Caution – MacDon CA25 OM User Manual

Page 142

SECTION 8. MAINTENANCE AND SERVICING

169593

140

Revision B

C

8.9.9.2 Right End Drive

CAUTION

To avoid person

al

injury, before servicing

machine or opening drive covers, follow

procedures in Section 8.1 PREPARATION

FOR SERVICING.

Tension Adjustment: Timing Belt

IMPORTANT

To prolong belt and drive life, do

NOT over-tighten belt.

Refer to 8.9.9.1. Left End Drive: Tension

Adjustment: Timing Belt.

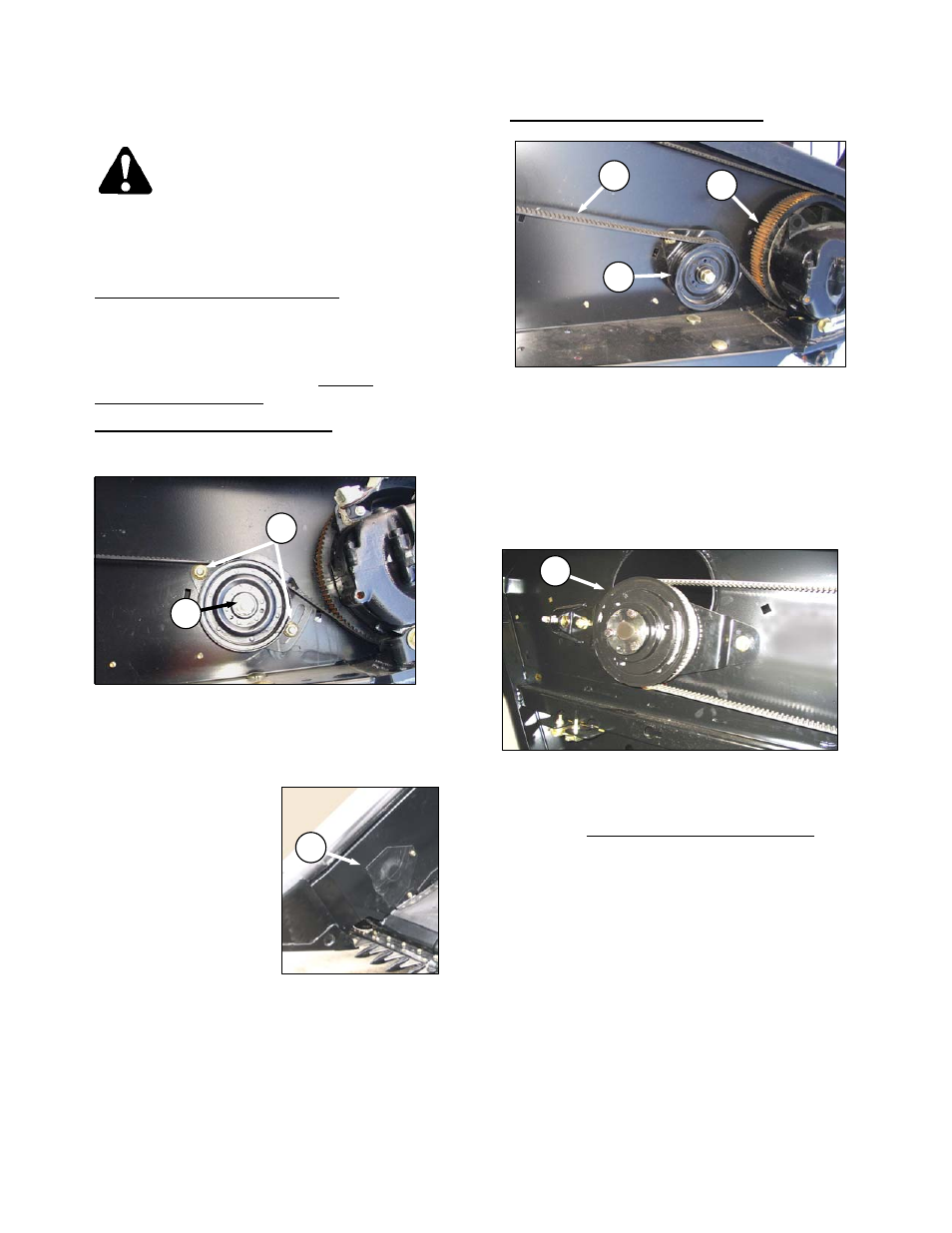

Removal: Right End Timing Belt

a. Open right endshield.

b. Loosen two nuts (A) on belt idler bracket to

relieve tension on belt.

c. Loosen nut (B) on idler pulley, and slide idler

down to loosen belt.

d. Remove bolt in plate (C)

in right endsheet at sickle

drive box, and remove

plate. This provides

clearance between pulley

and endsheet for belt

when it is removed.

e. Slip timing belt off sickle

drive box pulley, and

route belt between sickle

drive box pulley and

endsheet.

f.

Remove belt from drive pulley.

Installation: Right End Timing Belt

a. Route timing belt (D) between sickle drive box

pulley (E) and endsheet, and locate on sickle

drive box pulley, and over idler (F).

NOTE

When installing new belt, never pry

belt over pulley. Be sure adjusting

device is fully loosened, then tension

belt.

b. Position timing belt on drive pulley (G).

c. Adjust timing belt tension, and check belt

clearance to belt guide. Refer to 8.9.9.1. Left

End Drive, Tension Adjustment: Timing Belt.

d. Re-install plate (C) in endsheet.

e. Close left endshield.

f. Re-adjust tension of a new belt after a short

run-in period (about 5 hours).

G

A

B

D

E

F