Warning – MacDon CA25 OM User Manual

Page 133

SECTION 8. MAINTENANCE AND SERVICING

169593

131

Revision B

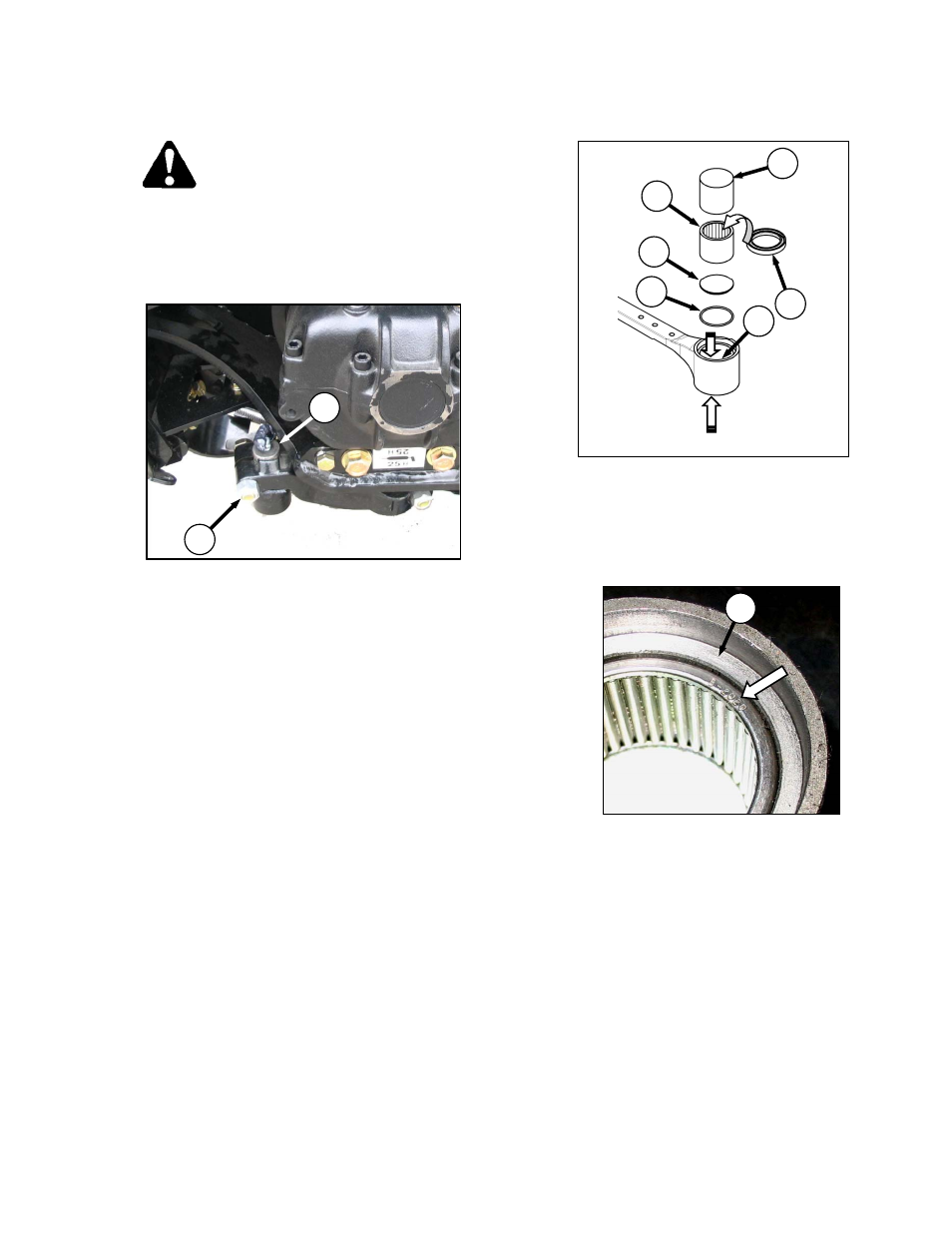

8.9.2 Sickle Removal

WARNING

Stand to rear of sickle during removal to

reduce risk of injury from cutting edges.

Wear heavy gloves when handling sickle.

a. Stroke sickle to its outer limit, and clean area

around sickle head.

b. Remove zerk from pin (A).

c. Remove nut and bolt (B).

d. Insert screwdriver in groove of pin (A), and pry

up on sickle head pin to free sickle. Pin does

not have to be removed from arm.

e. Seal bearing in sickle head with plastic or tape.

f. Wrap a chain around sickle head, and pull

sickle out.

NOTE

For single drive sickles with splice

plate, remove bolts from splice plate,

and pull sickle out from both ends.

8.9.3 Sickle Head Bearing Replacement

8.9.3.1 Bearing

Removal

a. Remove sickle. Refer to previous section.

b. Using a flat-ended tool (D) with approximately

the same diameter as the plug (E), tap out the

seal (F), bearing (G), and plug from the

underside of the head.

NOTE

The seal can be replaced without

removing the bearing. When

changing seal, check pin and needle

bearing for wear. Replace if

necessary.

8.9.3.2 Bearing

Installation

a. Place O-ring (C) and plug (E) in sickle head.

IMPORTANT

Install the bearing with the stamped

end (the end with identification

markings) against the tool.

b. Using a flat-ended tool (D) with approximately

the same diameter as the bearing (G), push the

bearing into the sickle head until the top of the

bearing is flush with the step (H) in sickle head.

c. Install seal (F) in top of sickle head with lip

facing outwards.

IMPORTANT

To avoid premature sickle head or

sickle drive box failure, be sure

there is no looseness in:

fit of sickle head pin and needle

bearing, and

fit of sickle head pin and pitman arm.

REMOVAL

C

D

H

G

F

E

H

B

A