Caution, Danger – MacDon CA25 OM User Manual

Page 149

SECTION 8. MAINTENANCE AND SERVICING

169593

147

Revision B

8.11 HEADER

DRAPERS

CAUTION

To avoid personal injury, before servicing

machine or opening drive covers, follow

procedures in Section 8.1 PREPARATION

FOR SERVICING.

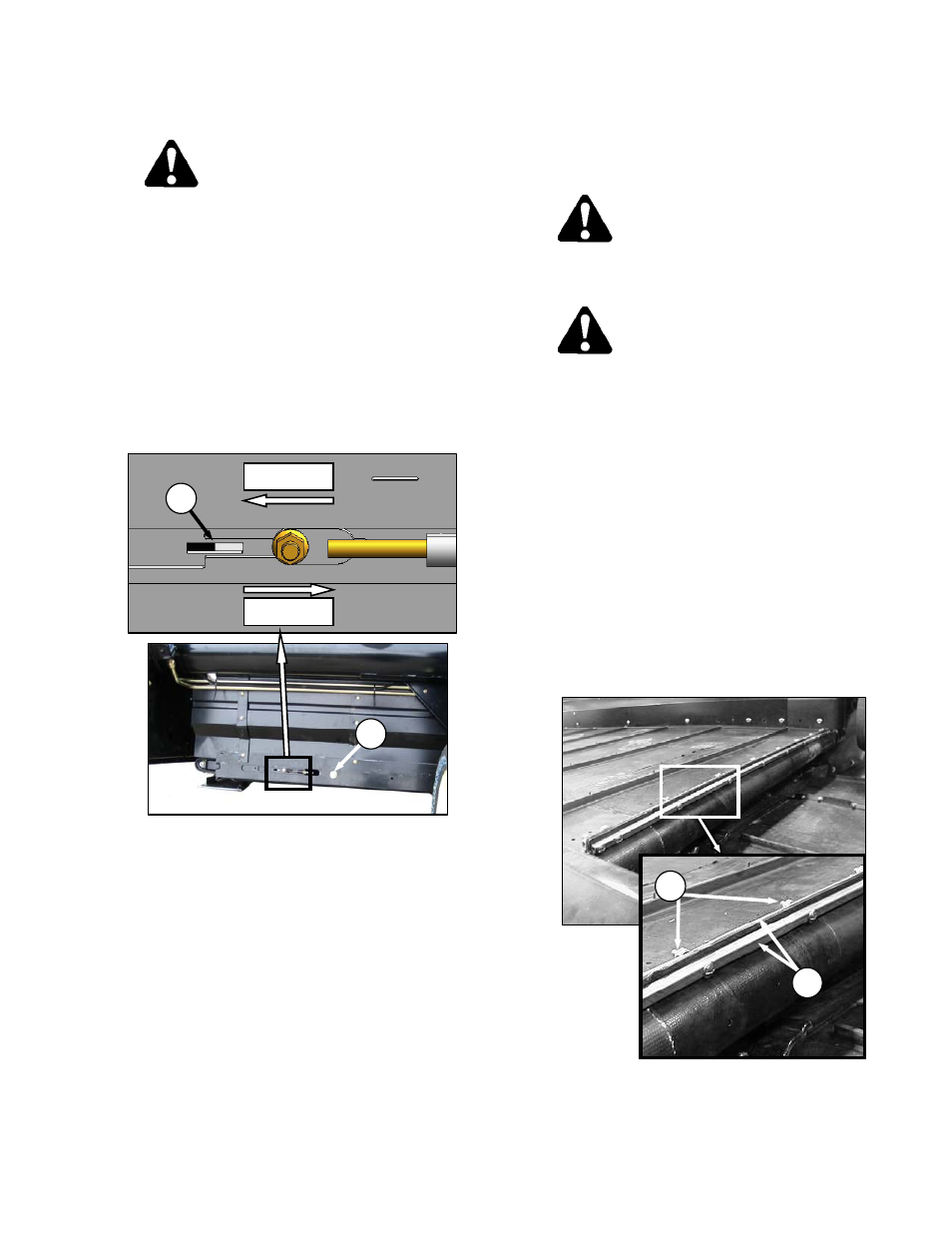

8.11.1 Header Draper Tension Adjustment

Draper tension should be just enough to

prevent slipping, and keep draper from sagging

below cutterbar. Set draper tension as follows:

a. Check that draper guide (rubber track on under-

side of draper) is properly engaged in groove of

drive roller, and that idler roller is between the

guides.

b. Turn bolt (A) clockwise (tighten), and the white

indicator bar (B) will move inboard in direction

of arrow (indicating that draper is tightening).

Tighten until bar is about halfway in window.

IMPORTANT

To avoid premature failure of

draper, draper rollers and/or

tightener components, do NOT

operate with tension set so that

white bar is not visible.

Also to prevent draper from

scooping dirt, ensure draper is tight

enough that it does not sag below

point where cutterbar contacts the

ground.

8.11.2 Replacing Split Draper

The draper should be replaced or repaired if it

is torn, missing slats, or cracked.

CAUTION

To avoid bodily injury from fall of raised

reel, always engage reel props before

going under raised reel for any reason.

DANGER

To avoid bodily injury or death from

unexpected start-up or fall of raised

machine, stop engine, remove key, and

engage lift cylinder locks before going

under machine for any reason.

8.11.2.1 Draper

Removal

a. Raise reel, and engage reel props.

b. Raise header, and install lift cylinder locks.

c. Stand in draper opening or on combine feed

draper, and move draper until draper joint is in

work area.

NOTE

Deck can also be shifted towards

center to provide opening at endsheet.

d. Release tension on the draper. Refer to

previous section.

e. Remove nuts (C) and tube connectors (D) at

draper joint.

f.

Pull draper from deck.

C

D

LH IDLER ROLLER ADJUST - RH OPPOSITE

B

A

TIGHTEN

LOOSEN