4 electrical connections, power unit, Electrical connections, power unit, Table 19: tools 45 – NORD Drivesystems BU0505 User Manual

Page 45: Table 20: connection data, Notice, 2 assembly and installation, Brake voltage supply

2 Assembly and installation

BU 0505 GB-1013

45

2.10.4 Electrical connections, power unit

Before connecting the frequency inverter, the following must be observed:

1. Ensure that the mains supply provides the correct voltage and is suitable for the current required.

2. Ensure that suitable circuit breakers with the specified nominal current range are installed between

the voltage source and the inverter.

3. Connect the mains voltage directly to the mains terminals L1-L2/N-L3-PE (for each device)

4. A four-core cable must be used to connect the motor. The cable is connected to the motor

terminals PE-U-V-W.

5. If screened motor cables (recommended) are used, the cable screening must also be connected to

a large area of the metallic screening angle of the EMC Kit, however, at least to the electrically

conducting mounting surface of the control cabinet.

6. Above size 8, the cable lugs which are included in the scope of delivery must be used. After

crimping, these must be insulated with shrink hose.

Note

The use of shielded cables is essential in order to maintain the specified radio interference suppression level.

If certain wire end sleeves are used, the maximum cross-section which can be connected can be reduced.

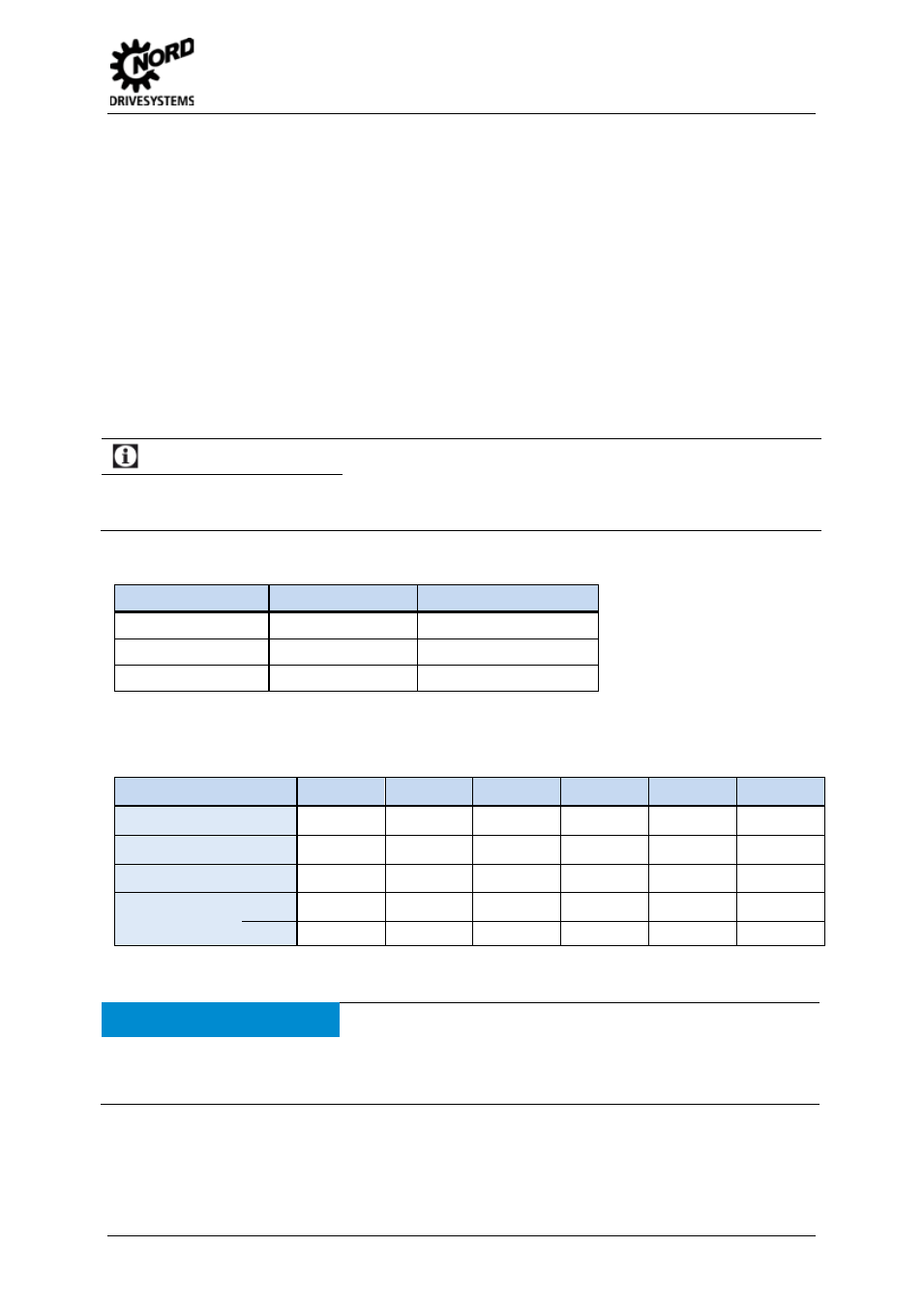

To connect the power unit, the following tools must be used:

Frequency inverter

Tools

Type

Size 1 - 4

Screwdriver

SL / PZ1; SL / PH1

Size 5 - 7

Screwdriver

SL / PZ2; SL / PH2

Size 8 - 9

Socket wrench

SW 13

Table 19: Tools

Connection data:

Frequency inverter

BG 1 ... 4

Size 5

Size 6

Size 7

Size 8

Size 9

Rigid cable Ø

[mm²]

0.2 … 6

0.5 … 16

0.5 … 35

0.5 … 50

50

95

Flexible cable Ø

[mm²]

0.2 … 4

0.5 … 10

0.5 … 25

0.5 … 35

50

95

AWG standard

24-10

20-6

20-2

20-1

1/0

3/0

Starting torque

[Nm]

0.5 … 0.6

1.2 … 1.5

2.5 … 4.5

2.5 … 4

15

15

[lb-in]

4.42 … 5.31

10.62 … 13.27

22.12 … 39.82

22.12 … 35.4

135

135

Table 20: Connection data

NOTICE

Brake voltage supply

The voltage supply for an electro-mechanical brake (or its brake rectifier) must be via the mains.

Connection to the output side (connection to the motor terminals) may cause the destruction of the brake or the

frequency inverter.

Pos : 52 /Anl eitungen/ Elektroni k/FU und Start er/ 2. M ont age und Ins tall ati on/ 2. 10. 4 Elektrischer Ansc hluss Leis tungst eil -Teil 1 - N etz ansc hlus s (X1) [ BU 0500] @ 1\ mod_1331195429990_388. doc x @ 17590 @ 5 @ 1