Caution – MacDon CA25 OM User Manual

Page 68

SECTION 7. OPERATION

169593

66

Revision B

7.9.2 Header

Float

D65 combine headers perform best with

minimum extra weight on the header, under

normal conditions.

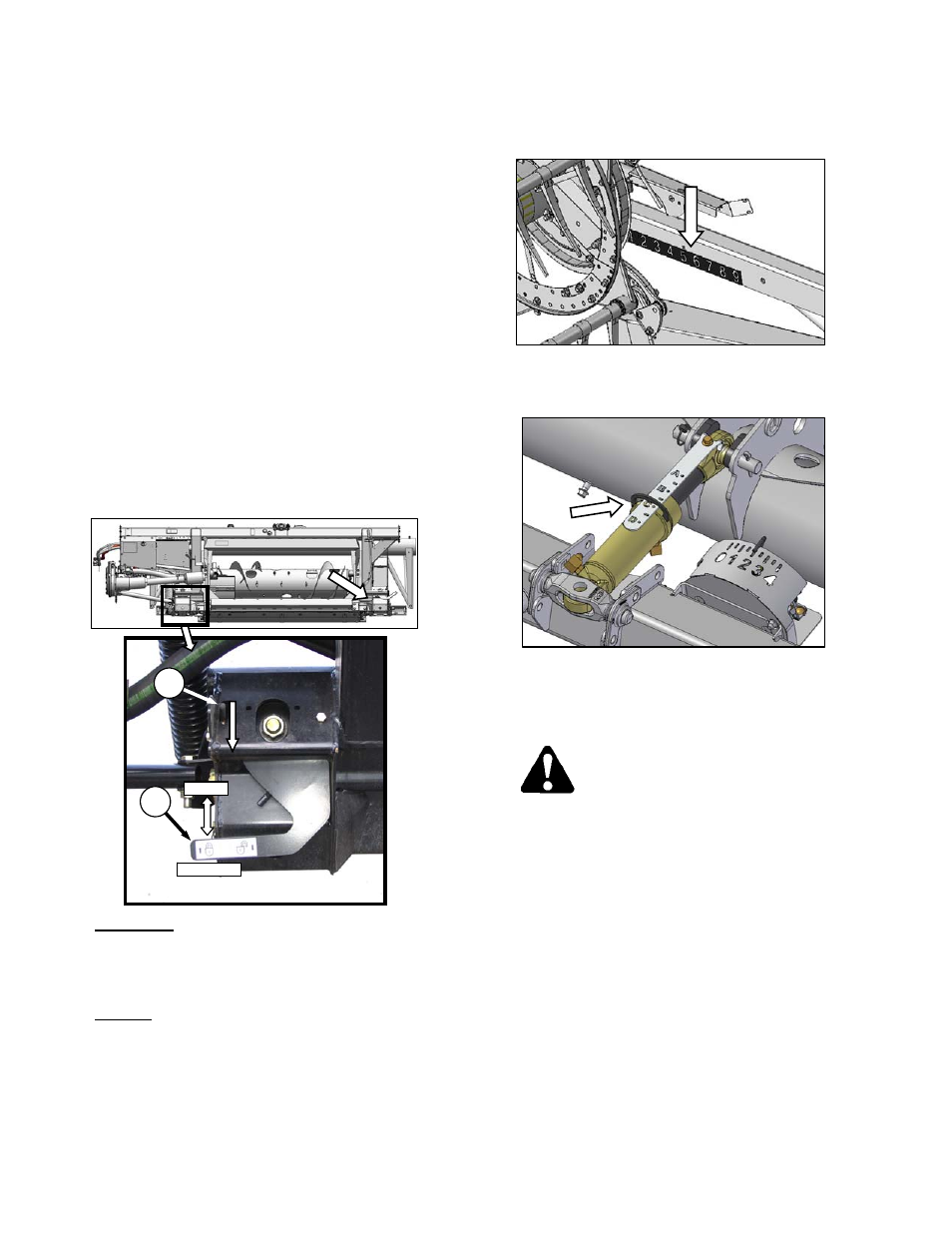

7.9.2.1

Header Float Locks

The function of the header float locks is to lock

and unlock the header float system. There are

two locks - one on each side of the adapter.

IMPORTANT

The float locks must be engaged

when the header is being

transported with the adapter

attached so there is no relative

movement between the adapter and

header during transport.

The float locks must also be locked

during detachment from the

combine to allow the feeder house

to release the adapter.

a. Disengage float locks by moving latch (A)

downward, and moving lever (B) at each lock to

lowest position. In this position, the header is

unlocked, and can float with respect to the

adapter.

b. Engage the float locks by moving lever (B) up

to its highest position. In this position, the

header cannot move with respect to the

adapter.

7.9.2.2

Checking and Adjusting Float

a. Park combine on level surface.

b. Fully lower the reel and adjust the fore-aft

position between 5 and 6 on decal on the right

side reel arm.

c. Adjust center-link to mid-range (between B and

C on cylinder indicator).

d. Position cutterbar 8–12 in. (200–300 mm) off

the ground.

CAUTION

Stop engine, and remove key from ignition

before leaving Operator's seat for any

reason. A child or even a pet could engage

an idling machine.

e. Stop engine, and remove key from ignition.

f.

Check that adapter is level. If the adapter is not

level, perform the following checks prior to

adjusting the leveling linkages.

IMPORTANT

The adapter float springs are not

used to level the header.

Check combine tire pressures.

Check that the combine feeder house is

level. Refer to combine operator’s manual.

Check that top of adapter is level with

combine axle.

(continued next page)

A

LOCK

UNLOCK

B