MacDon CA25 OM User Manual

Page 69

SECTION 7. OPERATION

169593

67

Revision B

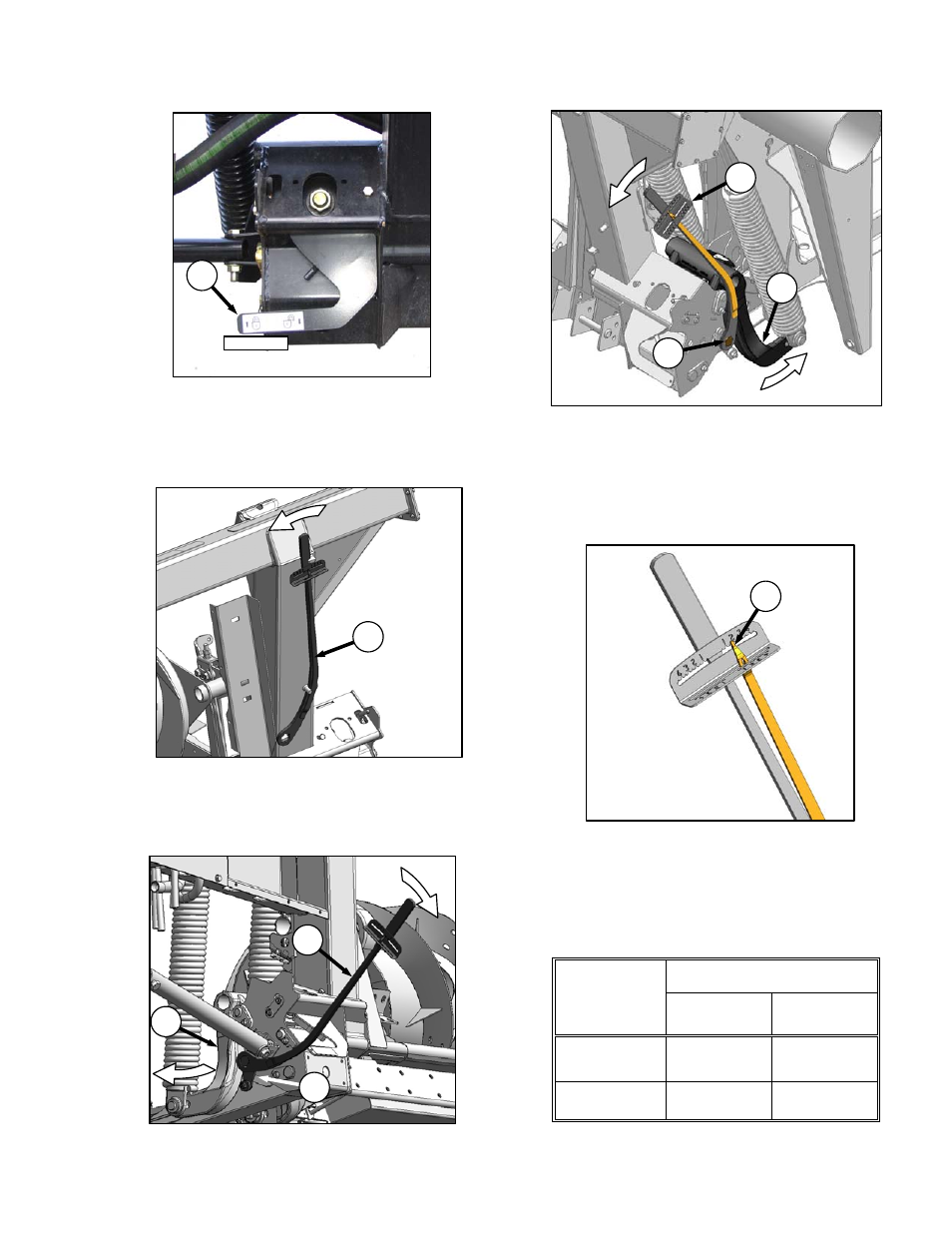

g. Move both header float lock levers (B) down

(UNLOCK).

h. If header is equipped with stabilizer wheels or

slow speed transport wheels, place them in

storage position.

i.

Remove special torque wrench (D) from

storage position at RH side of adapter frame.

Pull slightly in direction shown to disengage

wrench from hook.

j. Place torque wrench (D) onto float lock at (E).

Note position of wrench for checking RH or LH

side.

k. Push down on wrench to rotate bell crank (F)

forward.

l. Continue pushing down on the wrench until

indicator (G) reaches a maximum reading and

begins to decrease. Note the maximum

reading. Repeat for opposite side.

Use the table below as a guide for float

settings.

HEADER SIZE

(FT)

TORQUE SETTINGS

CUTTING ON

THE GROUND

CUTTING OFF

THE GROUND

20, 25, 30

and 35 FT

1-1/2 to 2

2 to 2-1/2

40 and 45 FT

2 to 2-1/2

2-1/2 to 3

(continued next page)

D

LEFT SIDE

F

E

D

G

RIGHT SIDE

E

D

F

UNLOCK

B