Overview of remaining configuration procedures – Rockwell Automation 1771-QDC, D17716.5.86(Passport) PLASTIC MOLDING MODULE User Manual

Page 58

Overview of Remaining

Configuration Procedures

Chapter 4

4-3

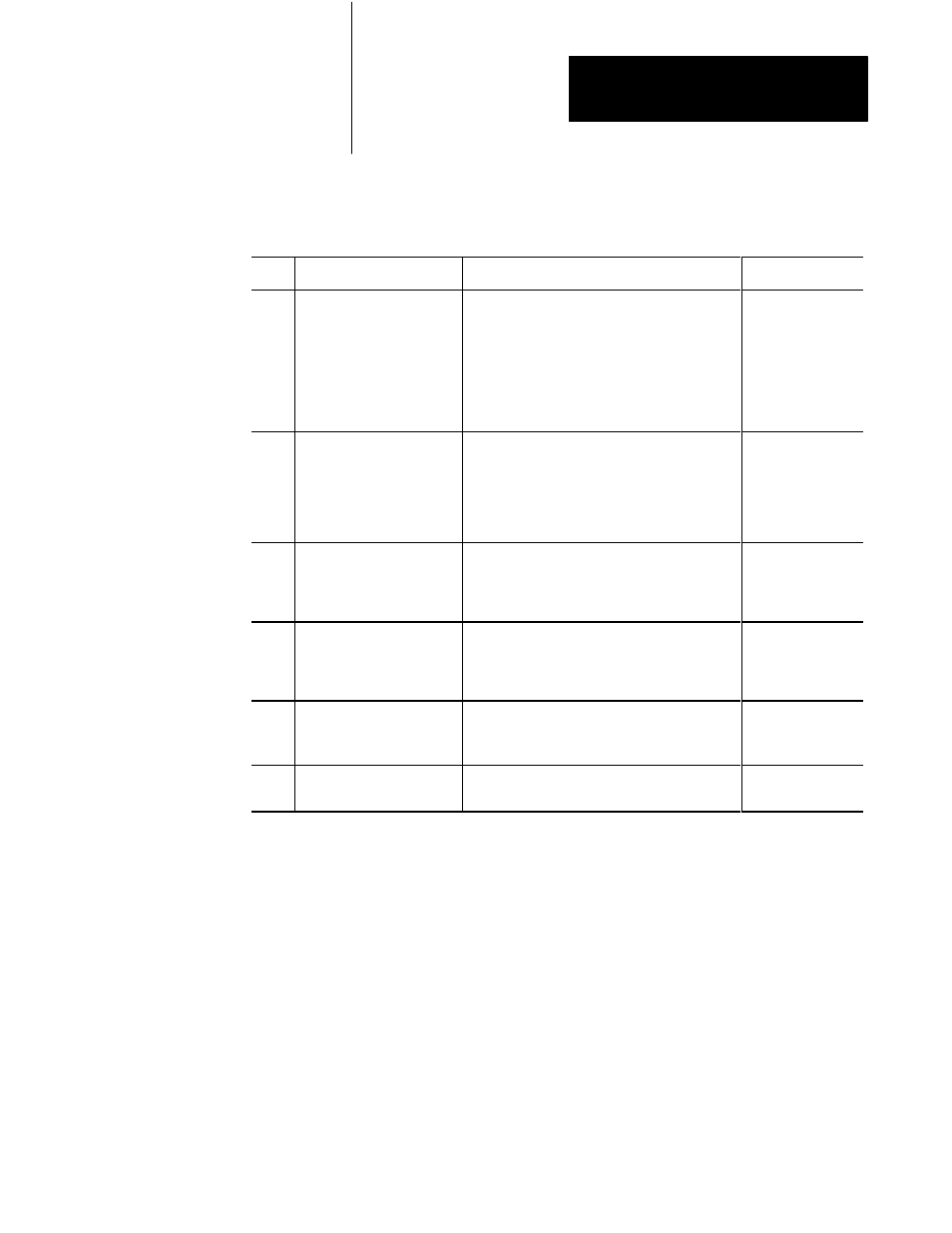

Configuration procedures detailed over the next several chapters are

outlined below. The procedures are sequential in nature: configuration

information determined in initial chapters is needed in later chapters.

Step: Procedure:

Enter this Information:

Refer to:

1

Jog Your Machine

Machine jog pressure and flow setpoints are

entered into the Jog Configuration (JGC) block.

You actually jog your inject and clamp with

commands in the Dynamic Command Block (DYC)

to further refine your jog configuration.

Jog pressure alarm setpoints are configured.

Chapter 5

2

Write a PLCĆ5 Program to

Coordinate Phases

The QDC module offers many machine operation

options to meet nearly any injection molding

machine's requirements.

PLCĆ5 ladder logic is required to cycle the machine

in the desired manner.

Chapter 6

3

Enter Initial

Configuration Values

Valves/Outputs responsible for controlling pressure

or flow, valve spanning values and ramp rates.

Chapter 7

(Used in

Chapters 9 & 10)

4

Enter Initial Profile Values

Initial machine operation setpoints (pressure,

velocity, position, time setpoints, other partĆspecific

information)

Chapter 8

(Used in

Chapters 9 & 10)

5

Span your Valves

Configuration parameters necessary to accurately

span your inject and clamp valves. You also set

profile pressure alarms.

Chapter 9

6

Tune your Machine for

Producing Parts

Topics to consider when machine and part tuning

are discussed.

Chapter 10

Overview of Remaining

Configuration Procedures