Press/Pos LPC

bit 13 = Press/Pos TCC

bit 12 = Vel/Pos TCC

bit 11 = Press/Pos SCC

bit 10 = Vel/Pos SCC

Open/ClosedĆLoop Selection

0 = ClosedĆLoop

1 = OpenĆLoop

bit 04 = Vel/Pos TCC

bit 03 = Press/Pos SCC

bit 02 = Vel/Pos SCC

bit 01 = Press/Pos FCC

bit 00 = Vel/Pos FCC

Code:

Your value

Required initial value

loaded by ProĆSet 600

0 or 1

bit 09 = Press/Pos FCC

bit 08 = Vel/Pos FCC

bit 07 = Press/Pos LPC

bit 05 = Press/Pos TCC

Load Initial Profile Values

Chapter 8

8-2

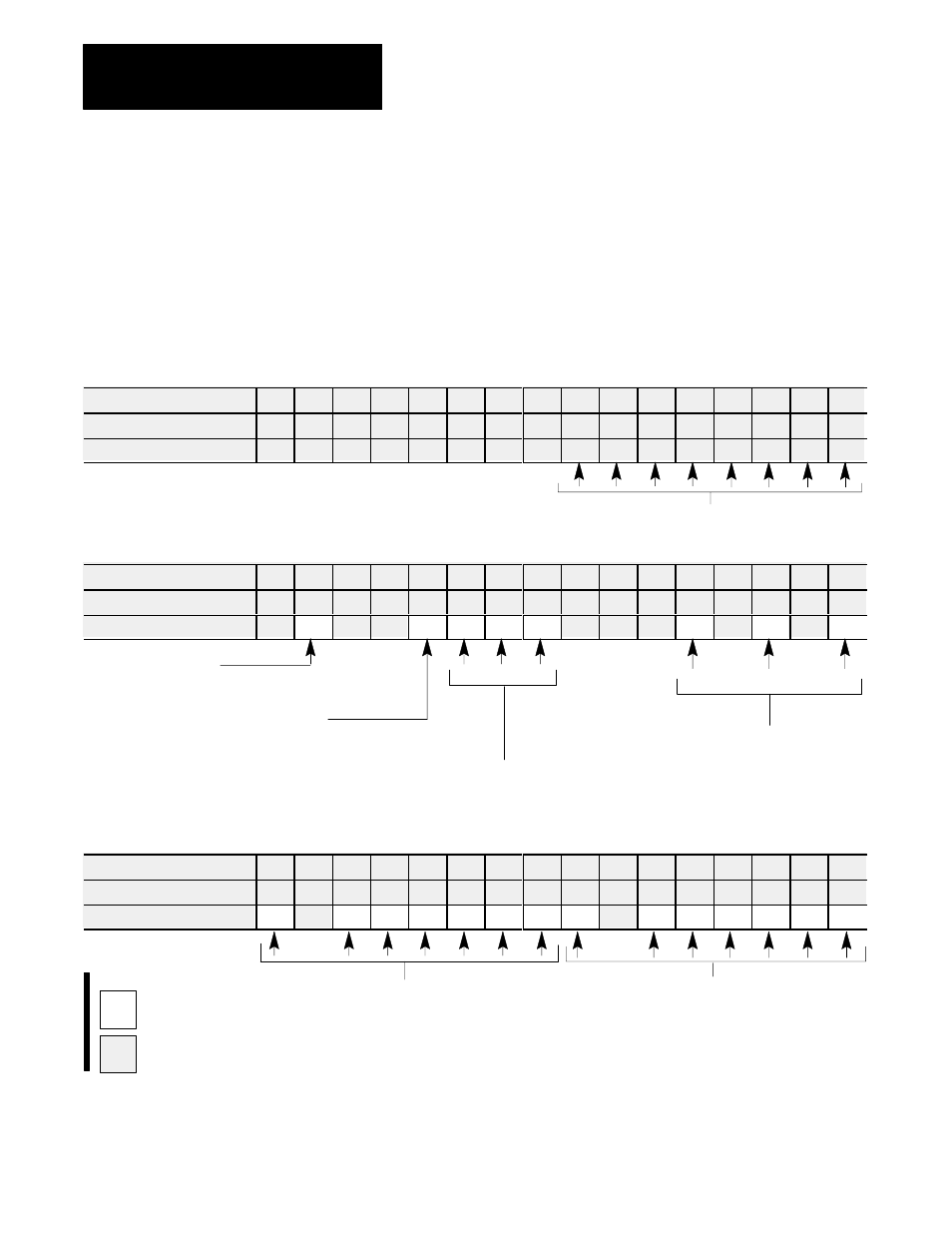

Use Worksheet 8-A to enter setpoints for pressure vs. position and velocity

vs. position clamp close profiles. The valve spanning procedures in chapter

9 require specific values. We have already entered many values for you,

and help you determine other values in the text that follows.

Worksheet 8ĆA

Clamp Close Profile Block (CPC)

Control Word CPC01ĆBxx

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

00

ProĆSet 600 Addr. B37/ bit

271 270 269 268 267 266 265 264 263 262 261 260 259 258 257 256

Value

0

0

0

0

0

0

0

0

0

0

0

0

0

1

1

1

Control Word CPC03ĆBxx

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

00

ProĆSet 600 Addr. B37/bit

303 302 301 300 299 298 297 296 295 294 293 292 291 290 289 288

Value

0

1

0

0

0

0

0

0

0

0

0

1

0

1

0

1

Control Word CPC04ĆBxx

15

14

13

12

11

10

09

08

07

06

05

04

03

02

01

00

ProĆSet 600 Addr. B37/bit

319 318 317 316 315 314 313 312 311 310 309 308 307 306 305 304

Value

1

0

1

1

1

1

1

1

1

0

1

1

1

1

1

1

Determine and Enter

Setpoints for Clamp Close

Profile (CPC)