Danger – MacDon CA25 OM User Manual

Page 152

SECTION 8. MAINTENANCE AND SERVICING

169593

150

Revision B

8.11.4 Draper Roller Maintenance

The draper rollers have non-greaseable

bearings.

The external seal should be checked every

200 hours (and more frequently in sandy

conditions) to obtain the maximum bearing life.

DANGER

Engage header lift cylinder stops and reel

props before working under header or

reel.

8.11.4.1 Drive

Roller

Removal

a. Raise header and reel and engage cylinder and

reel stops.

b. On deck shift headers, position deck so drive

roller is easily accessible.

c. Loosen and uncouple draper. Refer to Section

8.11.2 Replacing Split Draper.

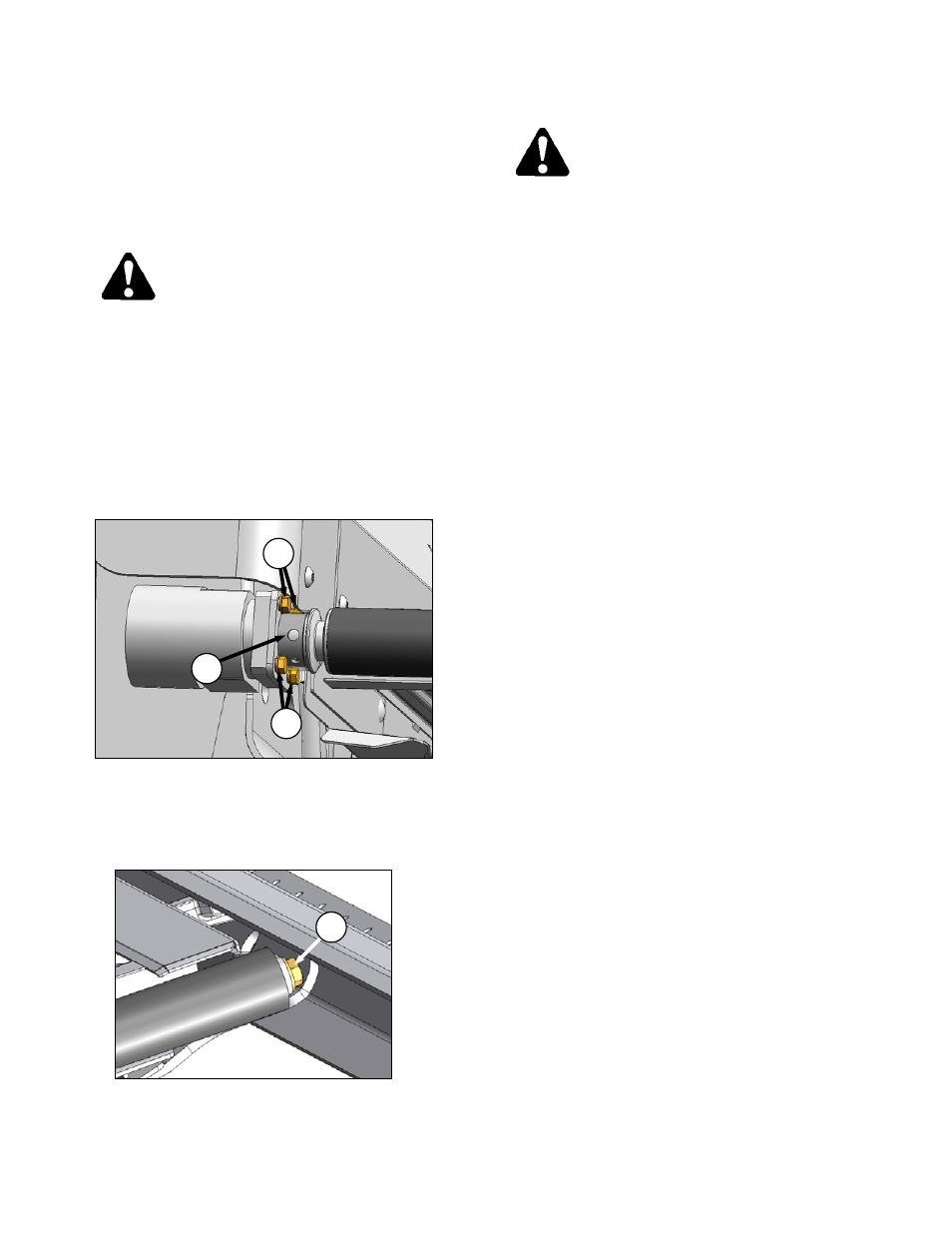

d. Loosen the two set screws in access hole (A) in

the drive roller hub at motor end.

e. Remove the four bolts (B) that hold hydraulic

motor to arm, and pull motor off roller.

f. Remove bolt (C) at forward end of roller, and

remove roller from deck.

8.11.4.2 Drive

Roller

Installation

DANGER

Engage header lift cylinder stops and reel

props before working under header or

reel.

Refer to illustrations opposite.

a. Position roller in deck arms, and secure forward

end with bolt (C) and washer. Do not tighten at

this time.

b. Apply SAE Multi-Purpose grease to motor shaft,

locate motor on roller arm, and engage motor

shaft into roller.

c. Secure motor with shoulder bolts (B), and

tighten. The shoulder bolts allow clearance

between the motor and arm. The motor is NOT

secured tightly to arm.

d. Push roller against shoulder on motor shaft,

and hand-tighten the two set screws (A).

Torque set screws to 20 ft·lbf (27 N·m).

e. Torque bolt (C) to 70 ft·lbf (95 N·m).

f. Re-attach draper. Refer to Section 8.11.2

Replacing Split Draper.

g. Adjust draper tension. Refer to Section 8.11.1

Header Draper Tension Adjustment.

h. Re-adjust hydraulic motor hoses (if required),

and tighten hose clamps.

i. Run machine, and adjust tracking if required.

Section 8.11.3 Header Draper Alignment.

C

A

B

B