Integral time constant, Derivative time constant – West Control Solutions Pro-EC44 User Manual

Page 114

Pro-EC44 2-Loop Graphical Profile Controller & Recorder

Pro-EC44 Product Manual - 59540-1 October 2013

Page 107

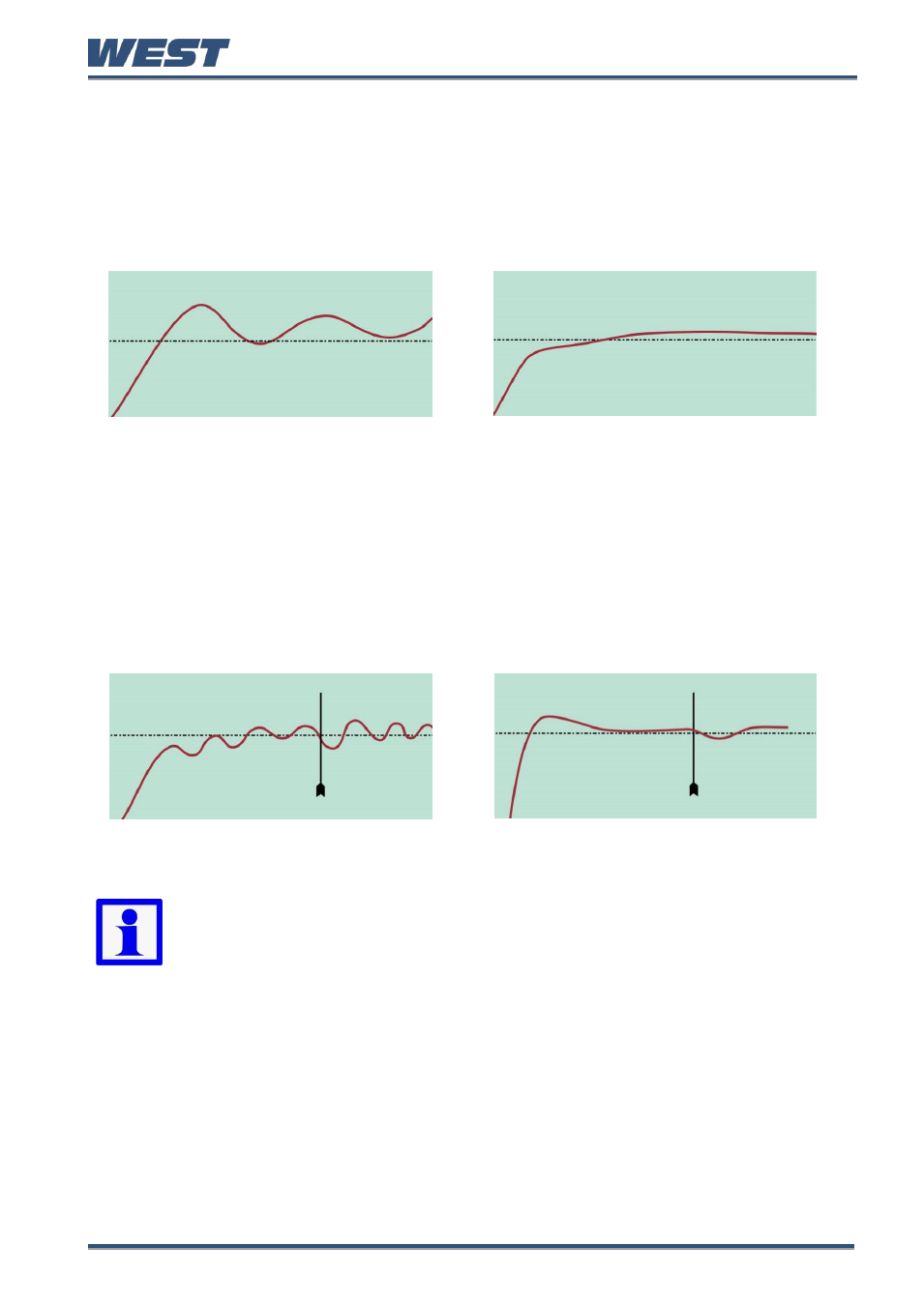

Integral Time Constant

To find the optimum integral time, decrease its value until the process becomes unstable,

then increase it a little at a time, until stability has is restored. Induce a load disturbance or

make a setpoint change to verify that the process stabilises. If not increase the value some

more and re-test. If the response is too slow, decrease the integral time, but avoid instability.

Integral Time

Too Short: Overshoots and oscillates

Too Long: Slow warm up and response

Derivative Time Constant

Initially set the derivative to between 1/4

th

and 1/10

th

of the Integral time value.

Increase the derivative time if the process overshoots/undershoots. Increase it a little at a

time, but if the process becomes unstable, decrease it until the oscillation stops. Induce a

load disturbance or make a setpoint change to verify that the process stabilises. If not

decrease the value some more and re-test.

Derivative Time

Too Long: Oscillates and over corrects

when process disturbed

Too Short: Slow warm up and disturbance

response under-corrects

Note: When controlling a modulating valve, it is usually recommended that

derivative is set to OFF to avoid excessive valve activity. Derivative can cause

process instability in these processes.

Process Disturbance

Process Disturbance