Span your valves chapter 9 – Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 188

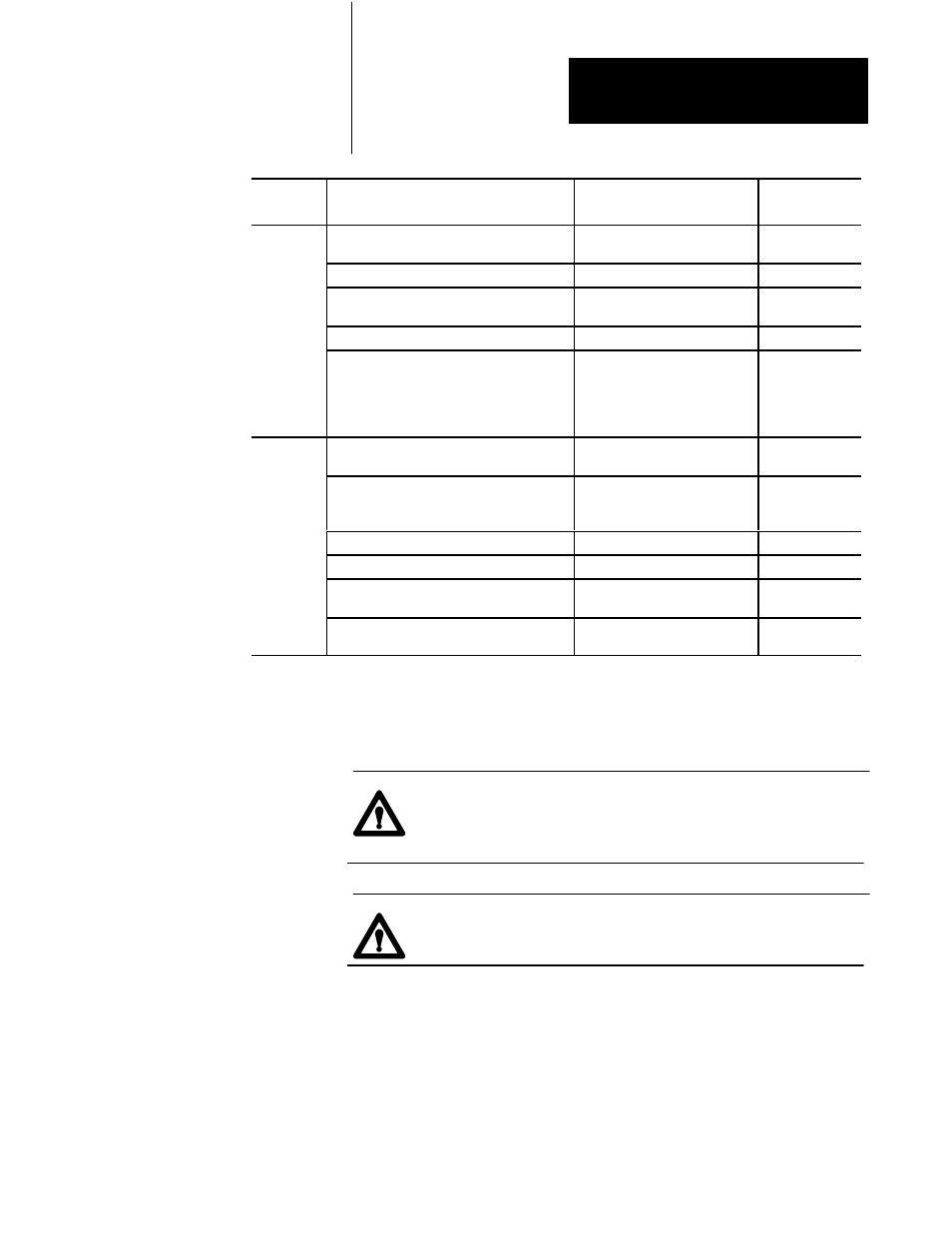

Span Your Valves

Chapter 9

9-31

On

Worksheet

Confirm Your Configuration

With These Words or Bits

for Hold Pressure

ProĆSet Addr

7ĆG

QDC module output to which you connected

your pressure control valve

HDC02ĆB06, B05, B04

B38/212Ć214

SetĆoutput values for unselected valves

HDC09Ć12 = your values

N44:185Ć188

All ramping is disabled with zero ramp rates

HDC17Ć20 = 0

HDC25Ć28 = 0

N44:193Ć196

N44:201Ć204

EndĆofĆprofile setĆoutput values

HDC33Ć36 for zero output

N44:209Ć212

Pressure limits:

Minimum Pressure Control Limit

Maximum Pressure Control Limit

Selected Pressure Valve, Output for Min

Selected Pressure Valve, Output for Max

HDC41 = 0

HDC42 = system pressure

HDC43 = your value

HDC44 = your value

N44:217

N44:218

N44:219

N44:220

8ĆC

Pressure vs Time algorithm

for Pack and Hold

HPC03ĆB02 = B00 = 0

for ram (screw) pressure

B38/288, 290

Logical bridge to stop and set outputs before:

preĆdecompression

plastication

HPC03ĆB08 = 1

HPC03ĆB09 = 1

B38/296

B38/297

OpenĆloop control

HPC04ĆB03, B02, B01, B00 = 1

B38/304Ć307

Expert Response Compensation (ERC) = Off

HPC04ĆB11, B10, B09, B08 = 1

B38/312Ć315

Pressure setpoints

HPC10,13,16,19,22,27,30,33,36,

39 all equal full injection pressure

start @ N44:246

end @ N44:275

Time setpoints

HPC11,14,17,20,23,28,31,34,37

40 all equal to 1 second (100)

start @ N44:247

end @ N44:276

If these are not your current values, we suggest that you correct them now

and download them using the download procedure discussed in chapter 4.

Before proceeding, observe these warnings:

ATTENTION: As with any machine start-up, install a test

mold. Programming errors, configuration errors, or hydraulic

problems could lead to machine damage or injury to personnel.

ATTENTION: Be sure all machine guards and shields are in

place before proceeding.