Caution – MacDon CA25 OM User Manual

Page 65

SECTION 7. OPERATION

169593

63

Revision B

7.9 HEADER OPERATING VARIABLES

Satisfactory function of the header in all

situations requires making proper adjustments

to suit various crops and conditions.

Correct operation reduces crop loss and allows

cutting of more acres. As well, proper

adjustments and timely maintenance will

increase the length of service you receive from

the machine.

The variables listed below and detailed on the

following pages will affect the performance of

the machine. You will quickly become adept at

adjusting the machine to give you the desired

results.

VARIABLE

SECTION

Cutting Height

7.9.1

Header Float

7.9.2

Header Angle

7.9.3

Reel Speed

7.9.4

Ground Speed

7.9.5

Draper Speed

7.9.6

Knife Speed

7.9.7

Reel Height

7.9.8

Reel Fore-Aft Position

7.9.9

Reel Tine Pitch

7.9.10

Crop Divider Rods

7.9.11

7.9.1 Cutting

Height

Harvest Headers are designed to allow an

Operator to cut the crop above the ground for a

desired stubble height, or to cut the crop at

ground level with the header on the ground.

Cutting height will vary, depending on factors

including whether windrowing or straight-

cutting, type of crop, etc.

7.9.1.1

Cutting Off The Ground

Cutting height is controlled with a combination

of header lift cylinder adjustment and a

stabilizer wheel system, or a stabilizer/slow

speed transport wheel system.

The stabilizing wheel system in both options is

designed to minimize bouncing at the header

ends, and may be used to float the headers to

achieve an even cutting height when cutting

above ground level in cereal grains.

The system can provide very even stubble

height and greatly reduced operator fatigue.

The proper setting requires ‘balancing’ the

amount of header weight carried by the float

and the stabilizer wheels.

Refer to Section 7.8.1 Header Settings for

recommended use in specific crops and crop

conditions.

CAUTION

Stop engine, and remove key from ignition

before leaving Operator's seat for any

reason. A child or even a pet could engage

an idling machine.

a. Raise the header so that the stabilizer wheels

are off the ground. Shut down engine, and

remove the key.

b. Check that the float is working properly. See

Section 7.9.2 Header Float.

c. Set up the stabilizer wheels, if installed, as

follows: Otherwise, proceed to step d. on next

page.

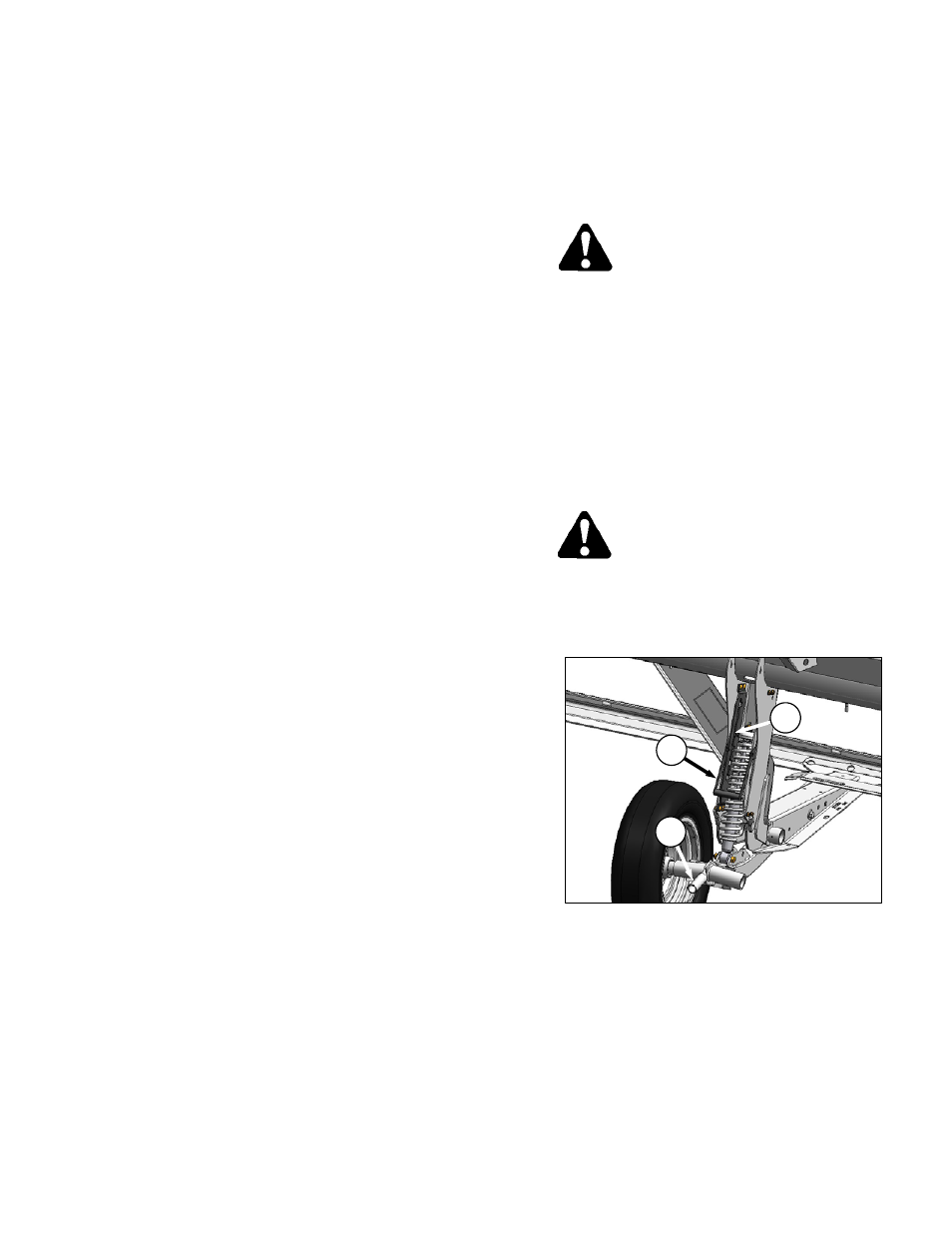

CAUTION

Handle may be under tension, especially

when the wheels are on the ground. Raise

header so that wheels are off the ground

before making adjustments.

1. Support wheel weight by lifting slightly with

one hand on handle B. Pull up on handle

(A) to release lock.

2. Lift wheel with handle (B) and engage

support channel into center slot (C) in

upper support.

3. Push down on handle (A) to lock.

(continued next page)

LH SHOWN - RH OPPOSITE

A

C

B