12 ratio control, Stoichiometric combustion, Ratio control – West Control Solutions Pro-EC44 User Manual

Page 88

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Pro-EC44 Product Manual - 59540-1 October 2013

Page 81

12 Ratio Control

A ratio control loop is used where the quantity of one of the material is to be controlled in

proportion to the measured quantity of a second material. The controller mixes the materials

at the desired ratio by adjusting the flow of input 1. The flow of input 2 may be controlled

separately, but is not controlled by the ratio control loop itself.

The process value used by the controller is therefore determined by the ratio of the two

inputs rather than a single measured variable.

Note: Ratio control is available on models with the 2

nd

Auxiliary Input, or two loop

models. The feature and information displayed is optimised for control of burner

fuel/air, but can be used in other flow ratio applications.

Stoichiometric Combustion

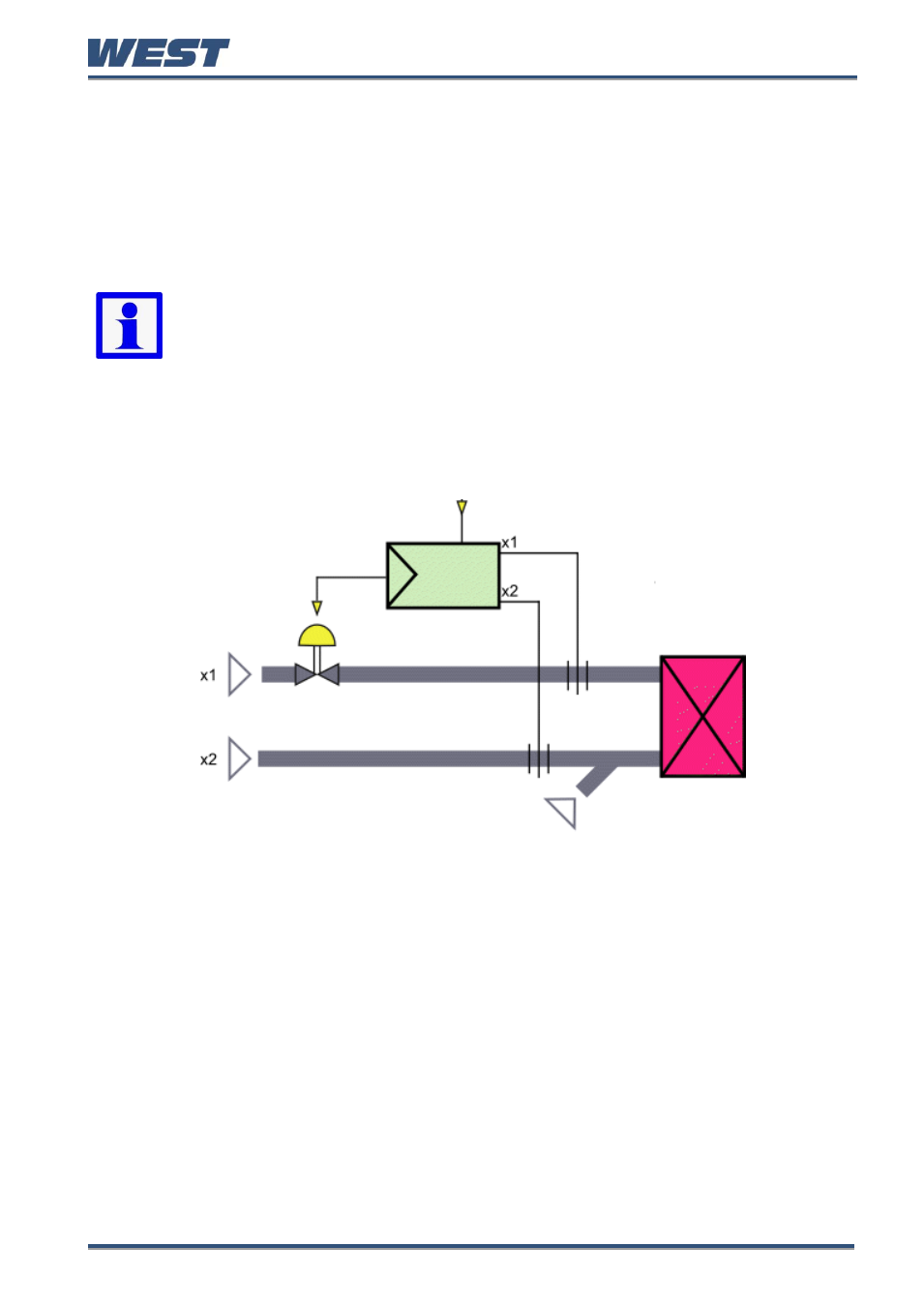

Below is an example of stoichiometric combustion ratio control. For optimum combustion the

fuel-air ratio is set so that there are no flammable residues in the waste gas.

Figure 48.

Ratio Control Example

It is normal in this application to display the process value and setpoint as relative values

rather than the physical ratio or absolute values. A scaling factor is set such that the

displayed value will be 1.00 at the correct stoichiometric ratio for the application.

Inputs 1 and 2 are configured and scaled to match the attached flow meters.

In this example a 4 to 20mA signal at x1 represents 0 to 1000m

3

/h of airflow controlled by a

valve. The second 4 to 20mA signal at x2 represents 0 to 100m3/h of fuel oil. The fuel flow is

not affected by this control loop.

Atomizing air is fed in with the fuel oil at a constant rate

‘NO’. This must be considered when

calculating the correct fuel/air mix. Total airflow is x1 + NO.

The stoichiometric factor, SFac is entered to match the desired ratio. E.g for 10 parts total

airflow to one part fuel, SFac would be 10.

The setpoint (entered as a relative value such as 1.00) is multiplied by SFac when

calculating the control deviation. E.g. with a setpoint of 1.00 and SFac of 10 the controller

Atomization Air

NO

Burner

Air

Fuel

Air Valve