West Control Solutions Pro-EC44 User Manual

Page 35

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Pro-EC44 Product Manual - 59540-1 October 2013

Page 28

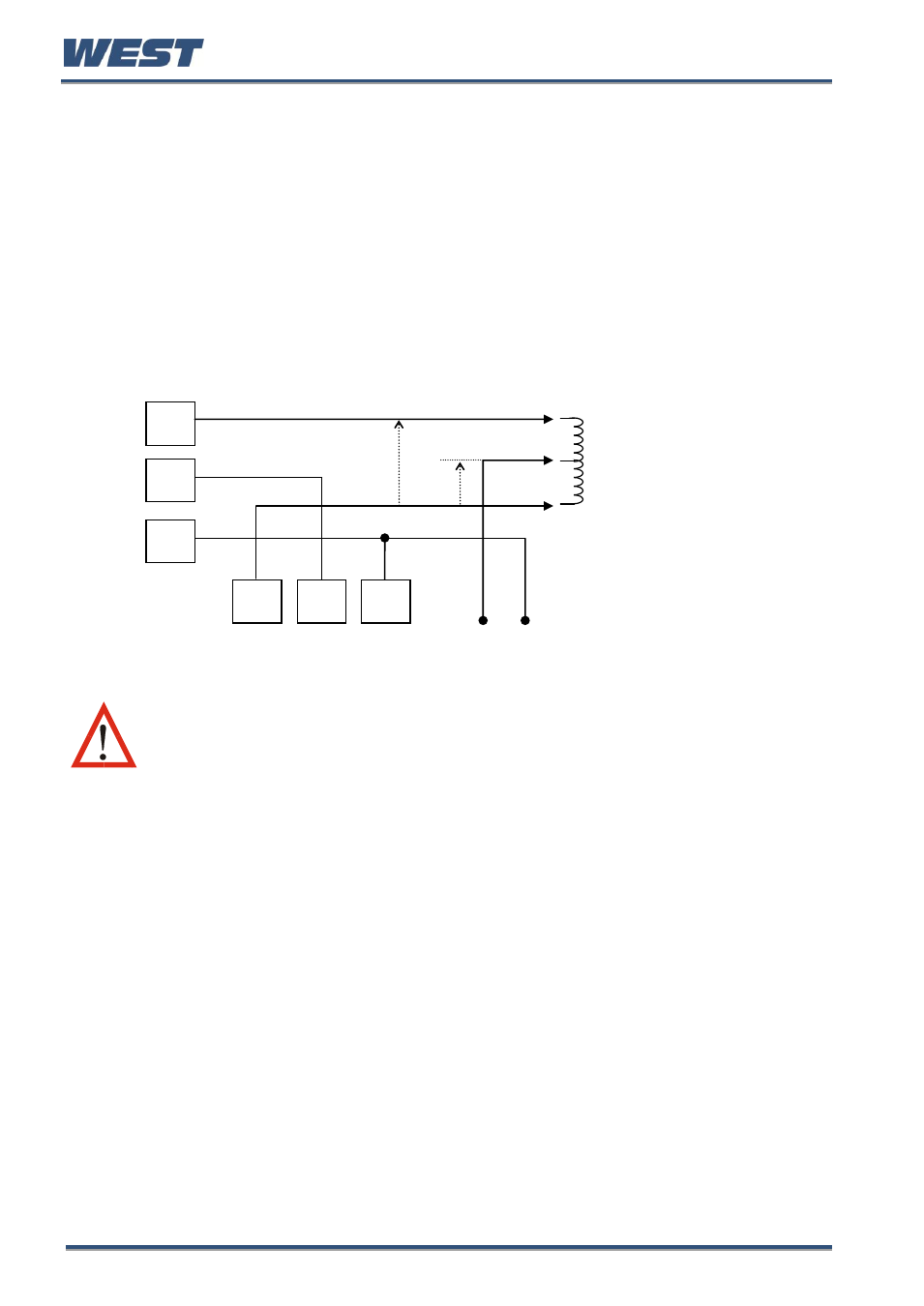

Special Wiring Considerations for Valve Motor Control

Valve Motor Drive (VMD) controllers require two identical outputs to be assigned to position

the valve. One to open and one to close the valve. These outputs can be two single relays,

two triacs, two SSR drivers or one dual relay, but it is recommended to use two single relays

(SPDT change-over contacts), and to interlock the relay wiring as shown. This prevents both

motor windings from being driven at the same time, even under fault conditions.

Switching actuators directly connected to the valve motor must only be used up to half of

their rated voltage (see

CAUTION

below). The internal relay and triac outputs are rated at

240VAC, so the maximum motor voltage when using them in this way is therefore 120V

unless interposing relays are used. Interposing relays or other devices used to control the

valve must themselves be rated for twice the motor supply voltage.

Figure 42.

Interlocking of Valve Motor Drive Relays

CAUTION:

The windings of a valve motor effectively form an

autotransformer. This has a voltage doubling effect when power is applied

to either the Open or Close terminal, causing twice the supplied voltage at

the other terminal. For this reason, switching devices directly connected to

the valve motor must only be used up to half of their rated voltage. The

maximum motor voltage when using the internal relays/triacs is therefore

120V unless interposing relays are used. Interposing relays or other devices

used to control the valve must themselves be rated for twice the motor

supply voltage.

Open Valve Winding

Close Valve Winding

Valve Common

“O

P

E

N”

RE

L

AY

N/O

C

N/C

N/C

C

N/O

“CLOSE” RELAY

N/C

C

N/O

120VAC SUPPLY

2 x 120V = 240V

120V