Danger – MacDon CA25 OM User Manual

Page 154

SECTION 8. MAINTENANCE AND SERVICING

169593

152

Revision B

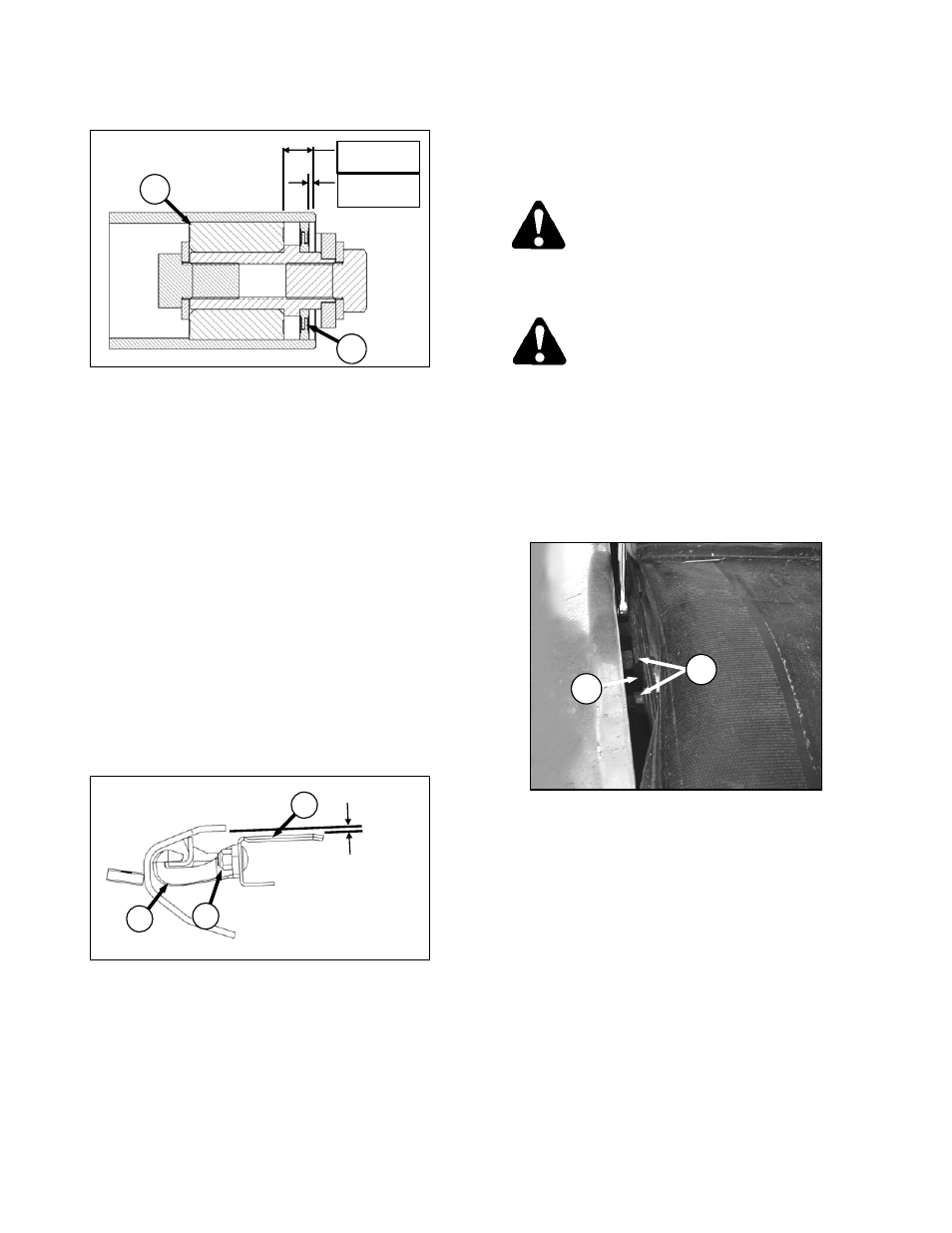

d. Install bearing and seal as follows:

1. Install bearing assembly (E) into roller by

pushing on outer race of bearing. The

bearing is fully positioned when the

9/16 inch (14 mm) dimension is achieved.

2. Apply grease in front of bearing. Refer to

Section 8.3.4 Recommended Fluids and

Lubricants.

e. Install seal (D) as follows:

1. Locate seal at roller opening, and position a

flat washer (1 in. I.D. X 2 in. O.D.) on seal.

2. Using a suitable socket to locate on the

washer, tap seal into roller opening until it

seats on the bearing assembly. The seal is

fully positioned when the 1/8 in. (3 mm)

dimension is achieved. See illustration

above.

f. Re-install roller assembly. Refer to Section

8.11.4 Draper Roller Maintenance.

8.11.5 Deck Height

To prevent material from entering drapers and

cutterbar, maintain deck height so that draper

runs just below cutterbar with maximum 1/32 in.

(1 mm) gap, or with draper deflected down

slightly (up to 1/16 in. [1.5 mm] to create a seal.

The illustration shows the adjustment without

the draper.

NOTE

Measurement is at supports with

header in working position, and decks

slid fully ahead.

Adjust as follows:

DANGER

Engage header lift cylinder stops and reel

props before working under header or

reel.

DANGER

To avoid bodily injury or death from

unexpected start-up or fall of raised

machine, stop engine, remove key, and

engage lift cylinder locks before going

under machine for any reason.

a. Loosen tension on draper. Refer to Section

8.11.1 Header Draper Tension Adjustment.

b. Lift draper up at front edge past cutterbar.

c. Loosen two lock-nuts (A) (four if it is an endless

draper) one-half turn only on deck support (B).

There are two to four supports per deck,

depending on header size.

d. Tap deck (C) to lower deck relative to supports

to achieve setting recommended above. Tap

support (B) using a punch to raise deck relative

to support.

e. Tighten deck support hardware (A).

f. Tension draper. Refer to Section 8.11.1

Header Draper Tension Adjustment.

B

A

B

A

1/4

–

5/16 in.

(7

–

8 mm)

C

9/16 in.

(14 mm)

1/8 in.

(3 mm)

D

E