Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 235

Tune Your Machine

Chapter 10

10-27

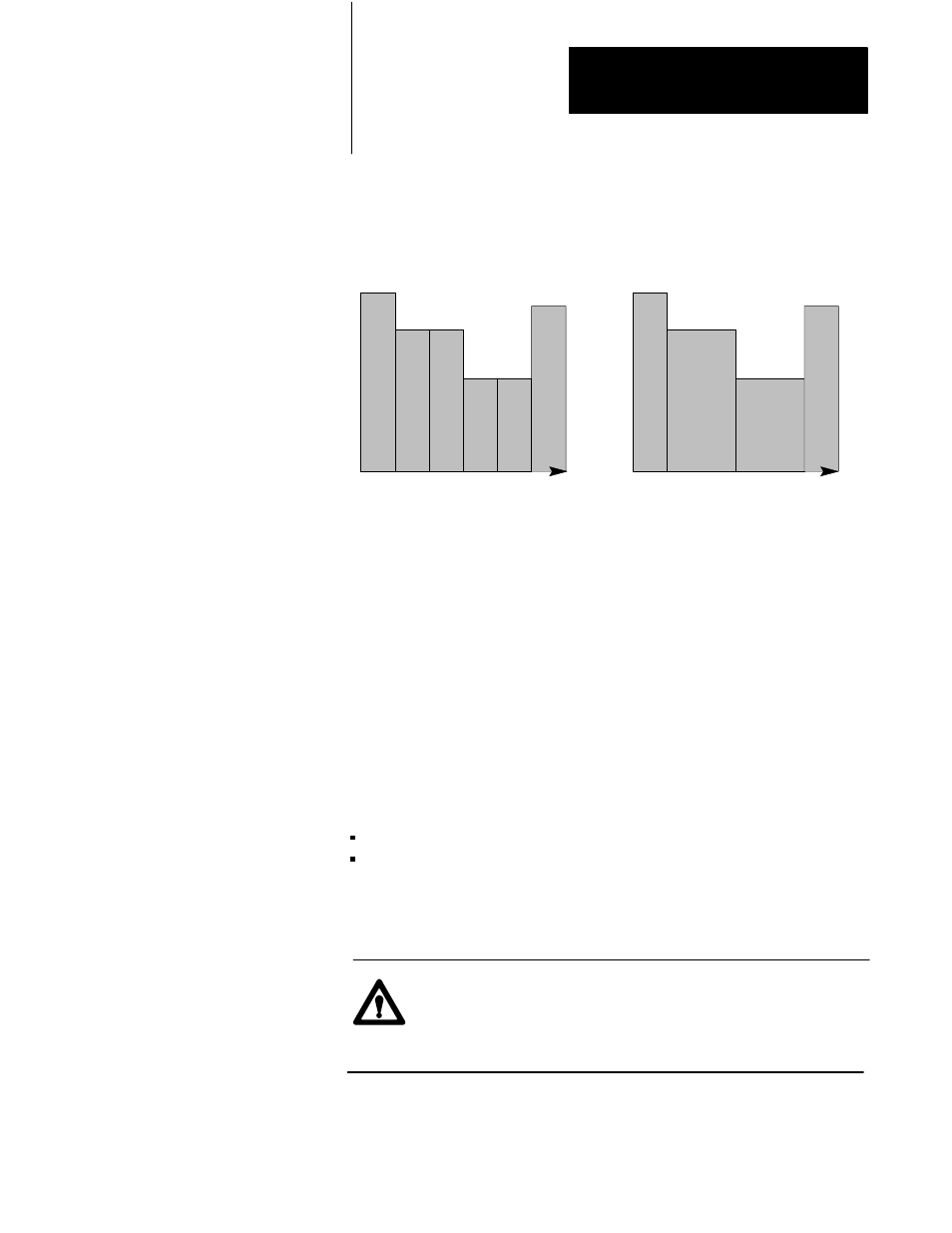

Figure 10.3

Better Control from Fewer and Longer Steps

Clamp Close Profiles

Rather than using a profile with

multiple steps at the same

velocity or pressure...

Use fewer, longer steps

Start Clamp LPC Position Setpoint (CPC61)

The QDC module uses this clamp position as protection against running a

clamp close profile into the mold protection zone. Although you can use it

as an operational setpoint when CPC03-B11 = 0 (see discussion of

End-of-Segment Position Setpoints below), its purpose is to guard against

mold damage resulting from profile entry errors.

Important: This position setpoint should be determined and set only by

qualified personnel, so we do not present it on any Pro-Set 600 screen.

Calculate CPC61 by determining the smallest distance required for the

QDC module to safely assume pressure control:

prior to mating the two mold halves

with the clamp closing at maximum velocity and pressure

By setting this clamp position as stated, you minimize the possibility of

mold damage that could result from changing clamp-close velocity,

pressure, or position setpoints.

ATTENTION: On hydraulic (non-toggle) clamp mechanisms,

re-adjust this parameter to account for mold thickness each time

you install a different mold to guard against damage to the

machine and personal injury.