Danger – MacDon CA25 OM User Manual

Page 67

SECTION 7. OPERATION

169593

65

Revision B

7.9.1.2

Cutting On The Ground

Cutting on the ground is controlled with a

combination of skid shoes, header angle, and

float adjustment, and not with the header lift

cylinders.

NOTE

Skid shoes are standard equipment

on the D65 header.

Having the header ride on the skid shoes allows

the float linkage to float the header over

obstacles and follow ground contours, rather

than supporting the header with the cylinders.

Lowering the skid shoes or decreasing the

header angle increases the cutting height. This

may be desirable in stony conditions, to reduce

damage to cutting components. Also, a longer

stubble length helps material dry faster.

Raising the skid shoes and increasing the

header angle allows the crop to be shaved.

Refer to Section 7.8.1 Header Settings for

recommended skid shoe positions in specific

crops and crop conditions.

Set up the header as follows:

a. Fully raise the stabilizer wheels, or slow speed

transport wheels if installed. Refer to previous

section.

DANGER

To avoid bodily injury or death from

unexpected start-up or fall of raised

machine, stop engine, remove key, and

engage lift cylinder stops before going

under machine to adjust skid shoes or for

any reason.

b. Fully raise header, engage lift cylinder stops,

shut off engine and remove key.

c. Adjust skid shoes to achieve desired cutting

height as follows:

Outer Skid Shoes

1. Remove lynch pin (A) at each skid shoe

(B).

2. Hold shoe, and remove pin (C) by

disengaging frame, and then pulling away

from shoe.

3. Raise or lower skid shoe to desired position

using holes in support as a guide.

4. Re-install pin (C), engage in frame, and

secure with lynch pin (A).

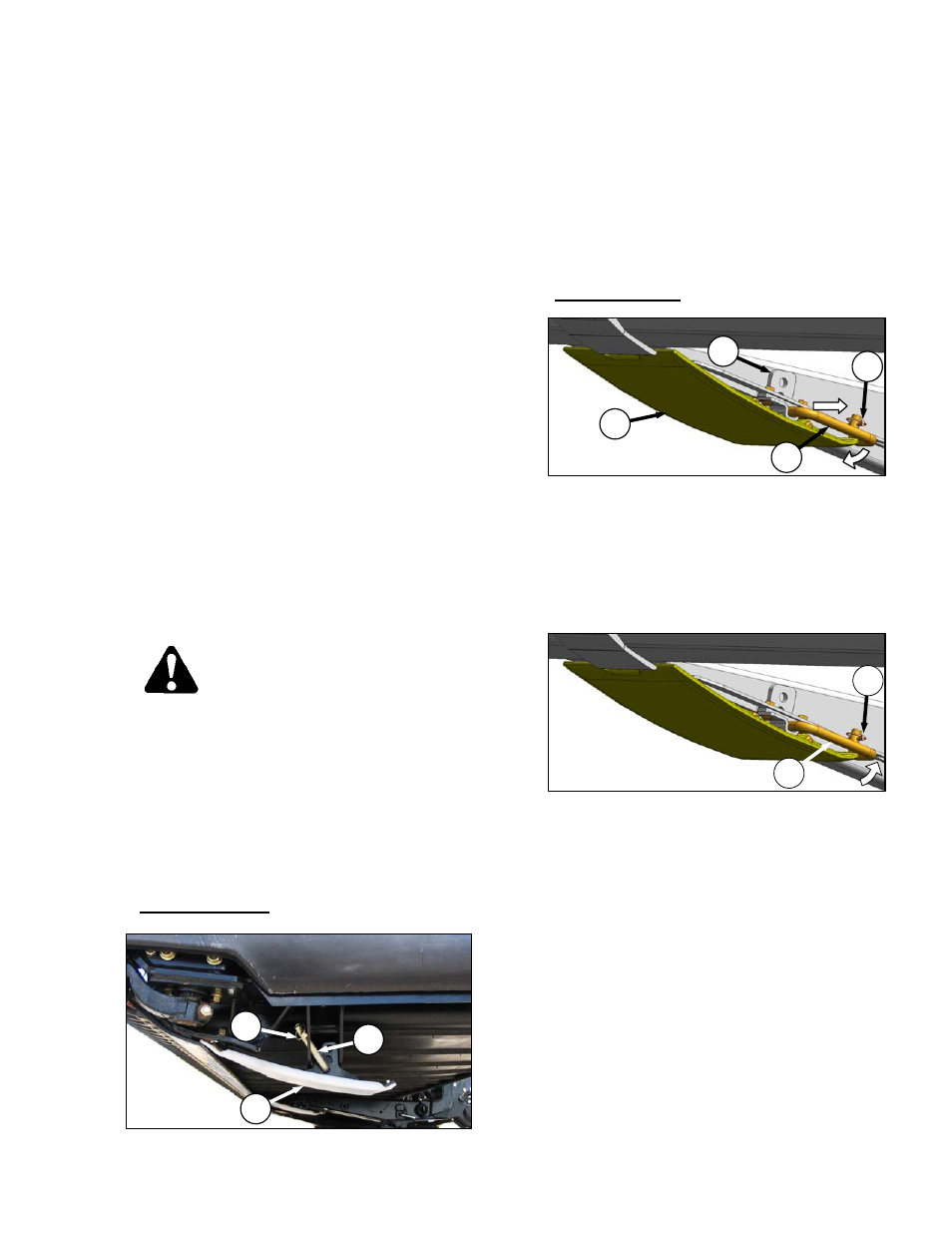

Inner Skid Shoes

1. Remove lynch pin (D).

2. Hold shoe (E), and remove pin (F) by

pulling down to disengage frame, and then

pulling away from shoe.

3. Raise or lower skid shoe (E) to desired

position using holes in support (G) as a

guide.

4. Re-insert pin (F), engage in frame, and

secure with lynch pin (D).

d. Check that skid shoes are adjusted to the same

position.

e. Adjust header angle to desired working position

using the machine’s header angle controls. If

angle is not critical, set it to mid-position.

f.

Check header float as described in the following

Section 7.9.2 Header Float.

E

D

F

G

D

F

B

C

A